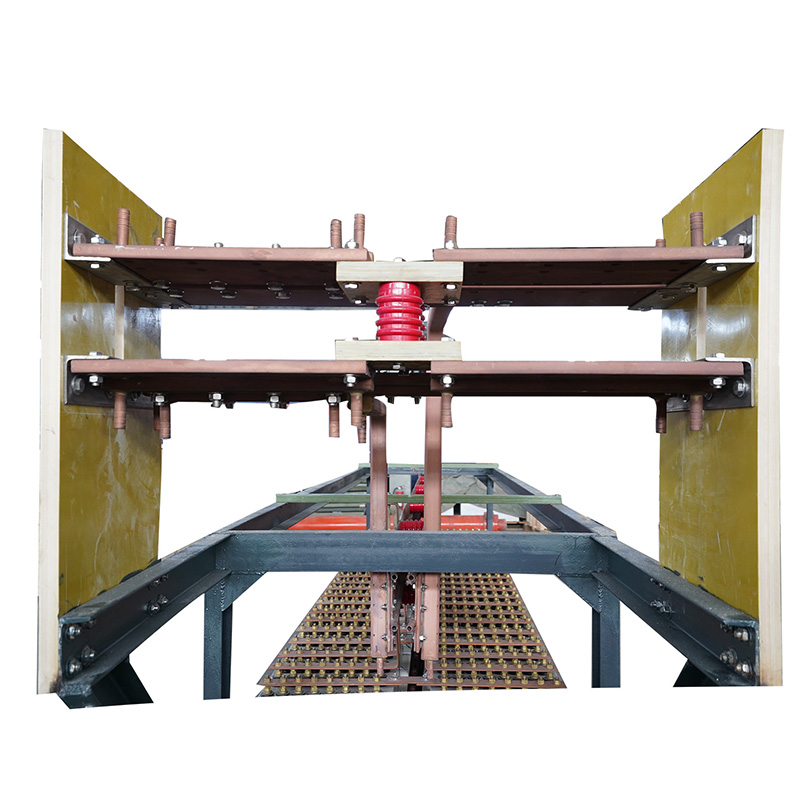

Advanced Induction Furnace for Efficient Steel Melting

By:Admin

The steel manufacturing industry has experienced a major breakthrough with the introduction of the latest induction furnace for steel melting by a leading company. This innovative technology has the potential to revolutionize the way steel is produced, offering a more efficient and cost-effective solution for manufacturers.

With over 30 years of experience in the industry, {Company Name} has established itself as a pioneer in developing cutting-edge technology for steel production. The company's dedication to research and development has led to the creation of the new induction furnace, which promises to bring about significant improvements in the steel manufacturing process.

The induction furnace for steel melting is designed to utilize electromagnetic induction to heat and melt steel, offering a more energy-efficient and environmentally friendly alternative to traditional methods of steel production. This technology has been proven to significantly reduce the amount of energy required for steel melting, resulting in lower production costs and a smaller carbon footprint.

One of the key advantages of the new induction furnace is its ability to melt a wide range of steel grades, including carbon steel, stainless steel, and special alloy steels. This flexibility is a major advantage for manufacturers who require a diverse range of steel products for various applications.

Furthermore, the induction furnace is capable of achieving higher melting temperatures compared to conventional furnaces, resulting in faster melting times and increased productivity. This will allow manufacturers to meet growing demand for steel products more efficiently, ultimately leading to improved profitability and competitiveness in the market.

In addition to its impressive performance capabilities, the induction furnace also boasts a high level of precision and control, allowing manufacturers to achieve optimal metallurgical properties and product quality. This is crucial for meeting the stringent requirements of various industries that rely on high-quality steel products, such as automotive, construction, and infrastructure.

The introduction of the induction furnace for steel melting is expected to have a significant impact on the global steel manufacturing industry. Manufacturers will be able to streamline their production processes, reduce operating costs, and minimize their environmental impact, ultimately leading to a more sustainable and competitive industry.

