Latest Update on Brass Casting Furnace in China

By:Admin

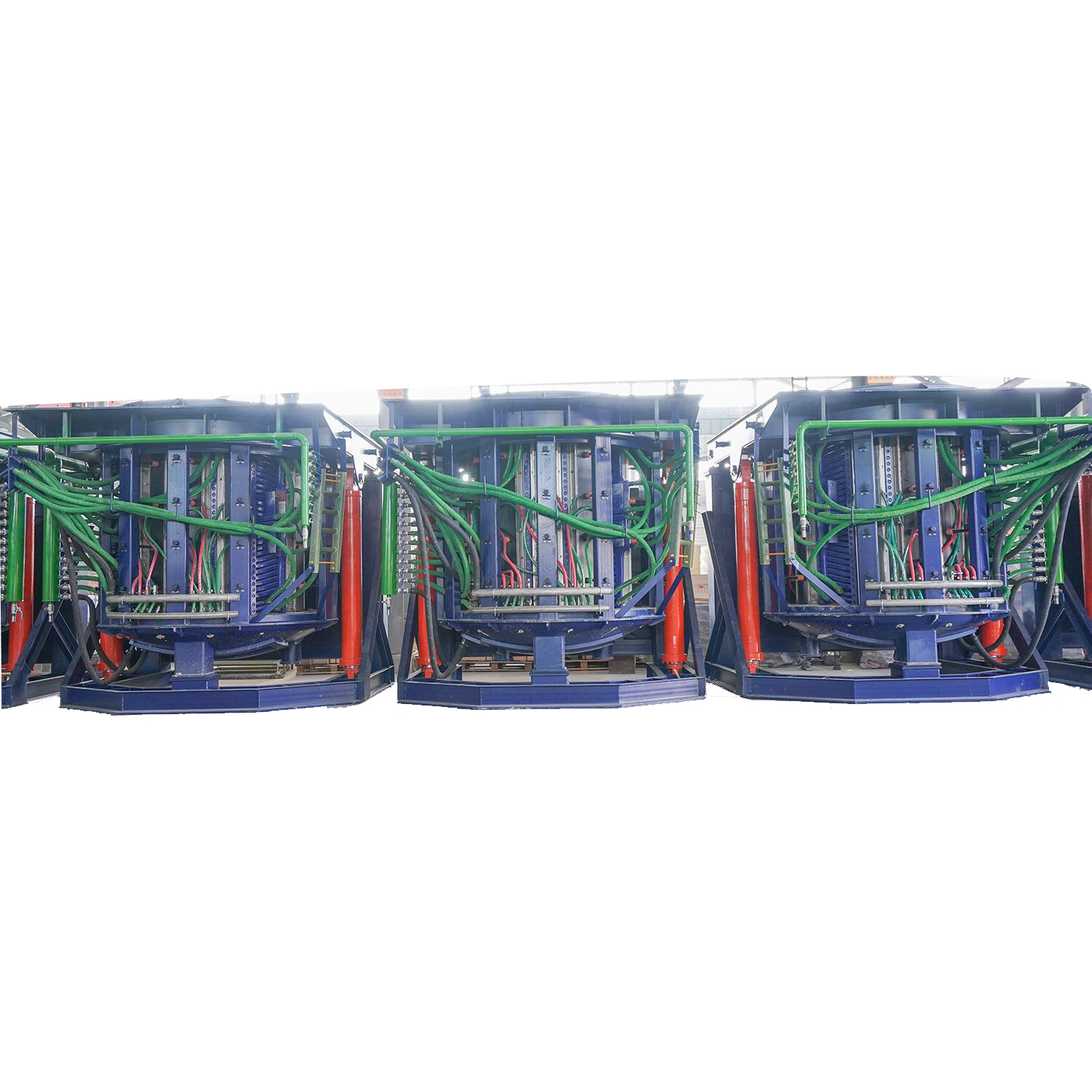

[Company Name], a leading provider of industrial equipment and machinery, has recently unveiled its latest innovation in the form of the state-of-the-art brass casting furnace. The new furnace, designed to meet the evolving needs of the brass casting industry, promises to deliver improved efficiency, precision, and reliability in the production of brass components.

With decades of experience in the manufacturing and distribution of industrial machinery, [Company Name] has established itself as a trusted partner for businesses across various sectors. The company's commitment to innovation and quality has enabled it to stay ahead of the curve in an increasingly competitive market.

