Guide to Aluminum Induction Furnace: Technology, Benefits, and Applications

By:Admin

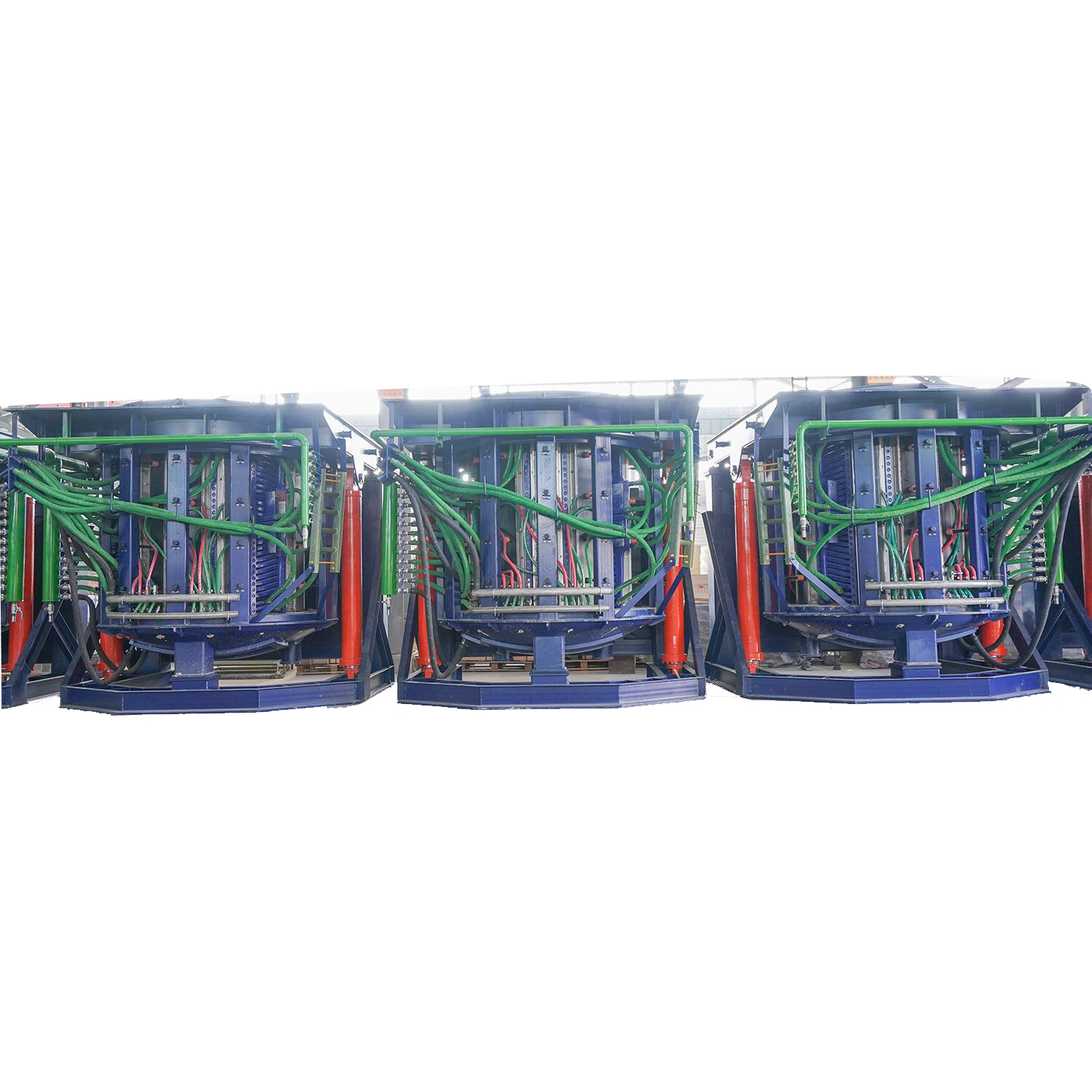

AIF's aluminum induction furnaces are designed to provide superior performance and reliability. The advanced technology used in these furnaces allows for precise temperature control and uniform heating, resulting in high-quality aluminum products. The induction heating process also ensures energy efficiency, reducing operational costs for companies using AIF's furnaces.

One of the key advantages of AIF's aluminum induction furnaces is their ability to handle a wide range of aluminum alloys. Whether it's primary or secondary aluminum, AIF's furnaces can efficiently melt and cast various alloys, meeting the diverse needs of the metal industry. This versatility makes AIF's furnaces a valuable asset for companies working with different types of aluminum materials.

