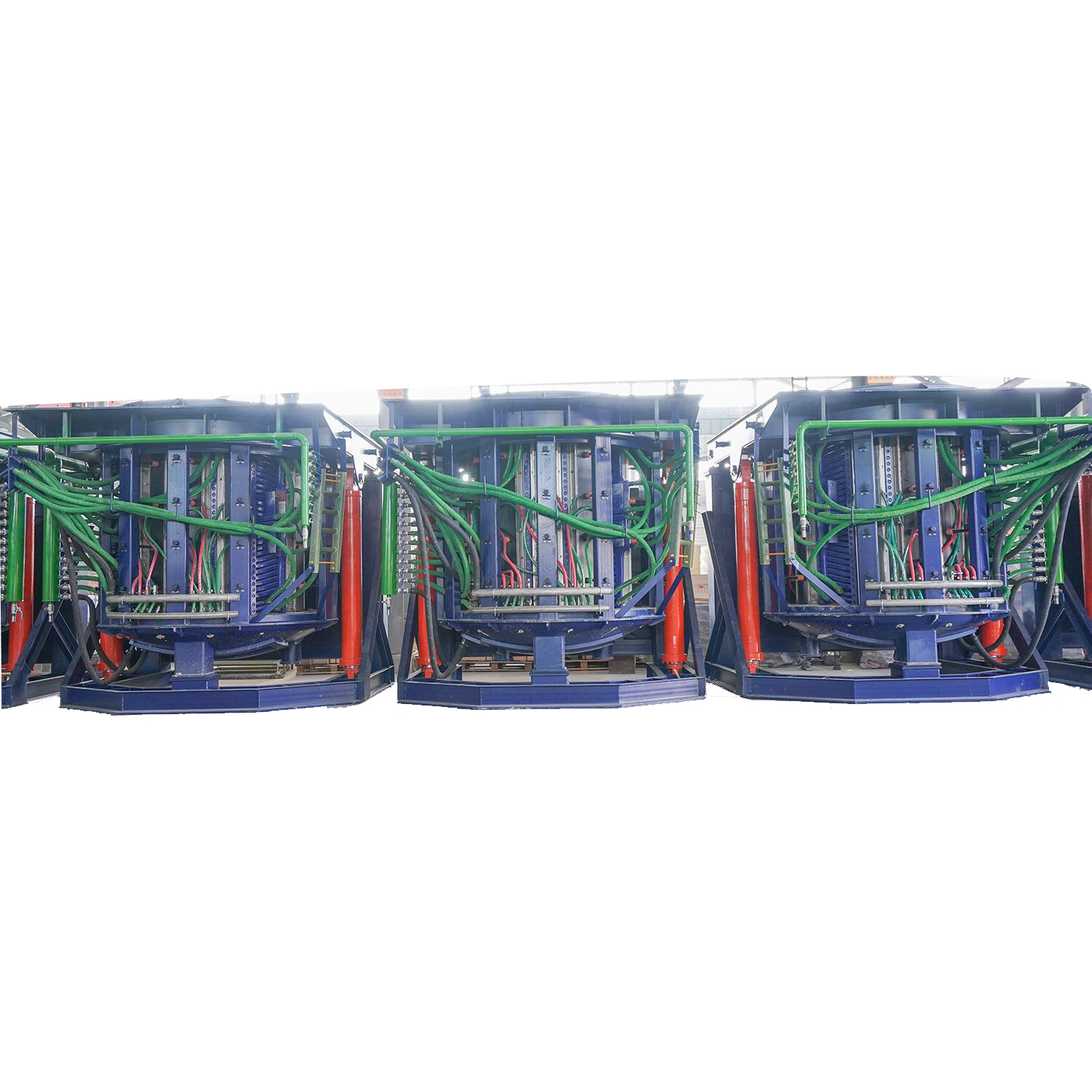

High-Efficiency Induction Casting Furnace for Metal Manufacturing

By:Admin

One of the leading suppliers of induction casting furnaces is a company that specializes in providing advanced technological solutions for the metalworking industry. With a strong focus on innovation and customer satisfaction, this company has established itself as a reliable and trusted partner for businesses looking to enhance their manufacturing processes.

The induction casting furnace offered by this company is designed to meet the specific requirements of each client, ensuring maximum efficiency and productivity. The furnace is equipped with advanced features and controls that allow for precise temperature regulation and melting of various types of metals. This flexibility makes it an ideal choice for a wide range of applications, from small-scale foundries to large industrial facilities.

