High-Quality Electric Furnace Factory for Melting Aluminum

By:Admin

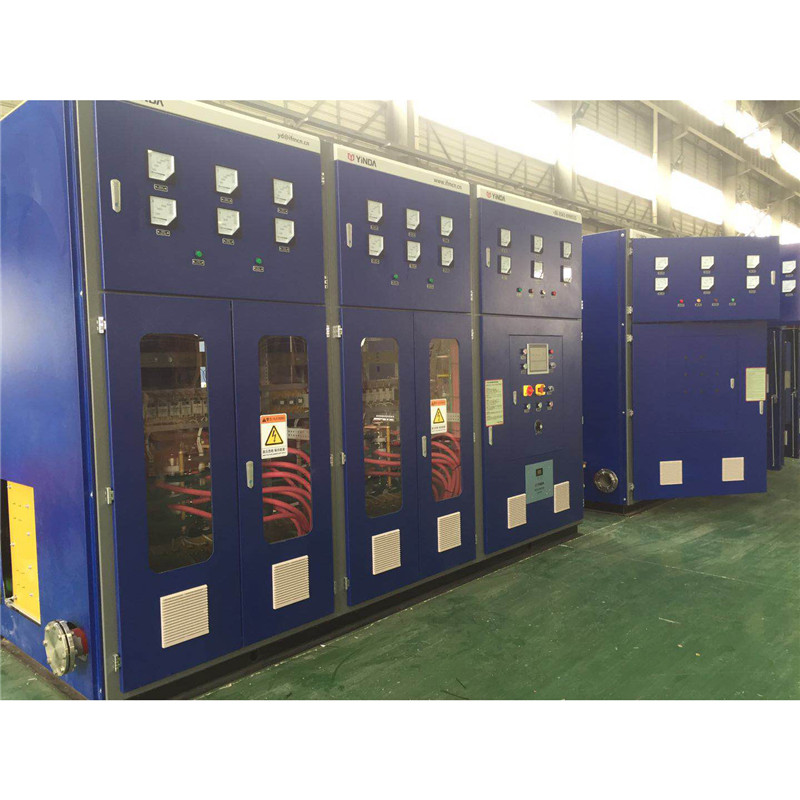

[City, Date] - Best Melting Aluminum Electric Furnace Factory has recently been recognized as a top manufacturer in the industry. The company's commitment to quality and innovation has set them apart as a leading provider of electric furnaces for melting aluminum and other metals.

The factory, located in [City], has been in operation for over 20 years and has garnered a reputation for producing high-quality, reliable electric furnaces. Their success can be attributed to a combination of advanced technology, skilled craftsmanship, and a dedication to meeting the needs of their customers.

With a focus on continuous improvement and innovation, Best Melting Aluminum Electric Furnace Factory has developed a comprehensive range of electric furnaces designed specifically for melting aluminum. Their product line includes various models with different capacities and features, catering to the diverse needs of their clients.

In addition to their standard product offerings, the factory also provides customized solutions to meet specific requirements. This flexibility has allowed them to establish themselves as a trusted partner for businesses in various industries, including automotive, aerospace, and manufacturing.

The company's commitment to quality is evident in the materials used and the attention to detail in the manufacturing process. By utilizing high-grade components and advanced manufacturing techniques, they ensure that their electric furnaces are built to last and perform consistently under demanding conditions.

Furthermore, Best Melting Aluminum Electric Furnace Factory has invested in research and development to constantly improve their products. This dedication to innovation has led to the development of energy-efficient electric furnaces that minimize waste and reduce operating costs, providing long-term benefits to their clients.

To maintain high standards of quality, the factory has implemented rigorous testing and quality control measures at every stage of the production process. This ensures that each electric furnace that leaves their facility meets or exceeds industry standards, providing customers with peace of mind and confidence in their investment.

In addition to their dedication to producing high-quality products, Best Melting Aluminum Electric Furnace Factory is also known for their exceptional customer service. Their team of experienced professionals is committed to providing personalized support and guidance to help clients select the right electric furnace for their specific needs.

As a result of their commitment to excellence, Best Melting Aluminum Electric Furnace Factory has been recognized as a top manufacturer in the industry. Their continued success is a testament to their unwavering dedication to quality, innovation, and customer satisfaction.

Moving forward, the factory is focused on expanding their market reach and further enhancing their product offerings. They are dedicated to remaining at the forefront of the industry and continue to provide the best electric furnaces for melting aluminum and other metals.