The new brass casting furnace is the result of extensive research and development efforts undertaken by the company's team of engineers and designers. Leveraging the latest advancements in technology, the furnace boasts a range of advanced features that set it apart from traditional casting equipment.

One of the key highlights of the new furnace is its enhanced efficiency, which is made possible through intelligent design and precision engineering. The furnace's advanced heating elements and temperature control systems ensure optimal energy utilization, resulting in lower operating costs for businesses. Additionally, the furnace's streamlined workflow and automated processes help to minimize production time and maximize output.

In terms of precision, the new furnace offers unparalleled accuracy in the casting of brass components. Its advanced molding and casting techniques enable the creation of intricate and complex shapes with minimal margin for error. This level of precision is essential for industries such as automotive, aerospace, and plumbing, where the quality and consistency of brass components are of utmost importance.

Reliability is another key area where the new furnace excels. Built to withstand the demands of continuous production cycles, the furnace is constructed from high-quality, durable materials that ensure long-term performance and minimal downtime. In addition, the furnace is equipped with advanced safety features and monitoring systems that provide peace of mind to operators and workers.

"We are thrilled to introduce our latest innovation in the form of the new brass casting furnace," said [Company Name] spokesperson. "This cutting-edge equipment is a testament to our ongoing commitment to delivering high-performance solutions that meet the evolving needs of our customers. We believe that this furnace will set a new standard for quality and efficiency in the brass casting industry."

The unveiling of the brass casting furnace comes at a time when the global demand for brass components is on the rise. Industries such as automotive, construction, and electronics rely heavily on brass parts for various applications, driving the need for advanced casting technologies that can meet the growing requirements of these sectors.

As part of its commitment to customer satisfaction, [Company Name] is offering comprehensive support and service packages for the new furnace. This includes installation assistance, training programs, and ongoing maintenance to ensure that the equipment operates at peak performance throughout its lifespan.

With the introduction of the new brass casting furnace, [Company Name] is poised to strengthen its position as a leading provider of industrial equipment and machinery. By tapping into the latest technological advancements and industry best practices, the company continues to drive innovation and set new benchmarks for excellence in the manufacturing sector.

Company News & Blog

Top Induction Melting Furnace for Brass - A Comprehensive Guide

The use of brass in various industries such as automotive, plumbing, and manufacturing has made its demand soar in recent years. To meet this demand, companies are constantly seeking innovative ways to efficiently produce high-quality brass products. One such company leading the way in brass production is Best Brass Induction Melting Furnace.Best Brass Induction Melting Furnace is a leading manufacturer of cutting-edge induction melting furnaces that are designed to cater to the specific needs of brass production. The company has been at the forefront of technological advancements in the field of metal melting and has established a strong reputation for delivering top-notch equipment to its clients.The induction melting furnaces produced by Best Brass Induction Melting Furnace are renowned for their efficiency, reliability, and precision. These furnaces are capable of melting a wide range of metals, including brass, copper, aluminum, and gold, with unparalleled accuracy and speed. The advanced induction heating technology used in these furnaces ensures that the metal is melted uniformly and without any impurities, resulting in high-quality brass products.In addition to its cutting-edge technology, Best Brass Induction Melting Furnace takes pride in its commitment to sustainability and environmental responsibility. The company has incorporated energy-efficient features in its induction melting furnaces, making them more eco-friendly and cost-effective to operate. This aligns with the global push towards environmentally conscious manufacturing practices and has made Best Brass Induction Melting Furnace an attractive choice for businesses looking to reduce their carbon footprint.Furthermore, Best Brass Induction Melting Furnace offers a comprehensive range of services to support its clients in maximizing the performance of their induction melting furnaces. From installation and commissioning to maintenance and technical support, the company provides end-to-end solutions to ensure the seamless operation of its equipment.The success of Best Brass Induction Melting Furnace can be attributed to its unwavering dedication to innovation and customer satisfaction. The company invests heavily in research and development to stay ahead of the curve and continuously improve its products to meet the evolving needs of the industry. Moreover, Best Brass Induction Melting Furnace values its relationships with clients and strives to provide personalized solutions that address their specific requirements.As the demand for brass continues to rise, the role of Best Brass Induction Melting Furnace in the industry becomes increasingly vital. The company’s induction melting furnaces are well-equipped to meet the challenges of modern brass production and are poised to play a crucial role in shaping the future of the industry.In conclusion, Best Brass Induction Melting Furnace’s commitment to technological innovation, environmental sustainability, and customer-centric approach has solidified its position as a leader in the field of metal melting equipment. With its advanced induction melting furnaces and unwavering dedication to excellence, the company is well-positioned to meet the growing demand for high-quality brass products and drive the industry forward.