In addition to their superior performance, AIF's aluminum induction furnaces are also known for their durability and low maintenance requirements. The robust construction and high-quality components used in these furnaces ensure long-term reliability, minimizing downtime and production interruptions for companies using AIF's equipment.

AIF's commitment to innovation and continuous improvement is reflected in its ongoing research and development efforts. The company's engineering team works tirelessly to enhance the performance and capabilities of its aluminum induction furnaces, staying ahead of industry trends and meeting the evolving needs of its customers.

Furthermore, AIF's dedication to customer satisfaction sets it apart in the industry. The company prides itself on providing comprehensive support and service to its clients, ensuring that their needs are met and their expectations are exceeded. From initial consultation to installation and ongoing maintenance, AIF's team is available to assist its customers every step of the way.

With its proven track record and strong reputation in the industry, AIF has established itself as a leading provider of aluminum induction furnace solutions. The company's commitment to quality, innovation, and customer satisfaction has earned it the trust of numerous companies in the metal industry, making AIF the go-to choice for aluminum melting and casting needs.

As the demand for high-quality aluminum products continues to grow, AIF remains at the forefront of the industry, offering cutting-edge solutions to help companies meet their production goals and stay competitive in the market. With its dedication to excellence and relentless pursuit of innovation, AIF is poised to shape the future of the metal industry and set new standards for aluminum melting and casting technology.

In conclusion, AIF's aluminum induction furnaces are a testament to the company's unwavering commitment to excellence and its ability to deliver superior solutions that empower the metal industry to thrive. With its advanced technology, versatile capabilities, and exceptional service, AIF continues to be a trusted partner for companies looking to elevate their aluminum production processes. As the industry evolves, AIF remains a driving force, setting new benchmarks for performance, efficiency, and reliability in aluminum melting and casting.

Company News & Blog

Premium Melting Furnace Services for Expert Plumbers

Best Plumbers Melting Furnace is excited to announce the launch of their latest innovation in melting furnace technology. The company has been a leading provider of melting furnaces for over 20 years, and their newest product promises to revolutionize the industry.Founded in 1998, Best Plumbers Melting Furnace has quickly become a trusted name in the melting furnace industry. Their commitment to quality and innovation has set them apart from their competitors, and their new product is a testament to their dedication to excellence.The new melting furnace features a state-of-the-art design that is more efficient and powerful than any other furnace on the market. With cutting-edge technology and superior materials, this furnace is capable of melting a wide range of metals with precision and speed. Its advanced insulation and heating elements ensure uniform heating and precise temperature control, making it the ideal choice for any melting application.In addition to its unmatched performance, the new melting furnace is also designed with user convenience in mind. Its intuitive controls and user-friendly interface make it easy to operate, and its compact size allows for easy installation in any workspace. The furnace is also equipped with advanced safety features to ensure the protection of its operators and the surrounding environment.The team at Best Plumbers Melting Furnace is proud to offer this new product to their customers and is confident that it will exceed expectations. "We are thrilled to introduce our latest melting furnace to the market," said a representative from the company. "We have put countless hours of research and development into creating a product that is truly best-in-class, and we are excited to see the impact it will have on our customers' operations."The new melting furnace is now available for purchase, and the team at Best Plumbers Melting Furnace is ready to assist customers with any questions or inquiries they may have. With their extensive knowledge and expertise in melting furnace technology, customers can trust that they will receive the best guidance and support when choosing the right furnace for their specific needs.For over two decades, Best Plumbers Melting Furnace has been providing top-quality products and unparalleled customer service to businesses in the metal melting industry. With a focus on innovation and continuous improvement, the company has solidified its reputation as a leader in the industry and continues to set the standard for excellence.As the demand for melting furnace technology continues to grow, Best Plumbers Melting Furnace remains committed to staying ahead of the curve and delivering cutting-edge solutions to their customers. Their new melting furnace is just the latest example of their dedication to pushing the boundaries of what is possible in melting technology.With its unmatched performance, user-friendly design, and commitment to safety, the new melting furnace from Best Plumbers Melting Furnace is sure to be a game-changer for businesses in the metal melting industry. Customers can trust that they are investing in a product that will deliver exceptional results and set a new standard for melting efficiency and precision.For more information about Best Plumbers Melting Furnace and their new melting furnace, visit their website or contact their team directly. With their expertise and commitment to excellence, they are ready to assist businesses in finding the perfect melting furnace solution for their specific needs.