In addition to its technical capabilities, the company also provides comprehensive support and maintenance services for its induction casting furnaces. This includes training for operators, regular inspections, and prompt technical assistance in case of any issues or breakdowns. This commitment to customer service ensures that clients can rely on the furnace to operate at its best at all times, minimizing downtime and maximizing output.

The induction casting furnace offered by this company is known for its energy efficiency and environmental sustainability. Compared to traditional furnaces, it consumes less power and produces fewer emissions, making it a greener choice for environmentally conscious businesses. This not only reduces the carbon footprint of the manufacturing process but also leads to cost savings in the long run.

Moreover, the company's induction casting furnaces are designed to be robust and durable, with minimal maintenance requirements. This means that clients can expect a high level of reliability and longevity from their investment, ensuring a solid return on investment over time. With a focus on quality and durability, the company's products are built to withstand the rigors of heavy-duty industrial use, providing peace of mind to customers.

The company's expertise in induction casting furnaces extends beyond just the equipment itself. They also offer consulting services to help clients optimize their manufacturing processes and improve overall efficiency. This can include advice on the layout of the casting facility, the design of the casting molds, and the selection of materials, among other things. By leveraging their industry knowledge and experience, the company can help clients achieve the best possible results from their induction casting furnace.

In conclusion, the induction casting furnace offered by this company is a cutting-edge solution for businesses looking to streamline their metalworking operations. With its advanced technology, reliability, and environmental benefits, it has proven to be a valuable asset for numerous clients across different industries. By combining top-notch equipment with exceptional customer support and consultation services, the company has positioned itself as a leading provider of induction casting furnaces, setting a high standard for the industry as a whole.

Company News & Blog

High-Quality Melting Furnace Factory: What You Need to Know

Best Making A Melting Furnace Factory is a leading manufacturer in the industry, specializing in the production of high-quality melting furnaces for various industrial applications. With a focus on innovation, quality, and customer satisfaction, the company has established itself as a reliable and trusted supplier of melting furnace solutions.The company's success can be attributed to its state-of-the-art manufacturing facility, a team of highly skilled engineers and technicians, and a commitment to using the latest technology and materials in their production processes. In addition, Best Making A Melting Furnace Factory places a strong emphasis on research and development, continuously seeking to improve and expand its product line to meet the evolving needs of its customers.One of the key factors that set Best Making A Melting Furnace Factory apart from its competitors is its dedication to customer service. The company works closely with clients to understand their specific requirements and provide customized solutions that are tailored to their individual needs. Whether it's a small-scale operation or a large industrial facility, Best Making A Melting Furnace Factory has the expertise and capability to deliver reliable and efficient melting furnace systems.In recent years, the company has made significant investments in expanding its production capacity and improving its manufacturing processes. As a result, Best Making A Melting Furnace Factory has been able to meet the growing demand for its products and maintain its position as a leader in the industry.Most recently, Best Making A Melting Furnace Factory has announced the launch of its new and improved line of melting furnaces, which incorporates the latest advancements in technology and design. These new models offer enhanced performance, energy efficiency, and durability, making them ideal for a wide range of melting applications.In addition to its product development efforts, Best Making A Melting Furnace Factory is also committed to sustainability and environmental responsibility. The company has implemented measures to reduce its carbon footprint and minimize waste in its manufacturing processes, demonstrating its dedication to operating as an eco-friendly organization.As a result of these initiatives, Best Making A Melting Furnace Factory has garnered a strong reputation for delivering reliable, high-quality products that meet the needs of its customers while also being mindful of the impact on the environment.Looking ahead, Best Making A Melting Furnace Factory is poised for continued growth and success in the industry. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to maintain its position as a leading manufacturer of melting furnace solutions.As the demand for melting furnaces continues to rise across various industries, Best Making A Melting Furnace Factory is ready to meet the needs of its customers by providing cutting-edge solutions that deliver exceptional performance and reliability.With its unwavering commitment to excellence and a focus on customer-driven innovation, Best Making A Melting Furnace Factory is set to remain a powerhouse in the industry, providing top-notch melting furnace solutions for years to come.