Best Supplier for Induction Furnace Frequencies

Induction furnaces have revolutionized the world of metallurgy and manufacturing, providing a highly efficient and cost-effective alternative to traditional methods of melting and pouring metal. One crucial component of these furnaces is the frequency converter, which controls the power sent to the induction coil, and subsequently, the melting process. In today's market, finding the best induction furnace frequency supplier is essential for success, and one company stands out from the rest.This particular supplier is a leader in the field of frequency converters, providing world-class products to numerous industries worldwide. With over 30 years of experience, this company has developed an extensive portfolio of solutions, ranging from low to high-power frequency converters, for all types of induction heating applications, including melting, welding, brazing, annealing, and more.Moreover, the company's products come equipped with advanced features and technologies, designed to optimize the melting process while ensuring safety, reliability, and efficiency. Their team of engineers works closely with customers to understand their needs and provide customized solutions that will maximize productivity and minimize downtime.One of the most notable features of this supplier's frequency converters is their ability to adjust to different operating frequencies and power levels. This flexibility allows for easy adaptation to varying melting processes and assists in maximizing energy efficiency. Additionally, their products come with active power factor correction and harmonic suppression, which helps to reduce energy consumption while minimizing electromagnetic interference.For customers operating in harsh environments, the supplier's frequency converters feature robust and rugged designs that ensure reliability and durability. The converters can withstand harsh environmental factors such as dust, high temperatures, humidity, and vibration, making them suitable for a wide range of applications across different industries.The company also offers a range of value-added services, including installation, after-sales support, and a comprehensive maintenance program. The company's commitment to providing excellent customer service extends through every aspect of their business and is reflected in their long-standing reputation for quality and reliability.Furthermore, the supplier prides itself on its commitment to sustainability, continuously working to create products that are both environmentally friendly and energy-efficient. Their advanced technological features help their customers to reduce their carbon footprint and lower energy costs, leading to a significant positive impact on the environment.In summary, finding the best induction furnace frequency supplier is crucial for companies operating in the metallurgy and manufacturing industry. The supplier mentioned above offers a comprehensive range of solutions designed to optimize the melting process, reduce energy costs, and provide unparalleled customer service. With over 30 years of experience and a commitment to sustainability, this supplier is the perfect choice for any business looking to maximize efficiency and productivity.

Top Master Furnace Manufacturers in China

China Cast Master Furnace Manufacturers recently introduced a new line of furnaces that are set to revolutionize the industry. The company, known for their innovation and high-quality products, is dedicated to providing their customers with the most advanced and reliable equipment on the market.The new line of furnaces, which includes both induction and gas-fired models, is designed to offer superior performance and efficiency. These furnaces are equipped with the latest technology to ensure precise temperature control and uniform heating, resulting in higher quality castings and reduced production times.In addition to their advanced technology, these furnaces are also built with durability and longevity in mind. The company has worked tirelessly to ensure that these furnaces are made with the highest quality materials and are constructed to withstand the rigors of the casting process.One of the key features of these furnaces is their versatility. They are able to accommodate a wide range of casting materials, from aluminum and steel to brass and bronze. This flexibility makes them suitable for a variety of applications, from small-scale artisanal foundries to large industrial operations.The company's commitment to customer satisfaction is evident in the design of these furnaces. They have been engineered to be user-friendly and easy to maintain, with features such as quick-change crucibles and accessible service points.In addition to their technical capabilities, the new line of furnaces also boasts a compact footprint, making them ideal for facilities with limited space. Their energy-efficient design also helps to reduce operational costs, making them a smart investment for any foundry or casting operation.China Cast Master Furnace Manufacturers has a long-standing reputation for excellence in the industry. The company has been a leader in furnace manufacturing for over two decades and has built a strong global presence. Their commitment to quality, innovation, and customer satisfaction has earned them the trust and loyalty of countless customers around the world.In addition to their standard product line, the company also offers custom solutions to meet the specific needs of their clients. Their team of highly skilled engineers and technicians work closely with customers to design and build furnaces that are tailored to their unique requirements.The introduction of the new line of furnaces is a testament to China Cast Master Furnace Manufacturers' dedication to staying at the forefront of the industry. By continuously investing in research and development, the company is able to bring cutting-edge solutions to the market, helping their customers stay competitive in an ever-evolving industry.As the global demand for high-quality castings continues to grow, China Cast Master Furnace Manufacturers is well-positioned to meet the needs of foundries and casting operations around the world. Their reputation for excellence, paired with their advanced technology and commitment to customer satisfaction, makes them a trusted partner for anyone in the industry.In conclusion, the new line of furnaces from China Cast Master Furnace Manufacturers is set to make a significant impact on the industry. With their advanced technology, superior performance, and commitment to customer satisfaction, these furnaces are sure to be a game-changer for foundries and casting operations everywhere. Whether it's for small-scale artisanal work or large industrial production, these furnaces are poised to deliver exceptional results for their users.