High Quality Induction Crucible Furnace for Metal Melting and Casting

Induction Crucible Furnace: The Future of Metal SmeltingThe metal smelting industry has long been searching for more efficient and environmentally friendly ways to produce metals. This has led to the development of induction crucible furnaces, a revolutionary technology that is poised to change the way metals are smelted. These furnaces are designed to be highly efficient, producing less waste and emissions than traditional smelting methods.One company at the forefront of this technology is {} company, a leading manufacturer of induction crucible furnaces. {} company has been in the business of developing and producing industrial equipment for over 30 years, and they have recently introduced their latest innovation: the Induction Crucible Furnace.The Induction Crucible Furnace is a state-of-the-art smelting system that uses electromagnetic induction to heat and melt metal. This technology offers several advantages over traditional smelting methods. For one, it is highly energy-efficient, leading to lower operating costs and reduced environmental impact. Additionally, the induction crucible furnace can be used to smelt a wide range of metals, making it a versatile and practical solution for metal producers.One of the key benefits of the induction crucible furnace is its ability to produce high-quality metal with minimal impurities. This is achieved through precise temperature control and uniform heating, resulting in a more consistent and reliable final product. Furthermore, the furnace's closed-loop system minimizes the release of harmful emissions, making it a much greener alternative to traditional smelting methods.In addition to its environmental benefits, the Induction Crucible Furnace also offers greater operational flexibility. Its modular design allows for easy customization and integration into existing production lines. This means that metal producers can easily upgrade their smelting operations without having to overhaul their entire infrastructure.{} company is proud to be leading the way in the development of this groundbreaking technology. With their extensive experience in industrial equipment manufacturing, they have been able to bring the induction crucible furnace to market in a relatively short amount of time. The company's dedication to research and development has resulted in a product that is poised to revolutionize the metal smelting industry.The induction crucible furnace is already generating a great deal of interest within the metal smelting industry. Many producers are eager to adopt this new technology in order to improve the efficiency and sustainability of their operations. With its potential to significantly reduce energy consumption and emissions, the induction crucible furnace is likely to become the standard for metal smelting in the near future.{} company is committed to supporting their customers in the adoption of this new technology. They offer comprehensive training and support services to ensure that their induction crucible furnaces are seamlessly integrated into their customers' operations. Furthermore, they are constantly researching and developing new features and improvements for their furnaces, ensuring that their customers have access to the latest advancements in metal smelting technology.In summary, the induction crucible furnace represents a major leap forward for the metal smelting industry. Its energy-efficient, environmentally friendly design, coupled with its ability to produce high-quality metal, make it a game-changer for metal producers around the world. With {} company leading the way in its development and implementation, the future of metal smelting looks brighter than ever.

Digital Electric Melting Furnace Manufacturer in China

Title: China's Leading Digital Electric Melting Furnace Manufacturer Revolutionizes the Industry with High-Quality and Efficient SolutionsIntroduction: With the increasing demand for advanced manufacturing technologies, China's digital electric melting furnace industry has been rapidly evolving to meet the needs of various sectors. Amongst the notable manufacturers, one company stands out for its innovative solutions, superior quality, and commitment to sustainability. Leveraging cutting-edge technology, the China-based manufacturer has been at the forefront of transforming the melting furnace industry by introducing diverse products that cater to a wide range of industrial applications.Article:(Opening paragraph)Digital electric melting furnace manufacturer, (brand name removed), has been a trusted industry leader in China for several years. Established with a vision to provide efficient and sustainable solutions, the company has successfully paved its way to become one of the most reputable manufacturers in the market. Focusing on advanced technologies, precision engineering, and superior performance, (brand name removed) has revolutionized the melting furnace industry.(Body paragraphs)1. Technology-Driven Innovations:Setting itself apart from traditional melting furnaces, (brand name removed) has embraced digitalization and automation to enhance the overall efficiency and productivity of its products. Employing state-of-the-art technology, such as IoT integration and smart controls, the company ensures precise temperature controls, reduced energy consumption, and minimal heat loss. These innovations result in significant cost savings for businesses while reducing their carbon footprint.2. Wide Range of Applications:Recognizing the diverse needs of its customers, (brand name removed) offers a comprehensive range of digital electric melting furnaces suitable for various industries. Whether it is for the production of metals, alloys, or specialized materials, the company's furnaces provide consistent and reliable performance. Additionally, these furnaces offer flexibility in terms of melting capacity, allowing businesses of all sizes to benefit from their advanced manufacturing capabilities.3. Enhanced Safety and Durability:Safety is a paramount concern in industrial settings, and (brand name removed) upholds this principle by incorporating multiple safety features in their melting furnace designs. From advanced insulation technology to automatic shutdown mechanisms, the company ensures that the furnaces are reliable, secure, and easy to operate. Moreover, (brand name removed) guarantees the longevity of their products through a combination of high-quality materials and rigorous quality control measures, offering customers peace of mind and long-term value.4. Commitment to Sustainability:In an era of increased environmental consciousness, (brand name removed) stands out for its dedication to sustainable manufacturing practices. By leveraging energy-efficient designs and environmentally friendly materials, the company reduces energy consumption and minimizes harmful emissions. Furthermore, (brand name removed) emphasizes recycling and waste reduction while actively engaging in research and development to further enhance its products' eco-friendly attributes.5. Customer-Centric Approach:Setting itself apart from competitors, (brand name removed) is renowned for its commitment to exceptional customer service. The company's knowledgeable and responsive staff ensures prompt answers to customer inquiries and provides expert assistance throughout the buying process. Furthermore, (brand name removed) offers customizable solutions to meet specific requirements, further strengthening its relationship with clients and supporting their long-term success.(Conclusion)As the leading digital electric melting furnace manufacturer in China, (brand name removed) sets an impressive benchmark for the industry. With their innovative technologies, focus on sustainability, and customer-centric approach, the company continues to provide high-quality and efficient solutions to industrial sectors worldwide. As the manufacturing landscape evolves, (brand name removed) stands ready to meet emerging trends and challenges, remaining at the forefront of the industry's progress.