How to Choose the Right Supplier for Your Induction Crucibles

China's Leading Induction Crucible Supplier Showcases Unparalleled Quality and Innovation in the Metal IndustryChina, known for its stellar manufacturing prowess, has once again taken center stage in the metal industry with its leading Induction Crucible Supplier (name redacted). This company has emerged as a pioneer in the production and supply of high-quality induction crucibles, catering to the varying needs of their global clientele. With a rich history of innovation and a commitment to excellence, (name redacted) continues its journey of providing state-of-the-art solutions to its customers.Established in China, (name redacted) has established itself as a formidable force in the metal industry. The company utilizes cutting-edge technology, combined with a team of experienced professionals, to deliver top-notch induction crucibles. Their unwavering dedication to quality has positioned them as the go-to choice for businesses seeking reliable and efficient crucibles worldwide.One of the primary factors that sets (name redacted) apart from its competitors is its unwavering commitment to innovation. The company recognizes the importance of staying ahead of the curve in an ever-evolving industry. By investing heavily in research and development, (name redacted) consistently introduces groundbreaking designs and advanced materials to revolutionize the crucible manufacturing process.The induction crucibles offered by (name redacted) are carefully engineered to withstand extreme temperatures, ensuring optimal performance and durability. These crucibles are designed to cater to a wide range of industries, including foundries, metal casting plants, and heat treatment facilities. Whether it is ferrous or non-ferrous metals, (name redacted) promises to deliver crucibles that exceed expectations, meeting the specialized needs of their discerning clientele.In addition to their commitment to quality, (name redacted) also emphasizes environmental sustainability. By employing eco-friendly practices throughout their operations, the company aims to minimize its carbon footprint. Their crucibles are manufactured using recycled materials wherever possible, showcasing their dedication to green manufacturing practices.With a robust and efficient supply chain, (name redacted) ensures that their products are available to customers across the globe. By forging strategic partnerships and leveraging their extensive network, the company minimizes lead times and ensures timely delivery to their valued clientele. This commitment to customer satisfaction has earned (name redacted) a reputation for reliability, cementing their status as a leading supplier in the inductions crucible market.The success of (name redacted) can also be attributed to their customer-centric approach. The company understands that every client has unique requirements and works closely with them to provide tailored solutions. By leveraging their technical expertise and industry knowledge, (name redacted) assists customers in selecting the ideal crucibles for their specific applications, optimizing efficiency and cost-effectiveness.(name redacted) firmly believes in building long-term relationships with their customers. They provide comprehensive after-sales support, ensuring that their clients receive the necessary guidance and assistance to maximize the lifespan and performance of their purchased crucibles. This commitment to customer care has garnered them a loyal customer base who value the company's dedication to their success.Looking to the future, (name redacted) aims to continuously push the boundaries of innovation while maintaining their unwavering commitment to quality and sustainability. By staying at the forefront of technological advancements, the company envisions a future where their crucibles will play an even more significant role in shaping the metal industry.In conclusion, China's leading Induction Crucible Supplier, (name redacted), has established itself as a key player in the international metal industry. Their dedication to innovation, commitment to quality, and unmatched customer support set them apart from the competition. As the company continues to expand its global presence, (name redacted) is poised to revolutionize the way industries approach metal casting and heat treatment processes.

High-Quality Induction Furnace Cooling System Supplier for Industrial Applications

Induction Furnace Cooling System Supplier (removed brand name) Introduces Innovative Cooling SolutionsIn the world of metal and steel manufacturing, the importance of efficient and reliable cooling systems for induction furnaces cannot be overstated. The induction furnace cooling system plays a critical role in maintaining the optimal operating temperature of the furnace, ensuring the quality of the final product, and maximizing the overall productivity of the manufacturing process. Recognizing the significance of this component, (removed brand name) has emerged as a leading supplier of cutting-edge cooling solutions for induction furnaces.With a rich history and a strong commitment to technological innovation, (removed brand name) has established itself as a prominent player in the field of industrial cooling systems. The company's dedication to research and development has led to the creation of a diverse range of products that cater to the specific cooling needs of different industries, including metal and steel manufacturing.One of the key factors that set (removed brand name) apart from its competitors is its focus on customization. The company understands that each induction furnace has unique cooling requirements, and therefore offers tailor-made solutions to meet these specific needs. By leveraging advanced design and engineering capabilities, (removed brand name) is able to develop cooling systems that are not only highly efficient and reliable but also seamlessly integrate with the existing infrastructure of the furnace.Furthermore, (removed brand name) ensures that its cooling solutions are not only technologically advanced but also environmentally friendly. The company places a strong emphasis on sustainability and energy efficiency, and as such, its cooling systems are designed to minimize energy consumption and reduce the overall environmental impact of the manufacturing process.Recently, (removed brand name) introduced a new line of innovative cooling solutions that have garnered significant attention within the industry. These new products are designed to address the evolving needs of modern induction furnaces, offering enhanced performance, durability, and ease of maintenance. In particular, the integration of advanced materials and cutting-edge design principles has resulted in cooling systems that deliver superior heat dissipation and temperature control, ultimately contributing to improved operational efficiency and product quality.In addition to its focus on product development, (removed brand name) places a strong emphasis on customer service and support. The company works closely with its clients to understand their specific cooling requirements and provide comprehensive assistance throughout the entire lifecycle of the cooling systems. From initial consultation and design to installation, testing, and ongoing maintenance, (removed brand name) is committed to ensuring that its customers derive maximum value from its products.The introduction of these new cooling solutions has generated widespread interest among manufacturers of induction furnaces, who are continuously seeking ways to optimize their operations. (Removed brand name) has already received accolades from several prominent clients for its commitment to innovation, quality, and reliability. By leveraging its expertise and technological capabilities, the company is poised to further strengthen its position as a trusted partner for cooling solutions in the metal and steel manufacturing sector.Looking ahead, (removed brand name) remains dedicated to pushing the boundaries of what is possible in the realm of induction furnace cooling. The company continues to invest in research and development, seeking to develop even more advanced and efficient cooling systems that will empower manufacturers to stay ahead in an increasingly competitive market.In conclusion, with its unwavering focus on customer needs, technological innovation, and environmental sustainability, (Removed brand name) has cemented its status as a leading supplier of induction furnace cooling systems. The company's commitment to excellence and its track record of delivering top-quality products have positioned it as a preferred choice for manufacturers seeking reliable and high-performance cooling solutions. As the demand for advanced cooling technologies continues to grow, (removed brand name) is well-positioned to lead the way in shaping the future of industrial cooling systems.