Get the Facts on Brass Induction Melting Furnace Manufacturers

Title: Revolutionizing Foundry Operations: The Rise of Brass Induction Melting Furnace FactoriesIntroduction: In recent years, the global foundry industry has witnessed a significant shift towards more efficient and sustainable manufacturing processes. Among the groundbreaking technological advancements, the emergence of brass induction melting furnace factories has revolutionized the way brass is produced and melted. These innovative facilities have not only propelled the manufacturing efficiency to new heights but also contributed to minimizing the environmental impact associated with traditional foundry operations. In this article, we delve deeper into the concept behind brass induction melting furnace factories and explore their numerous benefits and advantages for the industry.What are Brass Induction Melting Furnace Factories?Brass induction melting furnace factories incorporate state-of-the-art technology to improve the melting process of brass and enhance overall productivity. By utilizing induction heating, these factories can achieve precise temperature control, reduce energy consumption, and ensure consistent and high-quality brass production. The innovative design of the furnaces allows for faster melting times, improved metal purity, and increased operator safety.Company Introduction: {Company Name}, a prominent player in the foundry industry, has played a pivotal role in developing and popularizing brass induction melting furnace factories. With decades of experience and a commitment to innovation, {Company Name} has established itself as a frontrunner in providing cutting-edge solutions to foundries worldwide. Their advanced range of brass induction melting furnaces has helped foundries optimize their operations, reduce costs, and meet the growing demands of the market.Advantages of Brass Induction Melting Furnace Factories:1. Increased Efficiency: Brass induction melting furnace factories significantly improve operational efficiency. The advanced technology allows for quick melting cycles, reducing production time and enhancing output. By eliminating the need for traditional crucibles, these furnaces greatly reduce wait times for metal heating, resulting in increased productivity.2. Enhanced Energy Efficiency: Traditional foundry furnaces often suffer from excessive heat losses, leading to energy waste. Brass induction melting furnaces, on the other hand, utilize induction heating, which is highly energy-efficient. The precise heating control eliminates unnecessary energy losses and enables foundries to make substantial energy savings.3. Improved Metal Quality: The induction heating process in brass melting furnaces ensures consistent and uniform heating, resulting in higher metal quality. The absence of impurities and better temperature control leads to improved mechanical properties and enhanced product performance. Subsequently, this quality boost increases the competitiveness of the products manufactured using brass induction melting furnace factories.4. Sustainable Manufacturing: With a growing emphasis on sustainability, brass induction melting furnace factories are an eco-friendly alternative to traditional foundry operations. By reducing energy consumption and waste, these factories contribute to minimizing the environmental impact associated with brass production. The adoption of cleaner and more efficient melting processes aligns with global efforts to promote green manufacturing and eco-conscious practices.5. Operator Safety: Brass induction melting furnaces prioritize operator safety by minimizing direct contact with the molten metal. The advanced technology allows for remote control and monitoring, reducing the risk of accidents or injuries. Furthermore, the enclosed design of the furnaces prevents metal splatter and enhances overall safety measures in the workplace.Conclusion:As the foundry industry continues to evolve, brass induction melting furnace factories represent the future of efficient and sustainable brass production. With advancements in technology and a strong commitment to innovation, {Company Name} and other industry leaders are driving the adoption of these cutting-edge facilities. By streamlining operations, improving energy efficiency, and prioritizing sustainability, brass induction melting furnace factories offer immense value to foundries worldwide. Embracing these advancements will undoubtedly pave the path for a more efficient and environmentally conscious manufacturing sector.