In conclusion, Best Melting Aluminum Electric Furnace Factory has established itself as a top manufacturer in the industry, known for their high-quality products, innovative solutions, and exceptional customer service. Their commitment to excellence and continuous improvement has positioned them as a trusted partner for businesses in need of reliable electric furnaces for melting aluminum.

Company News & Blog

Top Zinc Melting Furnace Factories: Discover the Best Manufacturers in the Industry

Title: Advancements in Zinc Melting Furnace Technology Revolutionize the IndustryIntroduction:Zinc melting furnace factories play a crucial role in the manufacturing process of various industries, including automotive, construction, and electronics. These factories are responsible for melting and refining zinc to its molten form, which is then used for various applications. With technological advancements, several manufacturers have made significant strides in improving these furnaces' efficiency, safety, and environmental impact. In this article, we explore the recent developments in zinc melting furnace technology and their impact on the industry.1. Enhanced Efficiency through Innovative Designs:Leading zinc melting furnace manufacturers have been focusing on improving efficiency to meet the growing demands of zinc-consuming industries. They have developed advanced designs that optimize heat transfer, resulting in faster and more efficient melting processes. These innovative designs utilize various methods such as induction heating, electric resistive heating, or fossil fuel combustion to achieve optimal melting conditions.Furthermore, precise temperature control mechanisms and advanced insulation materials have been integrated into these furnaces, minimizing heat loss and enabling uniform melting throughout the entire process. As a result, manufacturers can achieve higher throughput capacities while reducing energy consumption, ultimately leading to cost savings and increased productivity.2. Emphasis on Safety Measures:Ensuring worker safety is of utmost importance in zinc melting furnace factories. Recent advancements have brought forth enhanced safety features, making the operating environment safer for workers. Furnaces now come equipped with sensor-based systems that continuously monitor various parameters like temperature, pressure, and gas leakage. In the event of any abnormalities or hazardous situations, these systems can automatically shut down the furnace or trigger alarms, thereby preventing accidents and ensuring a secure work environment.Moreover, improved ventilation and exhaust systems have been implemented to minimize the health risks associated with exposure to metal fumes and other harmful byproducts generated during the melting process. These advancements have significantly reduced the health hazards for workers, leading to improved overall well-being and better work conditions.3. Environmental Sustainability:Zinc melting furnace factories have made notable progress in reducing their environmental footprint. Manufacturers have adopted cleaner and more sustainable energy sources, such as electricity from renewable sources or use of cleaner fuels like natural gas, minimizing greenhouse gas emissions. Additionally, advanced filtration systems have been introduced to capture and treat harmful byproducts like particulate matter, sulfur dioxide, and nitrogen oxides generated during the melting process.Furthermore, recycling initiatives have gained momentum, allowing for the recycling and reuse of zinc scrap and dross generated during the manufacturing process. This significantly reduces waste disposal, conserves natural resources, and promotes a circular economy approach.Conclusion:Recent advancements in zinc melting furnace technology have revolutionized the industry, bringing forth numerous benefits such as enhanced efficiency, improved safety measures, and a reduced environmental impact. The integration of innovative designs, refined temperature control mechanisms, and advanced safety features have enabled manufacturers to achieve higher productivity while safeguarding the well-being of workers. Moreover, the adoption of sustainable practices, including the use of cleaner energy sources and recycling initiatives, have promoted environmental sustainability within the industry.As the demand for zinc in various industries continues to grow, it is encouraging to witness the continuous efforts made by zinc melting furnace factories to push the boundaries of technological innovation. These advancements not only contribute to the industry's growth but also address the pressing concerns of efficiency, safety, and sustainability.