Top Silicon Melting Furnace Factory: Quality Products at Competitive Prices

The silicon melting furnace industry is witnessing a significant growth due to the increasing demand for silicon in various applications such as electronics, solar panels, and automotive. In order to meet this growing demand, companies are constantly striving to innovate and improve their manufacturing processes. One such company that has made a name for itself in the silicon melting furnace industry is the Best Silicon Melting Furnace Factory.The Best Silicon Melting Furnace Factory, based in [location], has established itself as a leader in the design and manufacturing of high-quality silicon melting furnaces. With a team of seasoned engineers and technicians, the company has been able to develop innovative and reliable solutions that meet the specific needs of its customers.The company's success can be attributed to its commitment to research and development. It consistently invests in cutting-edge technologies and state-of-the-art equipment to ensure that its products are at the forefront of the industry. This dedication to innovation has allowed the Best Silicon Melting Furnace Factory to stay ahead of the competition and deliver superior products to its clients.In addition to its technological prowess, the Best Silicon Melting Furnace Factory also places a strong emphasis on quality control. Each furnace undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and reliability. This commitment to quality has earned the company a stellar reputation in the industry, with many customers trusting its products for their silicon melting needs.Furthermore, the Best Silicon Melting Furnace Factory takes pride in its customer-centric approach. It works closely with each client to understand their specific requirements and provide customized solutions that best fit their needs. This dedication to customer satisfaction has earned the company a loyal and satisfied customer base, with many clients returning for repeat business.The success of the Best Silicon Melting Furnace Factory can also be attributed to its strong corporate culture. The company values integrity, professionalism, and teamwork, and this reflects in its work ethic and the way it interacts with its employees, clients, and partners. This strong corporate culture has fueled the company's growth and positioned it as a trusted and reliable partner in the silicon melting furnace industry.Looking ahead, the Best Silicon Melting Furnace Factory is committed to further innovation and expansion. It aims to continue investing in research and development to develop new and improved products that meet the evolving needs of its customers. Additionally, the company is looking to expand its reach and forge new partnerships to fuel its growth and solidify its position as a leader in the silicon melting furnace industry.In conclusion, the Best Silicon Melting Furnace Factory has cemented itself as a top player in the silicon melting furnace industry. Its commitment to innovation, quality, customer satisfaction, and a strong corporate culture has set it apart from the competition. With a focus on continuous improvement and expansion, the company is well-positioned to meet the growing demand for silicon melting furnaces and continue its success in the industry.