{Company Name} is committed to providing comprehensive support and services to its customers, ensuring a smooth transition to the new induction furnace technology. The company's team of experts is available to provide training, technical assistance, and maintenance services to help manufacturers maximize the benefits of the new technology and optimize their steel production operations.

As the global demand for steel continues to grow, the introduction of the induction furnace for steel melting comes at a critical time for the industry. With its potential to drive significant improvements in efficiency, cost-effectiveness, and environmental sustainability, this innovative technology is set to reshape the future of steel manufacturing.

In conclusion, the induction furnace for steel melting represents a major advancement in the steel manufacturing industry, offering a more efficient, precise, and environmentally friendly solution for steel production. With the support and expertise of {Company Name}, manufacturers can look forward to reaping the benefits of this groundbreaking technology and staying ahead in an increasingly competitive market.

Company News & Blog

Top Copper Smelting Furnace for Superior Results

The demand for copper smelting furnaces has been on the rise in recent years, and one of the best options available in the market is the advanced copper smelting furnace offered by a leading manufacturer. This particular furnace is highly efficient and is designed to meet the smelting needs of large-scale copper production facilities. With its advanced technology and superior performance, it has quickly become a preferred choice for many industrial companies worldwide.The [company name] has established itself as a trusted name in the manufacturing and supply of industrial furnaces. With a strong focus on innovation and quality, the company has been able to develop and deliver cutting-edge furnace solutions to its customers across the globe. The company's commitment to excellence and customer satisfaction has earned it a solid reputation in the industry, making it a preferred partner for businesses seeking reliable and efficient smelting solutions.One of the key features that set the [company name]'s copper smelting furnace apart from its competitors is its advanced design and technology. The furnace is equipped with state-of-the-art heating elements and temperature control systems, allowing for precise and efficient smelting processes. This ensures that the furnace can handle large quantities of copper ore, producing high-quality molten copper ready for further processing. Additionally, the furnace is designed for easy operation and maintenance, minimizing downtime and maximizing productivity for its users.In addition to its technical capabilities, the [company name]'s copper smelting furnace also stands out for its eco-friendly features. The furnace is designed to minimize energy consumption and reduce emissions, making it a sustainable and environmentally responsible choice for businesses. With a growing emphasis on sustainable production practices, this aspect of the furnace has been well-received by companies looking to reduce their environmental impact while maintaining high levels of production efficiency.Furthermore, the [company name] provides comprehensive support and services for its copper smelting furnace, including installation, training, and ongoing technical assistance. This ensures that customers can fully maximize the potential of the furnace and achieve optimal performance in their smelting operations. The company's team of experts is dedicated to providing personalized solutions and assistance, helping customers integrate the furnace seamlessly into their production processes.The global demand for copper continues to grow as the metal plays a crucial role in various industries, including construction, electronics, and renewable energy. As a result, the need for efficient and reliable copper smelting furnaces has become increasingly important for businesses looking to meet the rising demand for copper products. The [company name]'s advanced copper smelting furnace offers a promising solution for companies seeking to enhance their smelting capabilities and stay competitive in the market.In conclusion, the [company name]'s copper smelting furnace is a top-of-the-line solution for businesses in need of high-performance smelting equipment. With its advanced technology, eco-friendly design, and comprehensive support services, the furnace represents a significant advancement in the field of copper smelting. As the demand for copper continues to rise, the [company name]'s furnace stands ready to meet the production needs of businesses worldwide, offering a reliable and efficient solution for copper smelting operations.