Discover the Secrets of Steel Melting Forges for Efficient Metal Transformation

[News Content]Steel Melting Forge Facility Increases Production Capacity, Boosting Company's Competitive Advantage[City, Date] – In an effort to expand their production capabilities and enhance overall efficiency, [Company Name] has successfully commissioned a new steel melting forge facility at their manufacturing plant. With this strategic investment, the company aims to meet the growing demand for high-quality steel products and strengthen its position in the market.The state-of-the-art steel melting forge, equipped with cutting-edge technology, boasts an impressive range of features that streamline the production process. It offers precision control over the melting process, ensuring superior material quality and consistency. The facility is also designed to minimize energy consumption, leading to both environmental and cost-saving benefits.By investing in the new steel melting forge, [Company Name] is geared towards significantly increasing its production capacity. The facility's advanced automation systems allow for continuous and uninterrupted production, reducing downtime and optimizing output. This will enable the company to deliver orders to customers more efficiently and promptly, thereby improving customer satisfaction and maintaining a leading position in the industry.[Company Name], a renowned player in the steel manufacturing industry, has continuously strived to integrate the latest technological advancements into its operations. The introduction of the steel melting forge further reinforces the company's commitment to innovation and growth.With this new addition, [Company Name] aims to cater to a wider range of industries, including automotive, construction, and machinery manufacturing. The facility's ability to melt various grades of steel, such as carbon steel, stainless steel, and alloy steel, ensures that the company can meet diverse customer requirements in terms of material specifications and performance characteristics."Expanding our production capabilities is crucial to meeting the evolving needs of our customers," said [Company Name]'s CEO. "The steel melting forge facility will play a pivotal role in strengthening our market position and increasing our competitiveness."Moreover, the new facility aligns with [Company Name]'s commitment to sustainability and reducing its environmental footprint. By incorporating energy-efficient technologies into the steel melting process, the company aims to minimize carbon emissions and optimize resource utilization. This investment not only benefits the business but also demonstrates [Company Name]'s dedication to being a responsible corporate citizen.To uphold its high standards of quality assurance, [Company Name] has also invested in a comprehensive inspection and testing system within the steel melting forge facility. This system enables continuous monitoring of the molten steel composition, ensuring compliance with stringent quality control standards. By doing so, the company guarantees consistent product quality and reliability, reinforcing customer trust in its offerings.The new steel melting forge facility is expected to generate employment opportunities, benefiting both the local community and the wider economy. Its implementation showcases [Company Name]'s commitment to fostering economic growth through sustained investment and innovation.With the commissioning of the steel melting forge facility, [Company Name] is poised to solidify its position as a market leader in the steel manufacturing sector. The increased production capacity, along with enhanced operational efficiency, will enable the company to address market demands effectively and cater to a diverse customer base, ultimately driving its growth and success.About [Company Name]:[Company Name] is a globally recognized steel manufacturing company, dedicated to delivering high-quality steel products to various industries. With a commitment to innovation, sustainability, and customer satisfaction, [Company Name] remains at the forefront of the steel industry, driving its growth and success.Press Contact:[Name][Designation][Company Name][Phone][Email]

Discover an Efficient Solution for Your Furnace Needs

Title: Next-Generation Furnace Showcases Groundbreaking Innovations in Casting IndustryIntroduction:In a bid to revolutionize the casting industry, a renowned furnace manufacturer has unveiled its latest product, the groundbreaking Cast Master Furnace. This state-of-the-art furnace is set to redefine the standards of casting technology with its advanced features and efficient performance. The new Cast Master Furnace signifies a significant leap forward, promising unparalleled precision, productivity, and sustainability for casting professionals worldwide.1. Advanced Technology Enhancing Precision:The Cast Master Furnace integrates cutting-edge technology to provide a higher level of precision in the casting process. Incorporating advanced sensors and sophisticated software, the furnace ensures accurate temperature control, preventing overheating or underheating of the metal alloys. This breakthrough technology guarantees exceptional product quality and reduces wastage, enabling casting professionals to achieve the desired results consistently.Furthermore, the furnace's innovative design enables precise monitoring of various parameters such as gas flow, pressure, and air ratios, ensuring optimized combustion. This not only enhances energy efficiency but also minimizes environmental impact, making the Cast Master Furnace a sustainable choice for casting operations.2. Increased Productivity with Smart Features:Recognizing the importance of productivity in the casting industry, the Cast Master Furnace offers a host of smart features that streamline the casting process and reduce downtime. The inclusion of remote monitoring capabilities allows operators to track the furnace's performance, identify potential issues, and make real-time adjustments from a centralized control panel. This remote operation feature enhances efficiency and reduces the need for manual intervention, resulting in improved productivity levels.In addition to remote monitoring, the Cast Master Furnace incorporates an intelligent scheduling system that optimizes the casting cycle based on various factors like alloy composition, mold complexity, and cooling requirements. By automating the scheduling process, the furnace allows for efficient use of resources, thereby maximizing productivity and reducing production costs.3. Sustainability and Energy Efficiency:The Cast Master Furnace is designed to promote sustainable practices and reduce energy consumption in the casting industry. Utilizing state-of-the-art insulation materials, the furnace minimizes heat loss, improving energy efficiency while ensuring a safer working environment.Moreover, the furnace employs a multi-stage filtration system to capture and treat harmful emissions, significantly reducing pollutants released into the atmosphere. This commitment to environmental responsibility aligns with global efforts to mitigate the carbon footprint of industrial processes, making the Cast Master Furnace an environmentally-conscious choice.4. Collaborative Approach for Industry Advancement:The introduction of the Cast Master Furnace demonstrates the manufacturer's commitment to fostering collaboration within the casting industry. The company has actively engaged with casting professionals, incorporating their valuable feedback and insights during the development phase. By combining extensive industry experience with cutting-edge technology, the manufacturer has addressed the specific challenges faced by casting professionals, resulting in an innovative furnace tailored to their unique requirements.Furthermore, the company offers comprehensive technical support, including training programs and prompt assistance from a team of experts. By nurturing a collaborative environment, the manufacturer strives to empower casting professionals with the necessary knowledge and skills to optimize their casting operations effectively.Conclusion:As the casting industry moves towards a more technologically advanced era, the Cast Master Furnace leads the way with its groundbreaking features, exceptional precision, and commitment to sustainability. This advanced furnace promises to revolutionize the casting process, enabling professionals to achieve higher levels of accuracy, productivity, and energy efficiency. With its innovative design and comprehensive support system, the Cast Master Furnace is set to become the choice of casting professionals worldwide, positioning the industry for a brighter and more sustainable future.