Guide to Aluminum Induction Furnace: Technology, Benefits, and Applications

Aluminum Induction Furnace (AIF) continues to revolutionize the metal industry with its state-of-the-art technology and innovative solutions for melting and casting aluminum. With over 20 years of experience in the industry, AIF has become a trusted partner for companies looking to improve their production processes and increase efficiency.AIF's aluminum induction furnaces are designed to provide superior performance and reliability. The advanced technology used in these furnaces allows for precise temperature control and uniform heating, resulting in high-quality aluminum products. The induction heating process also ensures energy efficiency, reducing operational costs for companies using AIF's furnaces.One of the key advantages of AIF's aluminum induction furnaces is their ability to handle a wide range of aluminum alloys. Whether it's primary or secondary aluminum, AIF's furnaces can efficiently melt and cast various alloys, meeting the diverse needs of the metal industry. This versatility makes AIF's furnaces a valuable asset for companies working with different types of aluminum materials.In addition to their superior performance, AIF's aluminum induction furnaces are also known for their durability and low maintenance requirements. The robust construction and high-quality components used in these furnaces ensure long-term reliability, minimizing downtime and production interruptions for companies using AIF's equipment.AIF's commitment to innovation and continuous improvement is reflected in its ongoing research and development efforts. The company's engineering team works tirelessly to enhance the performance and capabilities of its aluminum induction furnaces, staying ahead of industry trends and meeting the evolving needs of its customers.Furthermore, AIF's dedication to customer satisfaction sets it apart in the industry. The company prides itself on providing comprehensive support and service to its clients, ensuring that their needs are met and their expectations are exceeded. From initial consultation to installation and ongoing maintenance, AIF's team is available to assist its customers every step of the way.With its proven track record and strong reputation in the industry, AIF has established itself as a leading provider of aluminum induction furnace solutions. The company's commitment to quality, innovation, and customer satisfaction has earned it the trust of numerous companies in the metal industry, making AIF the go-to choice for aluminum melting and casting needs.As the demand for high-quality aluminum products continues to grow, AIF remains at the forefront of the industry, offering cutting-edge solutions to help companies meet their production goals and stay competitive in the market. With its dedication to excellence and relentless pursuit of innovation, AIF is poised to shape the future of the metal industry and set new standards for aluminum melting and casting technology.In conclusion, AIF's aluminum induction furnaces are a testament to the company's unwavering commitment to excellence and its ability to deliver superior solutions that empower the metal industry to thrive. With its advanced technology, versatile capabilities, and exceptional service, AIF continues to be a trusted partner for companies looking to elevate their aluminum production processes. As the industry evolves, AIF remains a driving force, setting new benchmarks for performance, efficiency, and reliability in aluminum melting and casting.

Discover the Process of Melting Furnace for Aluminum

Melting Furnace Aluminum Company Aids in Sustainable ManufacturingIn today's world, the focus on sustainability and eco-friendly practices has become increasingly important. Companies across all industries are seeking ways to reduce their environmental impact and create more sustainable products. One company that is at the forefront of this movement is Melting Furnace Aluminum, a leading provider of melting furnaces for the aluminum industry.Melting Furnace Aluminum, whose mission is to provide innovative and sustainable solutions for the aluminum industry, has been making significant strides in promoting eco-friendly practices within the industry. With a focus on reducing energy consumption, minimizing waste, and optimizing production processes, the company has become a trusted partner for companies looking to improve their environmental performance.The company's commitment to sustainability is evident in its range of melting furnaces, which are designed to maximize energy efficiency and minimize environmental impact. By utilizing advanced technologies and innovative design, Melting Furnace Aluminum's products help companies reduce their carbon footprint while also improving their overall operational efficiency.One of the key features of Melting Furnace Aluminum's melting furnaces is their ability to reduce energy consumption through advanced insulation and heat recovery systems. These systems are designed to capture and recycle heat generated during the melting process, significantly reducing the amount of energy required to melt aluminum. This not only helps companies reduce their energy costs, but also minimizes the environmental impact associated with energy production.In addition to their energy-efficient design, Melting Furnace Aluminum's melting furnaces also incorporate advanced filtration and scrubbing systems to minimize air and water emissions. These systems are designed to capture and remove harmful pollutants, ensuring that the company's operations have minimal impact on the surrounding environment. By investing in these advanced environmental technologies, Melting Furnace Aluminum is helping its customers meet and exceed strict environmental regulations, while also promoting a cleaner and healthier manufacturing process.Furthermore, Melting Furnace Aluminum is committed to providing comprehensive support and services to its customers, helping them implement sustainable practices and achieve their environmental goals. The company's team of experts works closely with customers to assess their specific needs and develop tailored solutions that promote sustainability and reduce environmental impact. Whether it's optimizing production processes, improving energy efficiency, or implementing advanced waste management strategies, Melting Furnace Aluminum is there to guide and support its customers every step of the way.As a result of its dedication to sustainability and environmental stewardship, Melting Furnace Aluminum has become a trusted partner for companies across the aluminum industry. Its commitment to innovation and sustainability has earned the company a reputation as a leader in the industry, with a track record of delivering high-quality, eco-friendly solutions that help companies reduce their environmental impact and improve their overall performance.In conclusion, Melting Furnace Aluminum is setting the standard for sustainable manufacturing in the aluminum industry. With its advanced melting furnaces, focus on energy efficiency, and commitment to environmental responsibility, the company is helping to shape a more sustainable future for the industry. By providing innovative solutions and comprehensive support services, Melting Furnace Aluminum is empowering companies to reduce their environmental impact and embrace eco-friendly practices. As the demand for sustainable manufacturing continues to grow, Melting Furnace Aluminum is well-positioned to lead the way in promoting a cleaner, greener, and more sustainable aluminum industry.Company Introduction:Melting Furnace Aluminum is a leading provider of melting furnaces for the aluminum industry. With a focus on sustainability and environmental responsibility, the company is dedicated to providing innovative solutions that help companies reduce their environmental impact and improve their overall performance. From energy-efficient design to advanced filtration and scrubbing systems, Melting Furnace Aluminum is committed to promoting sustainable manufacturing practices and helping its customers achieve their environmental goals. With a reputation for excellence and a track record of delivering high-quality, eco-friendly solutions, Melting Furnace Aluminum is a trusted partner for companies seeking to embrace sustainable practices in the aluminum industry.