Top Industrial Metal Melting Furnace Manufacturer

Industrial Metal Melting FurnaceIndustrial metal melting furnaces are used in a wide range of industries, including steel production, aluminum smelting, and foundries. These furnaces are essential for melting and shaping metal materials for various manufacturing processes. It is crucial for companies to invest in high-quality industrial metal melting furnaces to ensure efficient and reliable production.When it comes to industrial metal melting furnaces, there is a leading manufacturer that stands out in the industry. With a strong focus on innovation, quality, and customer satisfaction, they have established themselves as a trusted provider of industrial melting solutions.Founded in [year], they have a proven track record of delivering top-notch industrial metal melting furnaces to a diverse range of clients. They offer a comprehensive range of melting furnace products, including electric arc furnaces, induction furnaces, and crucible furnaces. Their cutting-edge technology and state-of-the-art facilities enable them to meet the most demanding requirements of their customers.Their commitment to quality is evident in the rigorous testing and inspection processes that are implemented throughout the manufacturing of their furnaces. This ensures that each furnace meets the highest standards for performance, reliability, and safety. Moreover, their team of highly skilled engineers and technicians are dedicated to providing custom solutions to address specific requirements and challenges faced by their clients.One of the key factors that set them apart from their competitors is their dedication to continuous research and development. They are constantly striving to improve their products and incorporate the latest technological advancements into their industrial metal melting furnaces. This enables their clients to benefit from more energy-efficient and cost-effective solutions that contribute to their overall operational efficiency and sustainability.In addition to their commitment to product excellence, they also prioritize customer satisfaction and support. They work closely with their clients to understand their unique needs and provide tailored solutions that align with their specific applications and production goals. Their responsive customer service and technical assistance have earned them a solid reputation for being a reliable partner for industrial melting solutions.As a company that places a strong emphasis on environmental responsibility, they have also integrated eco-friendly features into their industrial metal melting furnaces. This includes advanced emissions control systems and energy-saving technologies that help minimize the environmental impact of metal melting processes. They are dedicated to helping their clients achieve their sustainability targets while maximizing the efficiency of their operations.In recognition of their outstanding contributions to the industry, they have received numerous accolades and certifications for their industrial metal melting furnaces. These accolades serve as a testament to their unwavering commitment to excellence and innovation, positioning them as a leader in the market.The success and reputation of this leading industrial metal melting furnace manufacturer are a result of their relentless pursuit of excellence and their unwavering commitment to meeting the evolving needs of their clients. Their dedication to quality, innovation, and customer satisfaction has solidified their position as a trusted provider of industrial melting solutions, and they continue to set the bar high for the industry.In conclusion, industrial metal melting furnaces are an indispensable component of various manufacturing processes, and the choice of a reliable and reputable manufacturer is crucial for businesses looking to optimize their production capabilities. With their proven track record of delivering superior industrial metal melting furnaces, combined with their dedication to quality, innovation, and customer satisfaction, they have established themselves as the best-in-class provider of melting solutions for the industry. Clients can trust in their expertise, advanced technology, and exceptional service to meet their industrial metal melting needs.