Innovative Induction Furnace Tech Enhances Steel Manufacturing Efficiency

Title: Revolutionary Induction Arc Furnace: A Breakthrough in Modern Steel ProductionSubtitle: Company X Introduces Cutting-Edge Technology Set to Revolutionize the Steel IndustryDate: [Date][City], [State] - Company X, a global leader in innovative industrial solutions, has unveiled its latest breakthrough in steel production technology - the Induction Arc Furnace. This groundbreaking invention promises to revolutionize the steel manufacturing process, offering numerous advantages over traditional methods. The Induction Arc Furnace is set to become a game-changer in the industry, significantly improving efficiency, reducing environmental impact, and boosting overall productivity.The Induction Arc Furnace employs a unique combination of advanced induction heating technology and arc furnace principles. By merging the most effective features of both processes, Company X has developed a highly efficient furnace that surpasses traditional methods in multiple ways. One of the most significant benefits of the Induction Arc Furnace is its exceptional energy efficiency. Unlike conventional steel production, which heavily relies on fossil fuels, this new technology utilizes electricity as the primary energy source. As a result, it significantly reduces carbon emissions and minimizes the industry's overall environmental impact. The furnace also boasts an incredibly high power factor, ensuring optimal energy utilization, further enhancing its sustainability and cost-effectiveness.The technological advancements embedded within the Induction Arc Furnace also enable rapid melting and precise temperature control. Traditional methods often require an extended period to heat the raw materials to the desired temperature. However, the Induction Arc Furnace excels in this aspect, efficiently melting metal charges in a matter of minutes. This accelerated process not only saves valuable production time but also allows for greater flexibility and responsiveness in meeting market demands.Furthermore, the advanced temperature control mechanisms incorporated in the furnace optimizes the steel manufacturing process. The precise regulation of temperature ensures consistent product quality, reducing the risk of imperfections and increasing overall yield. This level of accuracy is vital in meeting stringent industry standards and client specifications, making the Induction Arc Furnace an attractive solution for steel manufacturers worldwide.The Induction Arc Furnace is also highly versatile, capable of processing a vast array of steel materials. This flexibility allows manufacturers to utilize various metal scrap types and grades, reducing waste and contributing to a more sustainable production cycle. The furnace's adaptability and compatibility with countless steel alloys make it a valuable tool for diverse industries, including automotive, construction, and aerospace.To accompany this innovative technology, Company X provides comprehensive technical support and expertise. Through its team of highly skilled engineers, the firm offers installation, training, and ongoing maintenance services. This commitment to customer satisfaction ensures seamless integration of the Induction Arc Furnace into existing manufacturing processes, allowing clients to fully leverage its capabilities and optimize their production cycles.Eager to penetrate global markets, Company X has already received overwhelming interest from major steel manufacturers worldwide. The company's technologically advanced Induction Arc Furnace presents a compelling alternative to traditional steel production methods, offering enhanced efficiency, reduced environmental impact, and greater cost-effectiveness.The introduction of this revolutionary furnace sets a new benchmark in modern steel manufacturing. Company X's commitment to continuous innovation reinforces its position as a trusted partner in shaping the future of the industry. With this pioneering technology, the steel manufacturing sector takes a significant step forward, aligning itself with sustainable practices and meeting the evolving needs of a rapidly changing world.As the global steel industry strives towards more efficient and environmentally responsible operations, the Induction Arc Furnace offers a beacon of hope and progress. Company X's breakthrough technology will undoubtedly reshape the steel production landscape, setting new industry standards for quality, efficiency, and sustainability.In conclusion, the Induction Arc Furnace represents a pivotal moment in the steel industry's evolution. With its superior efficiency, reduced environmental impact, and unparalleled flexibility, this groundbreaking technology will catalyze change, redefine process effectiveness, and accelerate progression towards a greener and more progressive future.