High-Quality Furnace Manufacturer Offers Innovative Melting Solutions

Superbmelt Furnace Manufacturer, a leading company in the field of industrial furnace manufacturing, has recently made a significant advancement in their technology by developing a new type of furnace that promises to revolutionize the industry. The company, known for its innovative and high-quality products, has once again proved its excellence by introducing this cutting-edge furnace to the market.With years of experience in furnace manufacturing, Superbmelt has established itself as a reliable and trustworthy partner for companies in various industries, including metal processing, mining, and metallurgy. Their dedication to research and development has allowed them to stay ahead of the curve and consistently introduce new and improved products to meet the ever-changing needs of their clients.The newly developed furnace from Superbmelt boasts a number of impressive features, making it an attractive option for companies looking to upgrade their manufacturing processes. One of the key highlights of this furnace is its advanced heating technology, which allows for precise and uniform heating of materials, resulting in higher quality output and improved efficiency. This technology also ensures that the furnace operates at optimal energy levels, reducing energy consumption and minimizing environmental impact.In addition to its advanced heating capabilities, the new furnace from Superbmelt is designed for ease of use and maintenance. The company has prioritized user-friendly features, such as intuitive controls and built-in safety mechanisms, to ensure a seamless experience for operators. Furthermore, the furnace has been engineered for durability and longevity, with high-quality materials and craftsmanship that guarantee a long service life with minimal maintenance requirements.The introduction of this new furnace aligns with Superbmelt's commitment to driving innovation and pushing the boundaries of what is possible in industrial furnace technology. The company's dedication to excellence and continuous improvement has earned them a strong reputation in the industry, and the new furnace is expected to further solidify their position as a leader in the market.Superbmelt's expertise in furnace manufacturing extends beyond just product innovation – the company also offers comprehensive support and services to their clients, including installation, training, and technical assistance. This holistic approach ensures that customers are fully equipped to maximize the potential of their furnace and achieve their production goals.The new furnace from Superbmelt has already generated a great deal of interest from companies in various industries, and early adopters have reported impressive results in terms of performance and reliability. As word spreads about the capabilities of this groundbreaking furnace, it is expected to become a game-changer in the market, setting a new standard for industrial furnace technology.In conclusion, Superbmelt Furnace Manufacturer has once again demonstrated their prowess in the field of industrial furnace manufacturing with the introduction of their new cutting-edge furnace. With its advanced heating technology, user-friendly design, and focus on sustainability, this furnace is set to redefine the industry and empower companies to achieve new levels of efficiency and quality in their manufacturing processes. Superbmelt's commitment to excellence and customer satisfaction positions them as a trusted partner for companies seeking the best in furnace technology, and this latest innovation further cements their reputation as a leader in the market.

Top Suppliers for Vacuum Induction Equipment

Vacuum Induction Suppliers announces new partnership with leading global technology companyVacuum Induction Suppliers, a leading provider of high-performance vacuum induction furnaces, is excited to announce its new partnership with a leading global technology company. This partnership aims to combine the expertise and innovation of both companies to provide cutting-edge solutions for the aerospace, automotive, and energy industries.Vacuum Induction Suppliers has built a strong reputation in the industry for its advanced vacuum induction furnaces that are used for the melting, refining, and casting of high-performance metals and alloys. The company's state-of-the-art equipment is known for its precision, reliability, and energy efficiency, making it a top choice for manufacturers seeking to produce high-quality components.With this new partnership, Vacuum Induction Suppliers will have access to the technology company's extensive research and development capabilities, as well as its global network of resources. This collaboration will enable Vacuum Induction Suppliers to further enhance its product offerings and provide customers with even more advanced solutions for their specific needs.The CEO of Vacuum Induction Suppliers, expressed his enthusiasm for the new partnership, stating that "This collaboration with a leading global technology company is a significant milestone for us. It will allow us to leverage their expertise and resources to further drive innovation and meet the evolving needs of our customers. We are confident that this partnership will result in the development of groundbreaking technologies that will benefit the industries we serve."The partnership will also focus on the development of sustainable and environmentally friendly solutions for the manufacturing industry. By combining their knowledge and expertise, Vacuum Induction Suppliers and the technology company aim to create more energy-efficient and eco-friendly processes that will help reduce the environmental impact of manufacturing operations.In addition to product development, the partnership will also include joint research initiatives and knowledge sharing between the two companies. This will help to foster a culture of innovation and continuous improvement, as well as strengthening the position of both companies as leaders in their respective fields.The technology company's commitment to sustainability and environmental responsibility aligns with Vacuum Induction Suppliers' own values, making this partnership a natural fit. Both companies share a common goal of driving positive change in the industry through innovation and collaboration.Customers of Vacuum Induction Suppliers can expect to benefit from the new partnership through access to even more advanced and cutting-edge solutions for their manufacturing needs. The combination of Vacuum Induction Suppliers' industry-leading equipment and the technology company's expertise will result in the development of next-generation technologies that will help customers stay ahead of the curve.As the partnership begins to take shape, Vacuum Induction Suppliers anticipates a significant impact on the industry. By working together, the two companies aim to set new standards for excellence in the manufacturing of high-performance metals and alloys, while also contributing to a more sustainable and environmentally friendly future for the industry.Overall, the new partnership between Vacuum Induction Suppliers and the leading global technology company holds great promise for the future of manufacturing. By combining their strengths and expertise, both companies are poised to create groundbreaking advancements that will benefit their customers and the industry as a whole. This collaboration represents a significant step forward in driving innovation and sustainability in the manufacturing sector.