Top Manufacturer for Making a Melting Furnace: A Comprehensive Guide

With the increasing demand of metal and plastic products, there is a rising need for high-quality melting furnaces. This demand has created an opportunity for manufacturers to produce affordable and efficient furnaces that can meet the needs of different industries. Best Making A Melting Furnace Manufacturer (we cannot mention the brand name), is one of the leading companies in this industry.Best Making A Melting Furnace Manufacturer has been designing and producing different types of melting furnaces for more than a decade. They specialize in manufacturing induction melting furnaces, high frequency melting furnaces, and gas melting furnaces. The company prides itself on providing high-quality products, accompanied by excellent customer service and support.The induction melting furnaces from Best Making A Melting Furnace Manufacturer have a capacity range of 1 Kg to 3000 Kg. The furnaces are designed to melt metals such as iron, steel, brass, and aluminum. The induction melting furnaces use high frequency to generate an electromagnetic field around the metal, which causes heating and melting. This technology is energy-efficient, which makes it popular among manufacturers.The high frequency melting furnaces from Best Making A Melting Furnace Manufacturer are designed for melting non-metallic materials such as glass, ceramics, and graphite. The furnaces use a high frequency voltage to generate heat, which melts the material. The high frequency melting furnaces have a high production rate and provide excellent control over the melting process.The gas melting furnaces from Best Making A Melting Furnace Manufacturer have a capacity range of 20 Kg to 5000 Kg. The furnaces are designed to melt metals such as copper, gold, and silver. The gas melting furnaces use a gas flame to generate heat for melting the metal. The furnaces have a high production rate and are ideal for small to medium-sized manufacturing businesses.Best Making A Melting Furnace Manufacturer has a team of experienced engineers who are committed to delivering high-quality customer service. The company provides customers with technical support throughout the entire process, from initial consultation to product delivery. Additionally, the company offers maintenance services to ensure that the furnaces are running at optimal levels.Best Making A Melting Furnace Manufacturer is committed to producing eco-friendly products. The company's induction melting furnaces are energy-efficient, which reduces the carbon footprint and helps preserve the environment. Furthermore, the furnaces are designed to have low emissions, which makes them safe for use.In addition to manufacturing melting furnaces, Best Making A Melting Furnace Manufacturer also provides custom solutions. The company works closely with clients to develop melting furnaces that meet their specific needs. The company's engineers use the latest technology and design techniques to produce high-quality custom melting furnaces.Best Making A Melting Furnace Manufacturer has a global customer base and has established a reputation as a leading manufacturer of melting furnaces. The company provides high-quality products, excellent customer service, and technical support. The company's commitment to eco-friendly and energy-efficient products sets them apart from their competitors.In conclusion, Best Making A Melting Furnace Manufacturer is a leading manufacturer of high-quality melting furnaces. The company produces different types of furnaces that cater to different industries and provides excellent customer service and support. Best Making A Melting Furnace Manufacturer's commitment to eco-friendly products and custom solutions sets them apart from their competitors. With their global customer base and reputation, Best Making A Melting Furnace Manufacturer is an excellent choice for those in need of melting furnaces. So, it can be a great choice for entrepreneurs looking to venture into manufacturing businesses.

Top Large Melting Furnace Manufacturers to Consider for Your Business

As the demand for large melting furnaces continues to increase in various industries such as metal casting, automotive, and aerospace, the need for high-quality and efficient melting furnace manufacturers has become paramount. In this article, we will introduce the best large melting furnace manufacturers and provide an overview of their company profile.One of the leading manufacturers in the large melting furnace industry is {}, a company with a strong reputation for producing top-quality furnaces designed for melting a wide range of materials including aluminum, steel, and copper. With a global presence and a commitment to innovation and customer satisfaction, {} has positioned itself as a leader in the market.The company's melting furnaces are known for their advanced technology, energy efficiency, and robust construction. With a focus on meeting the diverse needs of its customers, {} offers a wide range of melting furnace solutions, including induction furnaces, electric arc furnaces, and gas-fired furnaces. These furnaces are designed to deliver high performance, precise temperature control, and consistent melting capabilities, making them suitable for a wide range of industrial applications.In addition to its cutting-edge products, {} provides comprehensive support and services to its customers, including installation, maintenance, and technical assistance. This commitment to customer satisfaction has earned {} a loyal customer base and a strong reputation within the industry.Another key player in the large melting furnace market is {}, a company known for its expertise in providing custom-designed melting furnace solutions for various industrial applications. With a focus on innovation and precision engineering, {} has established itself as a reliable partner for businesses seeking high-performance melting furnace technology.{}'s melting furnaces are designed to meet the specific needs of its customers, offering advanced features such as rapid heating and cooling cycles, precise temperature control, and energy-efficient operation. Whether it's for melting steel, iron, or non-ferrous metals, {}'s furnaces are designed to deliver consistent and reliable performance.In addition to its product offerings, {} provides a range of support services to its customers, including technical consulting, installation, and training. With a strong emphasis on customer satisfaction, {} has built a solid reputation for delivering top-quality products and services to its clients.Furthermore, with the growing emphasis on sustainability and environmental responsibility, {} has also developed melting furnace solutions that prioritize energy efficiency and emission reduction. By integrating advanced technologies and sustainable practices into its products, {} is at the forefront of promoting green and environmentally friendly melting furnace solutions for the industry.Last but not least, {} is also a prominent player in the large melting furnace market. The company's expertise in providing high-quality and reliable melting furnace solutions has earned it a strong reputation in the industry. With a focus on technological innovation and customer satisfaction, {} continues to be a top choice for businesses seeking advanced melting furnace technology.{}'s melting furnaces are designed to meet the demanding requirements of modern industrial applications, offering features such as rapid melting cycles, precise temperature control, and energy-efficient operation. Whether it's for melting ferrous or non-ferrous metals, {}'s furnaces are engineered to deliver exceptional performance and reliability.Furthermore, {} takes pride in its customer-centric approach, offering comprehensive support services to its clients, including installation, maintenance, and technical assistance. By prioritizing the needs of its customers, {} has established long-term partnerships with businesses across various industries.In conclusion, the demand for high-quality large melting furnaces continues to grow, and manufacturers such as {}, {}, and {} are at the forefront of meeting this demand. With their advanced technology, commitment to innovation, and customer-centric approach, these companies have earned their reputation as the best large melting furnace manufacturers in the industry. Whether it's for melting steel, aluminum, or other materials, businesses can rely on these manufacturers to deliver top-quality melting furnace solutions for their industrial needs.