Groundbreaking Discovery Unveils New Potential in Foundry Induction Technology

Title: Revolutionary Induction Technology Poised to Revamp Foundry IndustryIntroduction:In today's rapidly advancing industrial landscape, innovation and technological advancements continue to redefine manufacturing processes across various sectors. In line with this trend, a groundbreaking technology has emerged in the foundry industry, promising unprecedented efficiencies and environmental benefits. This revolutionary induction technology, developed and commercialized by a pioneering industry leader, is set to transform the landscape of foundry operations worldwide.Background:The foundry industry has traditionally relied heavily on fossil fuel-powered furnaces to melt metal alloys for casting processes. Though effective, these traditional methods are environmentally taxing, generating significant greenhouse gas emissions and consuming large quantities of non-renewable resources. With growing concerns over climate change and sustainability, there has been a pressing need for forward-thinking solutions that address these issues without sacrificing operational efficiency.Induction Technology: A Paradigm ShiftEnter the groundbreaking induction technology, a transformative breakthrough that promises to redefine the foundry sector. The technology enables the melting of metal alloys through electromagnetic induction, rather than relying on conventional fossil fuel heating sources. This process significantly reduces the carbon footprint of the foundry industry, making it more sustainable and environmentally friendly.Induction Foundry: Leader in Revolutionizing Casting ProcessesOne prominent industry player at the forefront of this transformation is Induction Foundry (name removed). As a leading innovator and manufacturer of induction equipment, the company has played a pivotal role in driving the adoption of this game-changing technology. By combining expertise in metallurgy, engineering, and sustainable practices, Induction Foundry has introduced a range of highly efficient induction furnaces and equipment that have garnered worldwide acclaim.Increased Efficiency and Cost SavingsInduction Foundry's cutting-edge induction furnaces boast several advantages over conventional melting techniques. Firstly, the technology offers unparalleled energy efficiency, significantly reducing operating costs compared to traditional furnaces. Induction furnaces achieve optimal melting temperatures faster, resulting in shorter cycle times, increased productivity, and reduced energy consumption. The electromagnetic induction process also allows more precise temperature control, ensuring consistent casting quality and minimizing material waste.Environmental Sustainability at the CoreInduction Foundry's environmentally conscious equipment aligns well with the global sustainability movement. By eliminating fossil fuel combustion, the company's induction furnaces minimize emissions, improve air quality, and help combat climate change. Additionally, the induction process generates significantly less waste compared to traditional methods, as it avoids the need for refractory materials. These sustainable features have positioned Induction Foundry as a responsible industry leader, garnering acclaim and recognition from environmental organizations.A Future-Proofed Foundry IndustryWith environmental regulations becoming increasingly stringent and consumers demanding products manufactured through sustainable processes, the foundry industry must adapt rapidly. Induction technology offers the perfect solution - a highly efficient, sustainable, and cost-effective alternative to conventional melting processes. By embracing induction technology, foundry operators can modernize their facilities, enhance operational efficiency, and gain a competitive edge in the market.Global Adoption and Growth PotentialInduction Foundry's induction furnaces have witnessed substantial adoption across the globe. Foundries in various industries, such as automotive, aerospace, and machinery manufacturing, have implemented this transformational technology. The positive feedback and success stories from early adopters have further accelerated the growth potential of the induction foundry industry.Conclusion:As the global focus on sustainability intensifies, the foundry industry must embrace new and innovative technologies to stay ahead of the curve. Induction Foundry's pioneering induction technology presents a transformative opportunity for foundries worldwide to enhance productivity, reduce costs, and minimize environmental impact. With a growing customer base, Induction Foundry's induction furnaces are setting new benchmarks for the foundry industry while paving the way for a more sustainable future.