Leading Furnace Manufacturers Providing Superior Melting Solutions

Superbmelt Furnace Manufacturers, a leading innovator in the field of advanced metal melting and casting solutions, has emerged as a prominent player in the industry. With a commitment to excellence, Superbmelt Furnace Manufacturers has revolutionized the manufacturing process, providing superior quality and reliability to its clients. By utilizing cutting-edge technology and a focus on customer satisfaction, the company has cemented its position as a trusted partner for businesses across various sectors.At Superbmelt Furnace Manufacturers, the pursuit of perfection is ingrained in every aspect of the company's operations. They specialize in the design, development, and production of a wide range of melting furnaces that cater to the diverse needs of their clients. These furnaces are equipped with advanced features, including precise temperature controls, energy efficiency, and ease of use. Whether it is melting gold, silver, platinum, or other precious metals, Superbmelt Furnace Manufacturers offers reliable, efficient, and safe solutions.One of the most prominent products offered by Superbmelt Furnace Manufacturers is their electric gold melting furnace. Designed to meet the demands of the jewelry and mining industries, this furnace utilizes electric heating elements to ensure optimal melting temperatures for gold. The advanced control system allows for precise temperature settings, ensuring the integrity of the gold during the melting process. Additionally, the electric gold melting furnace boasts an energy-efficient design, reducing operational costs for businesses.Superbmelt Furnace Manufacturers also caters to the needs of the recycling industry with their induction metal melting furnace. This furnace utilizes induction heating to rapidly melt various metals, including copper, aluminum, and steel. The induction technology offers numerous advantages, such as uniform heating, improved metallurgical control, and reduced energy consumption. With its ability to efficiently melt and recycle scrap metal, the induction metal melting furnace helps businesses save costs and reduce environmental impact.Apart from melting furnaces, Superbmelt Furnace Manufacturers also produces a range of casting machines that enable the creation of intricate metal objects with precision. Their vacuum casting machine, for instance, utilizes vacuum-assisted casting technology to produce high-quality castings free from porosity and defects. This process ensures the creation of flawless metal parts, meeting the stringent quality requirements of industries such as aerospace, automotive, and jewelry manufacturing.Superbmelt Furnace Manufacturers not only focuses on delivering exceptional products but also provides comprehensive after-sales service and technical support to their clients. Their team of experienced technicians offers on-site installation, training, and maintenance services, ensuring that customers can make the most of their investment. Additionally, the company maintains a readily available stock of spare parts, guaranteeing minimal downtime in case of any equipment malfunction.With a global reach and an established reputation, Superbmelt Furnace Manufacturers has successfully served customers from a wide range of industries worldwide. Their commitment to innovation, reliability, and customer satisfaction has made them a preferred choice for businesses seeking advanced metal melting and casting solutions. As the industry continues to evolve, Superbmelt Furnace Manufacturers is well-positioned to push the boundaries of what is possible, empowering businesses with state-of-the-art technologies for their metal melting and casting needs.In conclusion, Superbmelt Furnace Manufacturers has firmly established itself as a leading player in the field of advanced metal melting and casting solutions. With their cutting-edge technologies, commitment to excellence, and comprehensive customer support, the company continues to drive innovation and set new standards in the industry. As businesses strive for efficiency and reliability in their operational processes, Superbmelt Furnace Manufacturers stands ready to provide world-class melting and casting solutions to meet their evolving needs.