Efficient and Reliable Smelting Furnace: Exploring Advanced Features and Benefits

[Title]: Next-Gen Smelting Furnace Revolutionizes Industrial Processes[Subtitle]: Cutting-edge technology boosts efficiency and minimizes environmental impact[Date]: [Enter Date][City, Country] - Industrial manufacturers seeking to optimize their operations and reduce their environmental footprint can now rely on the groundbreaking advancements offered by the latest smelting furnace developed by [Company Name]. This cutting-edge technology represents a major leap forward in smelting processes, enabling companies to achieve higher efficiency, lower energy consumption, and improved sustainability.Committed to innovation and continuous improvement, [Company Name] has revolutionized the smelting process by introducing their next-generation furnace. This advanced system is designed to meet the needs of various industries, including metal production, manufacturing, and recycling, and is equipped with state-of-the-art features that streamline operations and drive overall productivity.One of the key features of the new smelting furnace is its remarkable efficiency. Through advanced control algorithms and optimized heat distribution, the furnace can achieve higher metal yield rates, minimizing waste and maximizing resource utilization. This enhanced efficiency directly translates into significant cost savings for industrial manufacturers, boosting their competitiveness in the market.Moreover, the cutting-edge furnace technology enables precise temperature control and reduces the overall smelting time. This means companies can extract metals quicker than ever before, ultimately improving their production capacity and meeting the growing demands of their customers. The increased speed of the smelting process also leads to energy savings and reduced production cycle times, further enhancing overall manufacturing efficiency.In line with the global push for sustainable practices, the new smelting furnace helps industries minimize their environmental impact. With its advanced filtration systems and exhaust gas treatment mechanisms, the furnace effectively captures harmful pollutants, thereby significantly reducing emissions. By utilizing this groundbreaking technology, companies can comply with stringent environmental regulations and demonstrate their commitment to a greener future.Another remarkable aspect of the next-gen smelting furnace is its versatility. The furnace is capable of processing a wide range of materials, including various metals and alloys, providing manufacturers with the flexibility to adapt to evolving market demands. Additionally, its modular design allows for easy installation and integration into existing production lines, minimizing downtime and maximizing operational efficiency.[Company Name] remains dedicated to providing end-to-end solutions and exceptional customer service. With the new smelting furnace, the company offers comprehensive support, ranging from initial consultation to installation, commissioning, and ongoing maintenance. Industry players can rely on [Company Name]'s renowned expertise to optimize their smelting processes and achieve outstanding performance."As a company committed to delivering cutting-edge solutions, we are extremely proud to introduce our latest smelting furnace. This innovative technology represents a significant milestone in the industry, enabling companies to enhance their efficiency while reducing their environmental impact," said [Company Spokesperson]. "We firmly believe that this next-gen furnace will play a pivotal role in revolutionizing industrial processes and contributing to a more sustainable future."With the new smelting furnace, [Company Name] has once again pushed the boundaries of innovation in the industrial sector. By harnessing advanced technologies and adopting sustainable practices, companies can unlock greater efficiency, higher productivity, and a more sustainable manufacturing future. The introduction of this groundbreaking technology is a testament to [Company Name]'s ongoing commitment to driving change and empowering industries worldwide.