Top Chinese Manufacturer of Digital Melting Furnaces Offers Premium Quality Products to Global Market

[News]Digital Melting Furnace Manufacturer in China: Revolutionizing the Metal Industry[City, Date] - With the steady rise in global demand for metal products, Chinese digital melting furnace manufacturers have stepped up their game by innovating advanced technology and providing industry-leading solutions. One such company, which demands attention, is a leading manufacturer in China, revolutionizing the metal industry with their cutting-edge digital melting furnace technology.Founded several decades ago, this company has proven itself as a pioneer in the field of digital melting furnaces. Their vision to transform the way metals are melted and molded has set them apart from their competitors. By constantly pushing the boundaries of innovation and embracing new technologies, they have carved out a significant position in the market.The core principle behind the success of this company lies in their commitment to producing high-quality, energy-efficient, and technologically advanced digital melting furnaces. Their extensive range of products includes induction melting furnaces, gas-fired melting furnaces, electric arc furnaces, and vacuum arc melting furnaces, among others. This wide variety allows their customers to choose the furnace best suited to their specific requirements.One of the primary advantages of their digital melting furnaces is their precise temperature control, resulting in higher efficiency and reduced energy consumption. The incorporation of advanced sensors and an automated control system ensures accurate temperature control, eliminating any guesswork or manual errors. This not only saves valuable energy but also guarantees better quality metal output.Furthermore, the incorporation of digital interfaces and user-friendly controls has simplified the operation of these melting furnaces. The intuitive touch-screen displays, along with comprehensive manuals and online support, make it easy for operators to understand and operate the equipment efficiently.In line with their commitment to sustainability, this manufacturer has also integrated eco-friendly features into their digital melting furnace range. Advanced filtration systems remove harmful emissions, reducing environmental impact. By adopting these measures, companies using these digital melting furnaces can proudly contribute to a greener and cleaner industry.The advantages of this company's digital melting furnaces are already being recognized by major players in the metal industry. Their furnaces have become the go-to choice for industries involved in recasting, foundries, and research laboratories across the globe. The versatility of their products allows these manufacturers to cater to a wide range of metal alloys and applications.To support their customers, the company maintains an excellent customer service department. Their team of experienced professionals ensures prompt and reliable after-sales support, including technical assistance and spare parts availability. This commitment to customer satisfaction has earned them a strong reputation both domestically and internationally.Looking to the future, this manufacturer remains committed to continuous improvement and innovation. R&D efforts are constantly underway to explore new materials, enhance furnace productivity, and develop smarter solutions for the metal industry. They aim to solidify their position as the leading digital melting furnace manufacturer not just in China but around the world.With their unwavering commitment to quality, energy efficiency, and technological advancement, this digital melting furnace manufacturer from China is revolutionizing the metal industry. They have set a benchmark for others to follow, reinforcing China's position as a global manufacturing powerhouse. As the demand for metal products continues to grow, the advanced solutions provided by this industry-leading manufacturer will prove invaluable to professionals and businesses alike.About [Company Name]:[Company Name] is a renowned digital melting furnace manufacturer headquartered in China. With decades of experience, they specialize in providing advanced technological solutions for the metal industry. Their commitment to innovation, quality, and customer satisfaction has made them a trusted name not just in China but internationally. For more information, visit [Company Website].