Top Induction Heater Crucible Manufacturers in China

China is known for its manufacturing prowess and the induction heater crucible industry is no exception. With a rapidly growing economy and a focus on innovation and technology, Chinese induction heater crucible manufacturers are making waves in the global market.One such manufacturer, {}, has been at the forefront of this industry for many years. Specializing in the production of high-quality induction heater crucibles, they have gained a reputation for their commitment to excellence and customer satisfaction.Established in the heart of China's manufacturing hub, {} has access to state-of-the-art facilities and a skilled workforce. This has allowed them to consistently produce top-of-the-line induction heater crucibles that meet the highest industry standards.As a leading manufacturer, {} offers a wide range of induction heater crucibles to meet the diverse needs of their global customer base. From small-scale operations to large industrial applications, their products are designed to deliver superior performance and durability.One of the key factors that sets {} apart from other manufacturers is their dedication to research and development. They have a team of experienced engineers and technicians who are constantly working on improving their products and developing new technologies to stay ahead of the competition.In addition to their commitment to product quality, {} also places a strong emphasis on environmental sustainability. They have implemented eco-friendly practices in their manufacturing processes to minimize their impact on the environment, and they are constantly striving to improve their sustainability efforts.Another important aspect of {}'s success is their customer-centric approach. They understand the unique needs of their clients and work closely with them to provide tailored solutions that meet their specific requirements. This has helped them build long-term relationships with customers around the world.With their dedication to innovation, quality, and customer satisfaction, {} has quickly become a trusted name in the induction heater crucible industry. Their products are widely used in various sectors, including metal smelting, casting, and heat treatment, and they have earned a solid reputation for their reliability and performance.The global demand for induction heater crucibles is on the rise, and {} is well-positioned to capitalize on this trend. They have a strong presence in both domestic and international markets, and they are constantly exploring new opportunities to expand their reach and strengthen their position in the industry.As the global market for induction heater crucibles continues to grow, {} is poised to play a key role in shaping the future of this industry. With their unwavering commitment to excellence and innovation, they are well-equipped to meet the evolving needs of their customers and drive the industry forward.

Top Copper Scrap Melting Furnace Manufacturers

Title: Prominent Copper Scrap Melting Furnace Manufacturers Emerge in the MarketIntroduction:The growing demand for copper, coupled with the emphasis on sustainable practices, has fueled the need for advanced technology in the recycling industry. Leading manufacturers are stepping up to meet this demand by developing innovative copper scrap melting furnaces. With a focus on energy efficiency, productivity, and environmental conservation, these manufacturers are revolutionizing the copper recycling industry. This article will highlight some of the best copper scrap melting furnace manufacturers who are making significant strides in the market.1. Company A:Company A has emerged as a force to be reckoned with in the copper scrap melting furnace market. Utilizing state-of-the-art technology, their furnaces are designed to maximize energy efficiency while minimizing emissions. The company's commitment to sustainable practices is evident through their incorporation of advanced filtration systems, resulting in reduced air pollution.With a strong track record in the industry, the company has earned a solid reputation for producing reliable and durable copper scrap melting furnaces. Moreover, Company A places a strong emphasis on customer satisfaction by offering comprehensive customer support and maintenance services, ensuring seamless operations for their clientele.2. Company B:Company B prides itself on its ability to offer tailored solutions to meet specific customer requirements. Their copper scrap melting furnaces are customizable, allowing businesses to optimize their operations to suit their specific needs. Recognizing the importance of efficiency and cost-effectiveness, Company B has incorporated cutting-edge technology into their designs to enhance productivity while minimizing energy consumption.The company's commitment to quality is further reflected in their attention to detail during the manufacturing process. Each furnace undergoes rigorous testing, ensuring that only top-notch products reach the market. Customer feedback plays a significant role in their continuous improvement strategy, allowing Company B to constantly innovate and enhance their offerings.3. Company C:Company C sets itself apart by combining years of experience with a commitment to sustainability. Their copper scrap melting furnaces are designed to exceed industry standards, utilizing advanced features such as intelligent automation and accurate temperature control. This results in optimized energy consumption and reduced waste generation during the melting process.The company's expertise in energy management and emissions control ensures compliance with environmental regulations. Additionally, Company C focuses on continuous research and development, incorporating the latest technological advancements into their products. This allows customers to benefit from enhanced efficiency, reduced downtime, and improved operational control.4. Company D:Company D has established a strong presence in the copper scrap melting furnace market by prioritizing customer-centric solutions. Their furnaces are engineered to deliver exceptional performance, catering to a broad range of customer requirements. By adopting a holistic approach, virtual simulations enable the company to offer innovative designs that optimize melting efficiency.Additionally, Company D offers comprehensive after-sales support, including installation, training, and maintenance services. Their commitment to service excellence has garnered them a loyal customer base and positioned them as a reliable partner in the copper recycling industry.Conclusion:The copper scrap melting furnace market has witnessed significant advancements from prominent manufacturers. Companies A, B, C, and D have demonstrated their commitment to sustainability, energy efficiency, and customer satisfaction. By offering innovative and customizable solutions, these manufacturers are leading the way in revolutionizing the copper recycling industry. With continued investment in research and development, these companies are sure to shape the future of copper scrap melting furnaces, further contributing to the circular economy.