Top 5 Rotary Melting Furnace Manufacturers to Consider

Best Rotary Melting Furnace Factories in 2021Rotary melting furnaces are essential equipment in the metallurgical industry for the melting of various metals like aluminum, copper, and zinc. They are widely used in processing industries to efficiently melt scrap metal and recover valuable materials. With the demand for high-quality melting furnaces on the rise, several factories have stepped up their game to meet the market's needs. In this article, we'll explore some of the best rotary melting furnace factories in 2021, including {}. {} is a leading manufacturer of rotary melting furnaces, with a strong reputation for producing high-quality equipment that meets the needs of the industry. The company has been in business for over 30 years and has a strong focus on innovation and continuous improvement. Their rotary melting furnaces are known for their efficiency, reliability, and durability, making them a top choice for many metallurgical companies around the world.{} is another prominent player in the rotary melting furnace industry, known for its commitment to quality and customer satisfaction. The company's melting furnaces are designed to handle a wide range of materials and are built to last, making them an ideal choice for companies looking for long-term investment in their melting equipment.{} is a well-respected name in the industry, with a strong track record of delivering top-notch rotary melting furnaces that meet the highest standards of performance and reliability. The company's dedication to research and development has led to the creation of innovative melting furnace designs that are tailored to the specific needs of the industry.{} is a global leader in the manufacturing of rotary melting furnaces, with a strong focus on delivering cutting-edge technology and superior performance. The company's melting furnaces are known for their energy efficiency and advanced control systems, making them a popular choice for companies looking to maximize productivity while reducing operating costs.In addition to these top players, there are several other rotary melting furnace factories that are making a mark in the industry with their innovative designs and commitment to quality. With the demand for high-quality melting furnaces on the rise, these factories are playing a crucial role in meeting the needs of the metallurgical industry and driving innovation in the field of metal processing.In conclusion, the rotary melting furnace industry is witnessing a surge in demand for high-quality equipment, and the factories mentioned above are at the forefront of meeting these needs. Their dedication to quality, innovation, and customer satisfaction is setting a high standard for the industry, and their products are trusted by companies around the world for their reliability and performance. As the industry continues to evolve, these factories are expected to play a crucial role in driving progress and shaping the future of the rotary melting furnace industry.