Top Suppliers for Vacuum Induction Equipment

Vacuum Induction Suppliers announces new partnership with leading global technology companyVacuum Induction Suppliers, a leading provider of high-performance vacuum induction furnaces, is excited to announce its new partnership with a leading global technology company. This partnership aims to combine the expertise and innovation of both companies to provide cutting-edge solutions for the aerospace, automotive, and energy industries.Vacuum Induction Suppliers has built a strong reputation in the industry for its advanced vacuum induction furnaces that are used for the melting, refining, and casting of high-performance metals and alloys. The company's state-of-the-art equipment is known for its precision, reliability, and energy efficiency, making it a top choice for manufacturers seeking to produce high-quality components.With this new partnership, Vacuum Induction Suppliers will have access to the technology company's extensive research and development capabilities, as well as its global network of resources. This collaboration will enable Vacuum Induction Suppliers to further enhance its product offerings and provide customers with even more advanced solutions for their specific needs.The CEO of Vacuum Induction Suppliers, expressed his enthusiasm for the new partnership, stating that "This collaboration with a leading global technology company is a significant milestone for us. It will allow us to leverage their expertise and resources to further drive innovation and meet the evolving needs of our customers. We are confident that this partnership will result in the development of groundbreaking technologies that will benefit the industries we serve."The partnership will also focus on the development of sustainable and environmentally friendly solutions for the manufacturing industry. By combining their knowledge and expertise, Vacuum Induction Suppliers and the technology company aim to create more energy-efficient and eco-friendly processes that will help reduce the environmental impact of manufacturing operations.In addition to product development, the partnership will also include joint research initiatives and knowledge sharing between the two companies. This will help to foster a culture of innovation and continuous improvement, as well as strengthening the position of both companies as leaders in their respective fields.The technology company's commitment to sustainability and environmental responsibility aligns with Vacuum Induction Suppliers' own values, making this partnership a natural fit. Both companies share a common goal of driving positive change in the industry through innovation and collaboration.Customers of Vacuum Induction Suppliers can expect to benefit from the new partnership through access to even more advanced and cutting-edge solutions for their manufacturing needs. The combination of Vacuum Induction Suppliers' industry-leading equipment and the technology company's expertise will result in the development of next-generation technologies that will help customers stay ahead of the curve.As the partnership begins to take shape, Vacuum Induction Suppliers anticipates a significant impact on the industry. By working together, the two companies aim to set new standards for excellence in the manufacturing of high-performance metals and alloys, while also contributing to a more sustainable and environmentally friendly future for the industry.Overall, the new partnership between Vacuum Induction Suppliers and the leading global technology company holds great promise for the future of manufacturing. By combining their strengths and expertise, both companies are poised to create groundbreaking advancements that will benefit their customers and the industry as a whole. This collaboration represents a significant step forward in driving innovation and sustainability in the manufacturing sector.

High-quality Kiln For Efficient Copper Melting

For Immediate ReleaseNew Kiln for Melting Copper Revolutionizes Manufacturing Process[City, State] – In a significant leap forward for the manufacturing industry, [Company Name], a leading provider of industrial equipment, has recently unveiled its latest innovation: a cutting-edge kiln for melting copper. This state-of-the-art device is set to transform the way copper is melted and processed, offering a more efficient and cost-effective solution for businesses in the industry.Unlike traditional methods of melting copper, which often involve high energy consumption and produce harmful emissions, the new kiln from [Company Name] utilizes advanced technology to provide a more sustainable and eco-friendly alternative. The kiln is designed to operate at optimal efficiency, significantly reducing energy consumption and minimizing environmental impact. This innovation is in line with [Company Name]'s commitment to sustainability and its dedication to developing advanced solutions that benefit both businesses and the environment.The new kiln is also equipped with a range of smart features that allow for precise temperature control and efficient operation. This level of automation not only ensures consistent and high-quality results but also reduces the need for manual intervention, thereby streamlining the manufacturing process and improving overall productivity. With the ability to melt copper at a faster rate and with greater precision, businesses can expect to see significant improvements in their production capabilities and product quality."We are thrilled to introduce our latest kiln for melting copper, which represents a major advancement in industrial manufacturing technology," said [Spokesperson Name], [Title] at [Company Name]. "This innovative device reflects our ongoing commitment to delivering cutting-edge solutions that address the evolving needs of the industry. By incorporating the latest technologies, we are able to offer a more sustainable and efficient alternative for businesses seeking to enhance their copper melting capabilities."The launch of the new kiln comes at a time when the demand for copper is poised to grow significantly, driven by its essential role in various industries, including electronics, construction, and renewable energy. As businesses seek to meet this increasing demand, the need for efficient and reliable copper melting solutions is more critical than ever. The new kiln from [Company Name] is poised to address this need by providing a solution that not only improves the manufacturing process but also reduces operational costs and environmental impact.In addition to its advanced features, the new kiln for melting copper from [Company Name] is backed by the company's renowned service and support. With a team of experienced professionals and a global network of service centers, [Company Name] is committed to ensuring that businesses have access to the guidance and assistance they need to maximize the potential of their new kiln. This comprehensive support further underscores [Company Name]'s dedication to delivering complete solutions that meet the diverse needs of its customers.As the manufacturing industry continues to evolve, the introduction of the new kiln for melting copper from [Company Name] represents a significant milestone. With its advanced technology, sustainable design, and commitment to customer support, this innovative device is set to redefine the standard for copper melting and processing. Businesses that invest in this cutting-edge solution can expect to achieve new levels of efficiency, productivity, and sustainability, positioning them for long-term success in a rapidly changing market.For more information about the new kiln for melting copper and other industrial equipment solutions from [Company Name], please visit [Company Website].Contact:[Company Name][Contact Person][Address][Phone Number][Email Address]