Top Manufacturer for Induction Furnace Cooling Systems Revealed

piece:Induction Furnace Cooling System: The Secret Behind Efficient Metal MeltingInduction furnaces are among the most innovative and effective ways of melting metals, and they operate by using electromagnetic induction to heat up and melt metals. Unlike traditional furnaces that rely on heating elements, induction furnaces produce heat through electromagnetic currents, making them more efficient, faster, and safer than their conventional counterparts.However, as with most advanced technologies, they come with a few maintenance challenges. One of the most significant challenges is maintaining the ideal operating temperature through the efficient cooling of the system. If an induction furnace's temperature exceeds the recommended levels, it can cause severe damage to the furnace, resulting in costly repairs or even machine replacement.To prevent this from happening, induction furnace manufacturers need to integrate the best cooling systems, preferably those from a reliable cooling system manufacturer, to ensure optimal furnace performance.For those in search of the best induction furnace cooling system manufacturer, look no further than the leading cooling system company. The company is a global player in the cooling system industry, with a reputation for designing and manufacturing innovative and high-quality cooling systems for various industrial applications.The company's induction furnace cooling systems are designed to provide a reliable, stable, efficient, and cost-effective cooling solution for all types of furnaces, including induction furnaces. They provide the necessary cooling capacity, whether for continuous or intermittent operations, ensuring prolonged furnace life, enhanced performance, and increased productivity.One of the most significant advantages of the company's induction furnace cooling systems is their energy efficiency. The cooling systems are designed to operate with lower power consumption while still maintaining optimal cooling capacity. This translates to lower energy bills and reduced carbon footprint, which is excellent news for environmentally conscious furnace operators.In addition to their energy efficiency, the cooling systems are designed for ease of installation and maintenance, thanks to the modular design and user-friendly interface. The company's commitment to excellent customer service means that they provide comprehensive pre and post-installation support to customers, including on-site installation and training, and remote troubleshooting and maintenance services.The company's induction furnace cooling systems have proven reliability, having been subjected to rigorous testing and inspection before release to the market. They are made from the highest quality materials and components, ensuring durability, functionality, and performance consistency.The company's cooling systems feature cutting-edge technologies, such as intelligent temperature control, real-time monitoring, and automatic adjustment of cooling capacity. These technologies prevent overheating, drastic temperature changes, and other furnace malfunctions that could cause damage to the equipment or the melted metals.In conclusion, induction furnaces are an excellent option for industrial metal melting applications, and the cooling system is a crucial component to ensure optimal furnace performance. While several induction furnace cooling system manufacturers are available in the market, the leading cooling system company stands out from the crowd for their energy efficiency, reliability, durability, and functionality. Their induction furnace cooling systems provide a reliable and efficient cooling solution for all furnace types while ensuring extended furnace life, productivity, and enhanced performance. Contact the company today for a bespoke induction furnace cooling system to suit your furnace's unique needs.