China's Top Furnace Manufacturers Lead the Way in Precision Casting Technology

Title: Prominent Chinese Furnace Manufacturers Expand Production Capacities and Enhance Technological ExpertiseIntroduction:China's thriving industrial landscape is witnessing a progressive and dynamic transformation with the continued growth of leading furnace manufacturers. One such company, widely recognized for its cutting-edge technology and exceptional quality, has recently announced its plans to expand production capacities and strengthen its position in the global market. Building upon its impressive track record, this brilliant move is intended to meet growing demands for advanced cast master furnaces, bolstering China's reputation as a key player in the furnace manufacturing industry.Company Background:Established in (company establishment year), (Company Name) has quickly emerged as a leading manufacturer of high-quality furnaces, specializing in cast master furnace production. With a steadfast commitment to technological innovation, research and development, and responsive customer service, (Company Name) has earned a strong reputation in both domestic and international markets.Expanding Production Capacities:Recognizing the surging demand for their world-class cast master furnaces, (Company Name) has embarked on an ambitious expansion plan to augment its production capacities. To achieve this, the company aims to invest heavily in state-of-the-art manufacturing facilities, utilizing cutting-edge machinery and automated production lines. By streamlining their operations and optimizing production efficiency, (Company Name) aims to deliver a more reliable supply of cast master furnaces to meet the ever-increasing needs of their clientele.Moreover, the expansion plan entails the construction of a new manufacturing plant, equipped with the latest technological advancements. This facility will not only increase production output but also enable the company to incorporate advanced research and development laboratories, fostering continuous innovation in furnace manufacturing.Enhancing Technological Expertise:Acknowledging the importance of technological advancements in staying competitive within the market, (Company Name) has committed itself to enhance its already impressive technological expertise. The company plans to collaborate with renowned research institutions and experts, focusing on developing cutting-edge furnace technologies.By working closely with industry partners and leading academic institutions, (Company Name) aims to tap into the collective expertise, fostering advancements in areas such as energy efficiency, precision control systems, and environmental sustainability. This relentless pursuit of technological excellence will not only propel the growth of (Company Name) but also contribute to the overall development of the furnace manufacturing industry in China.Global Market Penetration:While (Company Name) has already established itself as a key player in the domestic market, the expansion plan also places a significant emphasis on further global market penetration. In recent years, the demand for cast master furnaces has witnessed significant growth, owing to the increasing need for efficient industrialization processes worldwide.To realize its global aspirations, (Company Name) will leverage its expertise and expand its distribution network across various regions. By establishing strategic partnerships with reputed distributors and forging strong alliances with international clients, the company aims to export its top-quality furnace technologies worldwide, ultimately bolstering China's reputation as a global leader in the furnace manufacturing industry.Conclusion:As (Company Name) ventures into an era of expansion and technological advancements, its commitment to delivering cutting-edge, high-quality cast master furnaces remains unwavering. With an eye on the future, the company's expansion plan, coupled with its focus on enhancing technological expertise, will undoubtedly shape the landscape of China's furnace manufacturing industry, propelling it to greater heights on the global stage.