Top Copper Scrap Melting Furnace Manufacturers

Title: Prominent Copper Scrap Melting Furnace Manufacturers Emerge in the MarketIntroduction:The growing demand for copper, coupled with the emphasis on sustainable practices, has fueled the need for advanced technology in the recycling industry. Leading manufacturers are stepping up to meet this demand by developing innovative copper scrap melting furnaces. With a focus on energy efficiency, productivity, and environmental conservation, these manufacturers are revolutionizing the copper recycling industry. This article will highlight some of the best copper scrap melting furnace manufacturers who are making significant strides in the market.1. Company A:Company A has emerged as a force to be reckoned with in the copper scrap melting furnace market. Utilizing state-of-the-art technology, their furnaces are designed to maximize energy efficiency while minimizing emissions. The company's commitment to sustainable practices is evident through their incorporation of advanced filtration systems, resulting in reduced air pollution.With a strong track record in the industry, the company has earned a solid reputation for producing reliable and durable copper scrap melting furnaces. Moreover, Company A places a strong emphasis on customer satisfaction by offering comprehensive customer support and maintenance services, ensuring seamless operations for their clientele.2. Company B:Company B prides itself on its ability to offer tailored solutions to meet specific customer requirements. Their copper scrap melting furnaces are customizable, allowing businesses to optimize their operations to suit their specific needs. Recognizing the importance of efficiency and cost-effectiveness, Company B has incorporated cutting-edge technology into their designs to enhance productivity while minimizing energy consumption.The company's commitment to quality is further reflected in their attention to detail during the manufacturing process. Each furnace undergoes rigorous testing, ensuring that only top-notch products reach the market. Customer feedback plays a significant role in their continuous improvement strategy, allowing Company B to constantly innovate and enhance their offerings.3. Company C:Company C sets itself apart by combining years of experience with a commitment to sustainability. Their copper scrap melting furnaces are designed to exceed industry standards, utilizing advanced features such as intelligent automation and accurate temperature control. This results in optimized energy consumption and reduced waste generation during the melting process.The company's expertise in energy management and emissions control ensures compliance with environmental regulations. Additionally, Company C focuses on continuous research and development, incorporating the latest technological advancements into their products. This allows customers to benefit from enhanced efficiency, reduced downtime, and improved operational control.4. Company D:Company D has established a strong presence in the copper scrap melting furnace market by prioritizing customer-centric solutions. Their furnaces are engineered to deliver exceptional performance, catering to a broad range of customer requirements. By adopting a holistic approach, virtual simulations enable the company to offer innovative designs that optimize melting efficiency.Additionally, Company D offers comprehensive after-sales support, including installation, training, and maintenance services. Their commitment to service excellence has garnered them a loyal customer base and positioned them as a reliable partner in the copper recycling industry.Conclusion:The copper scrap melting furnace market has witnessed significant advancements from prominent manufacturers. Companies A, B, C, and D have demonstrated their commitment to sustainability, energy efficiency, and customer satisfaction. By offering innovative and customizable solutions, these manufacturers are leading the way in revolutionizing the copper recycling industry. With continued investment in research and development, these companies are sure to shape the future of copper scrap melting furnaces, further contributing to the circular economy.