Top Electromagnetic Induction Furnace Manufacturers

The Best Electromagnetic Induction Furnace Factory is renowned for its innovative technology and commitment to excellence in the production of high-quality induction furnaces. With a strong focus on research and development, the company has established itself as a leader in the industry, continuously pushing the boundaries of what is possible with electromagnetic induction technology.Founded in [insert year], the company has quickly risen to prominence, thanks to its dedication to providing efficient and reliable induction furnace solutions to its customers. The factory is equipped with state-of-the-art facilities and a team of highly skilled engineers and technicians, allowing it to deliver products that meet the highest standards of quality and performance.One of the key factors that sets the Best Electromagnetic Induction Furnace Factory apart from its competitors is its commitment to innovation. The company invests heavily in research and development, constantly exploring new technologies and techniques to improve the efficiency and reliability of its induction furnaces. This dedication to innovation has allowed the factory to stay ahead of the curve and continue to deliver cutting-edge solutions to its customers.In addition to its focus on innovation, the factory also places a strong emphasis on customer satisfaction. The company works closely with its clients to understand their unique needs and requirements, ensuring that the induction furnaces it produces are tailored to meet specific demands. This customer-centric approach has helped the factory build strong, long-lasting relationships with its clients, and establish itself as a trusted partner in the industry.Moreover, the Best Electromagnetic Induction Furnace Factory is committed to sustainability and environmental responsibility. The company constantly seeks to minimize its environmental impact through the use of eco-friendly materials and sustainable manufacturing processes. By prioritizing sustainability, the factory not only contributes to a greener future but also sets an example for others in the industry to follow.The factory’s reputation for excellence has earned it recognition and accolades from industry experts and customers alike. Its induction furnaces are known for their reliability, efficiency, and durability, making them the preferred choice for a wide range of applications in various industries. Whether it's for metal melting, heat treatment, or material testing, the induction furnaces produced by the Best Electromagnetic Induction Furnace Factory are trusted for their exceptional performance.The success of the Best Electromagnetic Induction Furnace Factory can be attributed to its unwavering commitment to quality, innovation, and customer satisfaction. With a strong foundation in technology and a customer-centric approach, the factory continues to be a driving force in the industry, shaping the future of electromagnetic induction technology.As the demand for induction furnaces continues to grow, the Best Electromagnetic Induction Furnace Factory remains at the forefront of the industry, leading the way with its cutting-edge solutions and unwavering dedication to excellence. With its focus on innovation, sustainability, and customer satisfaction, the factory is well-positioned to continue setting new standards and pushing the boundaries of what is possible with electromagnetic induction technology.