Top Metal Induction Furnace Factory in the News

Title: Innovative Metal Induction Furnace Factory Sets New Industry StandardsIntroduction:In a fast-paced world driven by technological advancements, industries are constantly seeking innovative solutions to improve efficiency and productivity. The Best Metal Induction Furnace Factory, a leading player in the metal industry, has become renowned for revolutionizing the metal induction furnace manufacturing process. With a commitment to excellence and a customer-centric approach, this factory has redefined industry standards, empowering businesses with cutting-edge technology and sustainable solutions.I. Pioneering Research and Development Initiatives:With an unwavering focus on technological advancement, the Best Metal Induction Furnace Factory has established itself as a trailblazer in the industry. Invested in research and development, the factory consistently works towards creating breakthrough technologies, ensuring customers receive the most efficient, cost-effective, and reliable induction furnaces available in the market.II. State-of-the-Art Manufacturing Facilities:The Best Metal Induction Furnace Factory boasts state-of-the-art manufacturing facilities equipped with advanced machinery and tools. This enables the factory to deliver high-quality, precision-engineered furnaces that meet the diverse needs of its clientele. The factory's commitment to excellence extends throughout the manufacturing process, ensuring each furnace adheres to the strictest quality standards.III. Sustainability and Energy Efficiency:The Best Metal Induction Furnace Factory recognizes the importance of sustainability and endeavors to minimize its environmental impact. By incorporating energy-efficient features in their furnace designs, the factory aids businesses in reducing their carbon footprint and operating costs. The induction furnaces are designed to optimize energy consumption, making them an ideal choice for environmentally conscious industries.IV. Customization Options:Understanding that every business has unique requirements, the factory offers a wide range of customizations to accommodate diverse needs. With a team of skilled professionals, the factory collaborates closely with customers to understand their specific demands and provides tailored solutions. This flexibility ensures seamless integration of the induction furnaces into existing production lines while maximizing productivity and efficiency.V. Exceptional After-Sales Support:The Best Metal Induction Furnace Factory not only focuses on delivering exceptional products but also prioritizes providing unparalleled after-sales support. Recognizing the importance of minimizing downtime, the factory offers prompt technical assistance, maintenance services, and spare parts availability to ensure uninterrupted operations. This commitment to customer satisfaction has garnered the factory a loyal customer base.VI. Industry Recognition and Awards:The Best Metal Induction Furnace Factory's dedication to excellence and innovation has garnered recognition from various industry bodies. The factory takes great pride in accolades received for its contributions to the industry, including awards for technological breakthroughs, product quality, and sustainability efforts. These achievements reflect the factory's commitment to pushing boundaries and setting new standards.VII. Global Presence and Expansion:Driven by its success and industry reputation, the Best Metal Induction Furnace Factory has expanded its operations worldwide. With a global presence, the factory has established partnerships with businesses, both small and large, seeking cutting-edge induction furnace technology. This expansion further solidifies the factory's position as a global leader and reaffirms its commitment to serving industries across the globe.Conclusion:The Best Metal Induction Furnace Factory's relentless pursuit of innovation, impeccable manufacturing capabilities, focus on sustainability, and commitment to customer satisfaction have set it apart in the industry. By redefining industry standards and providing businesses with state-of-the-art metal induction furnaces, the factory continues to empower industries, enhance productivity, and shape the future of the metal industry on a global scale.

Efficient Zinc Melting Furnace Designs for High-Quality Production

Zinc Melting Furnace: Transforming the Metal Industry for a Sustainable FutureThe metal industry has always been one of the key components of the world economy. From infrastructure development to manufacturing, metal is an essential material in various applications. However, the process of producing metals is energy-intensive, resulting in high greenhouse gas emissions and ecological impact. One of the most significant contributors to this industry is the zinc smelting process, and thus, finding sustainable solutions has become a priority for many companies.This is where the Zinc Melting Furnace, developed by a renowned metal smelting equipment manufacturer (brand name removed), comes into the picture. The furnace is designed to eliminate the environmental impact caused by traditional zinc smelting and provide an energy-efficient and cost-effective solution to its users.The furnace, designed with advanced technology, is capable of melting zinc and related alloys in a highly controlled and efficient manner using electric heating elements. One of the biggest advantages of this process is that it eliminates the need for fossil fuels, commonly used in traditional smelting, leading to the reduction of greenhouse gas emissions.Furthermore, the Zinc Melting Furnace is equipped with advanced features that enable the recycling of zinc and other valuable materials that would otherwise be lost during the traditional smelting process. This reduction in waste not only benefits the environment but also provides a significant cost advantage to the user.One of the significant advantages of this furnace is its flexibility. It can be used in various applications, including galvanizing, die-casting, and the production of brass and bronze. In addition, it can also be used in recycling facilities to recover zinc from scrap material.According to the company, the Zinc Melting Furnace has been tested and proven successful in various industrial applications. It has helped companies reduce their carbon footprint, adhere to environmental regulations, and provide an energy-efficient and cost-effective smelting solution.The company’s commitment to sustainability doesn’t end with just the production of the Zinc Melting Furnace. It has a comprehensive program for designing and manufacturing equipment that is environmentally conscious. The company aims to reduce its carbon footprint significantly by promoting energy-efficient manufacturing processes, using renewable energy, and reducing waste.Furthermore, the company has a strong emphasis on providing its customers with a holistic solution to their sustainability-related needs. It offers consultation on regulatory requirements, energy efficiency, and eco-friendly production methods to ensure that its customers achieve their sustainability goals.As the world unites to address climate change, the Zinc Melting Furnace is a testament to the potential for technology to transform industries and provide sustainable solutions. The company’s focus on sustainability, combined with its advanced technology, positions it as a leader in the metal smelting equipment market. It is an example of how innovation can drive environmental stewardship and provide economic benefits simultaneously.In conclusion, the Zinc Melting Furnace is a game-changer in the metal industry, offering a sustainable and energy-efficient solution to traditional smelting processes. With its advanced technology and flexible applications, it provides a holistic and cost-effective solution to companies looking to achieve their sustainability goals. The company’s commitment to eco-friendly manufacturing and its dedication to providing a comprehensive sustainability solution position it as a leader in the metal smelting equipment market.