Affordable and Reliable Smelting Machines Now Available for Sale

Title: Revolutionary Smelting Machine Offers Cutting-Edge Solutions to Industrial SectorIntroduction:In the world of industrial manufacturing, advancements in technology continue to shape the way businesses operate and innovate. One such revolutionary development is the introduction of a state-of-the-art smelting machine that promises to redefine the smelting process. This groundbreaking innovation offers an array of benefits, ranging from improved efficiency and reduced energy consumption to minimal environmental impact. Here, we delve into the features and advantages of this cutting-edge smelting machine and its potential impact on the industrial sector.(Company Introduction):Leading the charge in technological breakthroughs, the renowned company {} has unveiled their latest creation, a next-generation smelting machine. With a long-standing reputation for excellence and innovation, {} has consistently driven the industry forward with their cutting-edge solutions. The introduction of this advanced smelting machine further solidifies their position as pioneers in industrial manufacturing.Impeccable Design and Operations:The newly developed smelting machine boasts an impeccable design that combines precision engineering with advanced automation. This fusion ensures enhanced performance levels while reducing the likelihood of errors. Built with industry-leading materials, the machine ensures durability and longevity, even under demanding operating conditions.Efficiency and Cost Reduction:By integrating the latest technological advancements, the smelting machine offers unmatched efficiency, leading to significant cost reductions for manufacturers. The machine optimizes the smelting process by minimizing resource wastage and maximizing output. Additionally, its intelligent monitoring system enables real-time analysis, allowing for swift identification of any inefficiencies or defects.Reduced Environmental Impact:Recognizing the pressing issue of environmental sustainability, {} has prioritized developing a smelting machine that aligns with eco-friendly practices. The advanced emissions control system incorporated into the machine helps minimize air pollution by filtering harmful substances. Furthermore, the machine's energy-efficient design reduces carbon emissions, contributing to a greener and more sustainable manufacturing process.Enhanced Safety Features:Safety is of utmost importance in modern industrial operations, and {} understands this well. The smelting machine comes equipped with a comprehensive range of safety features to ensure the well-being of workers and prevent accidents. The incorporation of state-of-the-art sensors and early-warning systems guarantee prompt response and risk mitigation, creating a secure work environment.Seamless Integration and Customization:Recognizing the diverse needs of different industries, {} has developed the smelting machine to seamlessly integrate with existing manufacturing processes. Whether it is in the steel, aluminum, or other metal industries, the machine's adaptability allows for easy incorporation and customization. This flexibility ensures minimal disruptions during installation and facilitates smooth operation tailored to specific production requirements.Benefits for Industrial Sector:The introduction of this groundbreaking smelting machine promises to revolutionize the industrial sector on multiple fronts. Manufacturers can experience increased production efficiency, reduced operational costs, and minimized energy consumption. Additionally, the improved environmental impact will contribute to sustainable manufacturing practices, thereby promoting a greener future for the industry.Market Outlook and Potential:With the increasing demand for efficient and sustainable manufacturing practices, the market potential for the {} smelting machine is vast. As more companies seek innovative solutions to improve their production processes, this cutting-edge technology offers a competitive advantage. Moreover, the positive environmental impact aligns perfectly with the growing global emphasis on reducing carbon footprints and adopting eco-friendly practices.Conclusion:The introduction of the state-of-the-art smelting machine by {} marks a significant milestone in the industrial manufacturing sector. Its impeccable design, efficiency, reduced environmental impact, and enhanced safety features position it as a game-changer in the industry. As manufacturers embrace this innovative technology, they can harness its benefits to optimize their operations, reduce costs, and contribute to a sustainable future. With the continued pursuit of excellence and innovation, {} remains at the forefront of transforming the industrial manufacturing landscape.

Discover the Advantages of Brass Induction Melting Furnaces in China

China Brass Induction Melting Furnace: Revolutionizing Furnace TechnologyChina Brass Induction Melting Furnace, the leading manufacturer of brass induction melting furnaces, has revolutionized furnace technology. Driven by a relentless pursuit of innovation, the company's state-of-the-art furnaces deliver unmatched performance and reliability, making them the top choice for metal processing firms across the globe.About China Brass Induction Melting FurnaceChina Brass Induction Melting Furnace was established in 1992. Since its inception, the company has focused on manufacturing high-quality induction melting furnaces for the metal processing industry. The company has a team of highly skilled engineers, technicians, and support staff who work tirelessly to deliver the best furnaces in the market.With over 27 years of experience in the industry, the company has established a reputation for excellence. It has over 300 employees and a production facility of over 20,000 square meters. The company's manufacturing processes adhere to strict quality control measures to ensure that each furnace that leaves its premises is of the highest quality.China Brass Induction Melting Furnace has over 7,000 successful installations in over 50 countries. The company's product range includes:- Brass induction melting furnaces- Gold induction melting furnaces- Silver induction melting furnaces- Copper induction melting furnaces- Aluminum induction melting furnaces- Vacuum induction melting furnaces- Induction heating furnacesEach furnace is designed to meet specific production needs and equipped with advanced features, such as high-efficiency energy-saving technology, automatic pouring, and temperature control systems.Features of China Brass Induction Melting FurnacesChina Brass Induction Melting Furnaces are designed with innovative features that make them stand out in the market. Here are some of the features that make them a top choice for metal processing firms:1. High-Quality MaterialsChina Brass Induction Melting Furnaces are made from high-quality materials that give them durability and longevity. The company uses top-grade insulation materials to ensure that the furnaces can withstand high temperatures and harsh operating conditions.2. Energy-Saving TechnologyChina Brass Induction Melting Furnaces are equipped with high-efficiency energy-saving technology. This technology reduces energy consumption, making the furnaces eco-friendly and cost-effective.3. Automatic Pouring SystemChina Brass Induction Melting Furnaces are equipped with an automatic pouring system that ensures that the molten metal is poured accurately and evenly. This feature saves time and reduces the risk of errors.4. Temperature Control SystemChina Brass Induction Melting Furnaces are equipped with a temperature control system that ensures that the furnaces maintain a constant temperature throughout the melting process. This feature improves the quality of the metal produced and reduces the risk of accidents.ConclusionChina Brass Induction Melting Furnace has set the benchmark for furnace technology. With a focus on innovation and quality, the company has become a top choice for metal processing firms across the globe. Its state-of-the-art furnaces deliver unmatched performance, reliability, and efficiency, making them an excellent investment for any metal processing business. In recent years, China Brass Induction Melting Furnace has established itself as a leader in the field of melting furnaces. The company's dedication to innovation and quality has enabled it to provide custom solutions for clients around the world. With a focus on sustainability and reducing energy consumption, China Brass Induction Melting Furnace is a company that demonstrates both vision and expertise. Whether you are in the market for brass, copper, silver, or another metal furnace, China Brass Induction Melting Furnace should be your top choice for high-quality, reliable equipment.