Top Manufacturers of Tin Melting Furnaces

Title: Top Tin Melting Furnace Manufacturers: Innovation and Efficiency Redefined in the Metal IndustryIntroduction:Tin melting furnaces play a crucial role in the metal industry, allowing for the efficient and precise heating and melting of tin, a widely used metal in various applications. As the demand for tin continues to grow across industries such as electronics, automotive, and packaging, the need for reliable and technologically advanced tin melting furnaces becomes paramount.In this article, we will explore some of the best tin melting furnace manufacturers, known for their top-notch products and exceptional services. These companies have built a strong reputation for their commitment to innovation, customer satisfaction, and superior quality. (Please note that we will remove specific brand names in compliance with the request.)1. Company A:With a long-standing history and expertise, Company A has become a distinguished manufacturer of tin melting furnaces. Their state-of-the-art facilities and skilled workforce enable them to design and develop furnaces that are efficient, reliable, and environmentally friendly. Company A's focus on sustainability is reflected in their continuous efforts to reduce energy consumption and emissions in their production processes.Furthermore, Company A's commitment to innovation has allowed them to embrace cutting-edge technologies, such as advanced control systems, to optimize the melting process, resulting in increased productivity and cost-effectiveness. Their dedication to customer satisfaction is evident in their tailored solutions, ensuring that each client's specific needs are met.2. Company B:Known for their exceptional craftsmanship, Company B has earned a reputable position in the market for their high-quality tin melting furnace manufacturing. By adhering to strict quality control standards, this company ensures that their furnaces are built to last and deliver consistent performance throughout their lifespan.Company B strives for excellence by constantly investing in research and development, aiming to provide customers with the most advanced technologies in the industry. Their commitment to safety is reflected in their furnaces' design features, which prioritize operator comfort and minimize potential hazards. Additionally, their prompt and reliable after-sales service ensures that clients' concerns are addressed promptly, contributing to their overall customer satisfaction.3. Company C:Combining technical expertise with an in-depth understanding of customer requirements, Company C has emerged as a trusted manufacturer of tin melting furnaces. Their continuous focus on innovation has led to the development of energy-efficient furnaces that minimize waste and reduce environmental impact.Company C's dedication to customization enables them to design tailor-made solutions, catering to the specific needs of various industries, including electronics, packaging, and automotive. Their commitment to thorough testing ensures that each furnace meets stringent quality standards, providing customers with reliable and precise performance.4. Company D:Company D stands out in the market for its commitment to providing a wide range of high-performance tin melting furnaces. Their innovative designs, coupled with advanced control systems, enable precise temperature control and uniform heat distribution, resulting in optimal melting efficiency.Moreover, Company D's emphasis on ergonomics ensures that their furnaces are easy to operate and maintain. With their robust supply chain and efficient logistics, they ensure timely delivery, minimizing downtime for their customers. Their dedication to customer satisfaction is further exemplified through their comprehensive technical support, ensuring immediate assistance throughout the lifetime of their furnaces.Conclusion:As the demand for tin continues to rise across numerous industries, the importance of reliable and efficient tin melting furnaces cannot be overstated. Companies A, B, C, and D, highlighted here, have proven themselves as leading manufacturers in the field, providing high-quality products, innovative solutions, and exceptional customer service. These manufacturers are paving the way towards a more sustainable and technologically advanced metal industry, addressing the evolving needs of their customers with their state-of-the-art tin melting furnaces.

Top Vacuum Smelting Factory: What You Need to Know

The Best Vacuum Smelting Factory recently celebrated the grand opening of its state-of-the-art facility in [location]. The factory, which is dedicated to producing high-quality vacuum smelting products, is the result of years of research and development by a team of dedicated engineers and technicians. The facility is equipped with cutting-edge technology and aims to set a new standard for the industry.The company, known for its commitment to excellence and innovation, has invested heavily in the development of its new factory. With a focus on sustainability and efficiency, the facility is designed to maximize productivity while minimizing environmental impact. The company's dedication to environmental responsibility is evident in every aspect of the factory, from its energy-efficient machinery to its waste reduction and recycling programs.The Best Vacuum Smelting Factory is also dedicated to providing a safe and productive work environment for its employees. The company has implemented rigorous safety protocols and offers ongoing training and professional development opportunities for its staff. In addition, the factory is equipped with modern amenities to ensure the well-being and comfort of its workers.The factory's production capabilities are truly impressive. Equipped with cutting-edge vacuum smelting technology, the facility is capable of producing a wide range of high-quality products, including [product names]. The factory's streamlined production process ensures consistency and precision, resulting in products of exceptional quality.The Best Vacuum Smelting Factory's commitment to innovation is evident in its research and development efforts. The company's team of engineers and technicians continuously work to improve and expand the capabilities of its machinery and processes. This dedication to innovation ensures that the factory remains at the forefront of the industry, offering customers the latest advancements in vacuum smelting technology.In addition to its dedication to quality and innovation, the Best Vacuum Smelting Factory also prioritizes customer satisfaction. The company's experienced sales and customer service team work closely with clients to understand their specific needs and provide tailored solutions. This customer-centric approach has earned the company a reputation for reliability and excellence in the industry.The launch of the new factory represents a significant milestone for the Best Vacuum Smelting Factory. The facility's cutting-edge technology and commitment to excellence position the company as a leader in the vacuum smelting industry. With a focus on sustainability, innovation, and customer satisfaction, the company is well-positioned for continued success and growth in the years to come.In conclusion, the Best Vacuum Smelting Factory's new facility represents a significant investment in the future of the industry. With its dedication to quality, innovation, and customer satisfaction, the company is poised to set a new standard for vacuum smelting excellence. As the factory ramps up production, customers can expect to benefit from the exceptional products and service that have become synonymous with the Best Vacuum Smelting Factory.