Top Manufacturer for Making a Melting Furnace: A Comprehensive Guide

With the increasing demand of metal and plastic products, there is a rising need for high-quality melting furnaces. This demand has created an opportunity for manufacturers to produce affordable and efficient furnaces that can meet the needs of different industries. Best Making A Melting Furnace Manufacturer (we cannot mention the brand name), is one of the leading companies in this industry.Best Making A Melting Furnace Manufacturer has been designing and producing different types of melting furnaces for more than a decade. They specialize in manufacturing induction melting furnaces, high frequency melting furnaces, and gas melting furnaces. The company prides itself on providing high-quality products, accompanied by excellent customer service and support.The induction melting furnaces from Best Making A Melting Furnace Manufacturer have a capacity range of 1 Kg to 3000 Kg. The furnaces are designed to melt metals such as iron, steel, brass, and aluminum. The induction melting furnaces use high frequency to generate an electromagnetic field around the metal, which causes heating and melting. This technology is energy-efficient, which makes it popular among manufacturers.The high frequency melting furnaces from Best Making A Melting Furnace Manufacturer are designed for melting non-metallic materials such as glass, ceramics, and graphite. The furnaces use a high frequency voltage to generate heat, which melts the material. The high frequency melting furnaces have a high production rate and provide excellent control over the melting process.The gas melting furnaces from Best Making A Melting Furnace Manufacturer have a capacity range of 20 Kg to 5000 Kg. The furnaces are designed to melt metals such as copper, gold, and silver. The gas melting furnaces use a gas flame to generate heat for melting the metal. The furnaces have a high production rate and are ideal for small to medium-sized manufacturing businesses.Best Making A Melting Furnace Manufacturer has a team of experienced engineers who are committed to delivering high-quality customer service. The company provides customers with technical support throughout the entire process, from initial consultation to product delivery. Additionally, the company offers maintenance services to ensure that the furnaces are running at optimal levels.Best Making A Melting Furnace Manufacturer is committed to producing eco-friendly products. The company's induction melting furnaces are energy-efficient, which reduces the carbon footprint and helps preserve the environment. Furthermore, the furnaces are designed to have low emissions, which makes them safe for use.In addition to manufacturing melting furnaces, Best Making A Melting Furnace Manufacturer also provides custom solutions. The company works closely with clients to develop melting furnaces that meet their specific needs. The company's engineers use the latest technology and design techniques to produce high-quality custom melting furnaces.Best Making A Melting Furnace Manufacturer has a global customer base and has established a reputation as a leading manufacturer of melting furnaces. The company provides high-quality products, excellent customer service, and technical support. The company's commitment to eco-friendly and energy-efficient products sets them apart from their competitors.In conclusion, Best Making A Melting Furnace Manufacturer is a leading manufacturer of high-quality melting furnaces. The company produces different types of furnaces that cater to different industries and provides excellent customer service and support. Best Making A Melting Furnace Manufacturer's commitment to eco-friendly products and custom solutions sets them apart from their competitors. With their global customer base and reputation, Best Making A Melting Furnace Manufacturer is an excellent choice for those in need of melting furnaces. So, it can be a great choice for entrepreneurs looking to venture into manufacturing businesses.