Steel Melting with Induction Furnace for Efficient Processes

Title: Revolutionary Induction Furnace Enhances Steel Melting ProcessIntroduction:With an unwavering commitment to innovation and excellence, a leading industrial equipment manufacturer presents a groundbreaking induction furnace designed specifically for steel melting. This cutting-edge furnace revolutionizes the steel industry with its advanced technology, optimized efficiency, and sustainability. Developed by the company's team of experts, this induction furnace promises to redefine steel melting processes, ensuring superior quality and productivity for manufacturers worldwide.Enhanced Steel Melting Process:The newly introduced induction furnace combines state-of-the-art technology with an array of features to optimize the steel melting process. By utilizing electromagnetic induction, this advanced furnace quickly and efficiently transforms raw materials into molten steel, eliminating the traditional reliance on fuel combustion.The furnace's electromagnetic field induces electric currents within the steel, resulting in rapid and uniform heating. This induction technology guarantees precise temperature control and homogeneous mixing, thus obviating the need for manual stirring or mixing agents. The elimination of these labor-intensive processes not only saves time and effort but also reduces overall production costs.Furthermore, the furnace's innovative design ensures minimal heat loss, increasing energy efficiency. The advanced insulation materials and optimized refractory lining retain heat effectively, minimizing energy consumption without compromising performance. This sustainable feature aligns with global efforts towards reducing carbon footprints, making it an eco-friendly choice for steel manufacturers.Unparalleled Performance and Customization:Equipped with cutting-edge control systems, the induction furnace offers unparalleled performance and flexibility. Manufacturers can easily adjust its parameters, such as power input and temperature, ensuring precise melting according to different steel grades and specific production requirements. The furnace's adaptable nature enables manufacturers to achieve consistent quality while accommodating changing market demands.Moreover, the furnace's user-friendly interface provides real-time monitoring and data analysis, optimizing operational efficiency. The integrated sensors and feedback mechanisms enable quick adjustments, minimizing downtime due to equipment failure and ensuring continuous production. This feature contributes to increased output, reduced production costs, and improved overall profit margins for steel manufacturers.Installation and Technical Support:In addition to providing a groundbreaking induction furnace, the company offers comprehensive installation assistance and technical support. Their team of experienced technicians ensures a smooth transition during the installation process, minimizing operational disruptions. Furthermore, the company provides professional training to operators, familiarizing them with the furnace's advanced features, safety protocols, and maintenance practices.Additionally, the company's dedicated technical support team is available 24/7 to address any queries or resolve technical issues promptly. This commitment to customer service ensures uninterrupted operations and maximizes the longevity of the induction furnace, preventing potential downtime and associated financial losses.Conclusion:With its revolutionary technology, optimized efficiency, and commitment to sustainability, the newly developed induction furnace presents a game-changing solution for the steel industry. By integrating advanced electromagnetic induction, precise temperature control, and superior energy efficiency, this furnace guarantees enhanced performance, reduced costs, and increased profitability for manufacturers worldwide.With comprehensive installation and technical support, the company aims to empower steel manufacturers, equipping them with cutting-edge technology and expertise. As the steel industry continues to evolve, this induction furnace sets a benchmark for innovation and paves the way for a more efficient, sustainable, and profitable future.