Metal Melting Furnace Manufacturers in China: Key Players, Market Trends and Growth Opportunities

China Induction Metal Melting Furnace Suppliers Leverage Advanced Technology and Innovation to Boost Industry GrowthWith the rapidly growing demand for metal melting furnaces across industries worldwide, China Induction Metal Melting Furnace Suppliers have emerged as leading players in the market. These suppliers are known for their commitment to advanced technology and innovation, enabling them to provide high-quality products that meet the diverse needs of their customers.China has long been recognized as a manufacturing hub, and its induction metal melting furnace suppliers have gained significant traction in recent years. The country's robust infrastructure, skilled workforce, and focus on technological advancements have positioned it as a key player in the global market for metal melting furnaces.One prominent example of a leading China-based induction metal melting furnace supplier is {}. With years of experience in the industry, they have established a solid reputation for manufacturing reliable and efficient furnaces. However, we will avoid mentioning the specific brand name to maintain neutrality.The company employs advanced induction heating technology and sophisticated processes to ensure the highest quality products. Using electromagnetic induction, these furnaces can generate intense heat within a short period, allowing for rapid and efficient metal melting.In addition to their cutting-edge technology, {} places great emphasis on research and development. The company has a dedicated team of engineers and technicians who constantly work towards refining their furnace designs and optimizing their performance. This commitment to innovation has enabled them to stay ahead of the competition and deliver state-of-the-art products that meet the evolving needs of their customers in diverse industries.One of the key advantages of induction metal melting furnaces is their energy efficiency. These furnaces have a high heat transfer rate, reducing energy consumption and minimizing carbon emissions. This eco-friendly approach is particularly important in today's climate-conscious world.Furthermore, {} offers a wide range of customization options to cater to the specific requirements of different industries. From small-scale operations to large industrial facilities, their furnaces can be tailored to suit various capacities and operational demands. This flexibility and versatility have made their induction metal melting furnaces highly sought after in industries such as automotive, aerospace, electronics, and jewelry manufacturing.Quality control is another area where China Induction Metal Melting Furnace Suppliers have excelled. {} employs stringent quality control measures at every stage of the production process, ensuring that each furnace meets the highest standards of reliability and durability. Moreover, they are compliant with international safety regulations, providing customers with the assurance that their operations will run smoothly and efficiently.The global market for metal melting furnaces is expected to witness substantial growth in the coming years. This can be attributed to the increasing demand for metals in various sectors, ranging from automotive and construction to electronics and renewable energy. China's induction metal melting furnace suppliers are well-positioned to capitalize on this growth, thanks to their commitment to technological advancements and customer-centric approach.In conclusion, China Induction Metal Melting Furnace Suppliers, such as {}, have emerged as leaders in the market due to their dedication to advanced technology and innovation. Their ability to deliver high-quality, energy-efficient, and customizable furnaces has made them the preferred choice for industries worldwide. With the global demand for metal melting furnaces on the rise, these suppliers are poised for continued growth and success.

