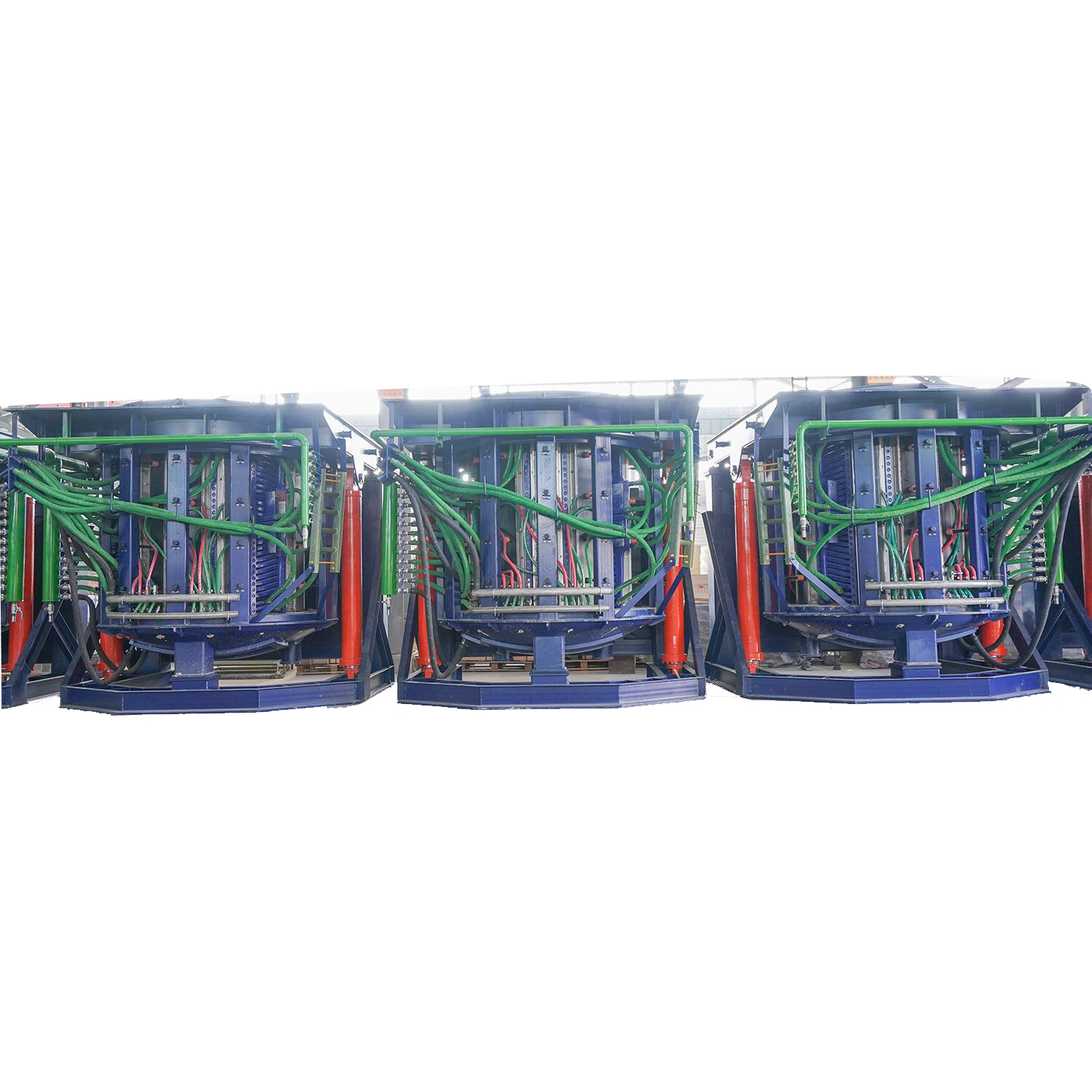

Top Auto Melting Furnace for Efficient Melting Operations

By:