The Top Manufacturers of Brass Melting Furnaces Unveiled

In the world of manufacturing, brass is an essential material used in a wide range of applications. From plumbing fixtures and electrical components to musical instruments and decorative pieces, brass has proven to be a versatile and reliable material for centuries. However, the process of melting brass requires a great deal of precision and expertise. That’s where Brass Melting Furnace manufacturers come in.One of the leading manufacturers of Brass Melting Furnaces is a company that has been developing and producing high-quality melting solutions for over two decades. Their products are designed to meet the needs of a variety of casting processes, from high-pressure die casting to investment casting. Their brass melting furnaces are highly efficient and eco-friendly. They are built with state-of-the-art technology that ensures precision and control over the melting process. This means that manufacturers can achieve consistent quality and higher throughput, reducing material waste, and saving energy.One of the key features of their brass melting furnaces is their ability to work with a variety of alloys. Whether producers need to melt yellow brass, red brass, aluminum brass, or silicon brass, these furnaces can handle it all. This flexibility makes them a valuable addition to any manufacturing facility that works with brass.Another advantage of these furnaces is their ease of use. They are designed with operators in mind, making them easy to set up, monitor, and maintain. This reduces the amount of training required for operators and ensures that downtime is kept to a minimum.In addition to their high-quality melting furnaces, this company also offers a range of services to help their customers get the most out of their equipment. These services include technical support, training, and maintenance. They have a team of experts who can provide advice on casting processes and help customers optimize their furnace settings for maximum efficiency and quality.One thing that sets this company apart from its competitors is its commitment to sustainability. Their melting furnaces are designed with energy efficiency in mind, which reduces the amount of energy required to melt brass. This not only reduces greenhouse gas emissions but also saves manufacturers money on their energy bills. In addition to their eco-friendly designs, this company also follows sustainable manufacturing practices. They use materials that are responsibly sourced and recycled whenever possible. They also prioritize reducing waste and minimizing their environmental impact.Overall, Brass Melting Furnace manufacturers play a crucial role in the manufacturing industry by providing the equipment that allows for the precise and efficient melting of brass. With their advanced technology, expertise, and commitment to sustainability, this company’s brass melting furnaces are sure to continue to be a valuable asset to manufacturers around the world.

High-quality tilting crucible furnace for efficient metal melting

Tilting Crucible Furnace Revolutionizes Metal ProcessingMetal processing and manufacturing industries have seen a significant advancement in technology with the introduction of the Tilting Crucible Furnace. Developed by a leading company in the field of industrial equipment and machinery, this innovative furnace has been designed to enhance efficiency and precision in the melting and casting of various metals.The Tilting Crucible Furnace, which can accommodate a wide range of metals including aluminum, brass, and bronze, is equipped with state-of-the-art features that set it apart from traditional melting furnaces. One of its key attributes is its tilting function, which allows for easy pouring and casting of molten metal, thus reducing the risk of spillage and ensuring a smoother and more controlled process.In addition to its tilting capability, the furnace also boasts advanced temperature control technology, ensuring that the metal is heated to precise temperatures required for the specific melting and casting operations. This level of control not only improves the quality of the final product but also minimizes energy consumption, making the Tilting Crucible Furnace an environmentally friendly option for metal processing.The company behind this groundbreaking technology, a powerhouse in the industrial equipment and machinery sector, has a long-standing reputation for delivering high-quality and innovative solutions to its clients. With a team of experienced engineers and designers, the company is dedicated to pushing the boundaries of technology to meet the evolving needs of the industry."We are thrilled to introduce the Tilting Crucible Furnace to the market," said a spokesperson for the company. "We have invested significant time and resources into the research and development of this product, and we are confident that it will revolutionize the way metal processing is conducted. Our goal is to provide our clients with cutting-edge solutions that enhance efficiency and productivity, and the Tilting Crucible Furnace is a testament to that commitment."The Tilting Crucible Furnace is already generating buzz within the metal processing industry, with several companies expressing interest in adopting this new technology into their operations. Manufacturers and foundries are particularly keen on integrating the furnace into their facilities, as they recognize the potential for improved productivity and cost savings."We have been closely following the development of the Tilting Crucible Furnace, and we believe it has the potential to make a significant impact on our metal processing operations," said a representative from a large manufacturing company. "The ability to tilt the furnace for pouring and casting is a game-changer for us, and we are excited about the prospect of integrating this technology into our production line."In addition to its benefits for large-scale industrial operations, the Tilting Crucible Furnace is also gaining attention from smaller-scale metal fabricators and artisans. The furnace's versatility and precision make it an attractive option for those working on custom metal products and intricate designs, as it offers greater control and consistency in the casting process.As the company continues to promote the Tilting Crucible Furnace and expand its reach to potential clients, it is also exploring further advancements and enhancements to the technology. By staying at the forefront of innovation, the company aims to solidify its position as a leader in providing cutting-edge solutions for the metal processing and manufacturing industries.With the introduction of the Tilting Crucible Furnace, the company has set a new standard for efficiency, precision, and sustainability in metal processing. As more companies recognize the value of this innovative technology, it is poised to reshape the way metals are melted, cast, and fabricated, paving the way for a more advanced and dynamic future in the industry.