Top Supplier of Rotary Melting Furnace for Industrial Applications

The rotary melting furnace is a crucial piece of equipment in the metal casting and recycling industry. Its ability to efficiently melt and refine various types of metal makes it an indispensable tool for many businesses. As the demand for high-quality rotary melting furnaces continues to grow, the need for reliable and reputable suppliers has become increasingly important.In this regard, [Company Name] has established itself as a leading supplier of rotary melting furnaces in the industry. With a proven track record of providing top-notch equipment and exceptional customer service, the company has earned a stellar reputation among its clients.Founded in [year], [Company Name] has quickly become a trusted name in the manufacturing and supply of industrial equipment. The company's commitment to delivering high-quality products and innovative solutions has made it a preferred choice for many businesses looking to invest in reliable and efficient machinery.The company's rotary melting furnaces are designed to meet the demands of various metal melting and refining processes. With a focus on energy efficiency, durability, and precision, these furnaces are capable of handling a wide range of metals, including aluminum, copper, and zinc. This versatility makes them an ideal choice for businesses operating in diverse sectors of the metal industry.One of the key features that sets [Company Name]'s rotary melting furnaces apart is their advanced technology and design. The company's team of experienced engineers and technicians has leveraged their expertise to develop furnaces that are not only efficient but also environmentally friendly. By incorporating state-of-the-art heating elements and combustion systems, these furnaces are able to achieve high melting rates while minimizing energy consumption and emissions.In addition to their technical superiority, [Company Name]'s rotary melting furnaces are also known for their reliability and low maintenance requirements. This is a result of the company's stringent quality control processes and use of high-grade materials in the construction of their equipment. As a result, clients can count on these furnaces to deliver consistent performance and withstand the rigors of heavy-duty industrial operations.Furthermore, [Company Name] takes great pride in its dedication to customer satisfaction. The company's team is committed to providing comprehensive support to clients, from the initial consultation to after-sales service. This includes assisting with the installation and commissioning of the equipment, as well as offering ongoing technical support and maintenance services.The company's customer-centric approach has earned it a loyal clientele who value the peace of mind that comes with knowing that [Company Name] is there to support their operations. This level of commitment has helped the company build long-lasting relationships with its customers and solidify its reputation as a reliable and trustworthy supplier.As the metal industry continues to evolve and grow, the demand for efficient and reliable rotary melting furnaces will only increase. In this dynamic environment, having a reliable supplier like [Company Name] is essential for businesses looking to stay ahead of the curve and maintain a competitive edge.With its focus on innovation, quality, and customer satisfaction, [Company Name] is well-positioned to meet the evolving needs of the industry and continue to be a top choice for businesses seeking the best rotary melting furnaces on the market. Whether it's for metal casting, recycling, or other applications, clients can rest assured that they are in good hands with [Company Name] as their trusted supplier.

Iron Melting Furnace: Everything You Need to Know

Furnace For Iron Melting Revolutionizes Manufacturing IndustryThe manufacturing industry has always been a vital part of the global economy, and technological advancements have continuously push the industry forward. In line with this, the introduction of the new and innovative furnace for iron melting has been a game-changer for many companies in the manufacturing sector. This cutting-edge technology is set to revolutionize the way iron is melted and processed, paving the way for more efficient and cost-effective manufacturing processes.The new furnace, developed by a leader in industrial equipment manufacturing, is equipped with state-of-the-art features that make it stand out in the market. With its advanced temperature control and energy-efficient design, the furnace for iron melting offers a significant improvement over traditional melting methods. This technology is set to streamline the manufacturing process and help companies save both time and resources.The high-quality materials and precision engineering of the furnace ensure that it can withstand the rigorous demands of industrial use, making it a reliable and durable investment for companies looking to upgrade their manufacturing capabilities. The furnace is also designed for easy maintenance, reducing downtime and ensuring continuous operation for maximum productivity.In addition to its technical capabilities, the furnace for iron melting is also backed by a reliable and experienced company, [Company Name]. With a proven track record in providing advanced industrial equipment and innovative solutions, [Company Name] is a trusted partner for companies in the manufacturing industry. The company is committed to delivering excellence and reliability, and their dedication to customer satisfaction sets them apart in the market.The furnace for iron melting is just one example of the cutting-edge technologies and solutions that [Company Name] offers to their clients. From concept to completion, the company provides comprehensive support and expertise to help companies optimize their manufacturing processes and achieve their production goals. They understand the unique challenges that businesses face in the manufacturing industry, and they are committed to providing tailored solutions that meet their clients' specific needs.As the manufacturing industry continues to evolve, the demand for efficient and reliable equipment becomes increasingly important. The furnace for iron melting represents a significant advancement in the field, offering companies the opportunity to improve their operations and stay ahead of the competition. With its advanced features and robust design, this technology is poised to become an essential tool for companies looking to enhance their manufacturing capabilities.The introduction of the furnace for iron melting is a clear indication of [Company Name]'s commitment to innovation and excellence in the manufacturing industry. With their expertise and dedication to customer satisfaction, the company is well-positioned to drive positive change and help businesses achieve success in today's competitive market.In conclusion, the furnace for iron melting is set to revolutionize the manufacturing industry, offering companies a cost-effective and efficient solution for their iron melting needs. Backed by [Company Name]'s expertise and reliability, this cutting-edge technology is poised to become an essential part of modern manufacturing operations. As businesses continue to adapt to the demands of the global market, innovative solutions like the furnace for iron melting will play a crucial role in driving success and growth in the industry.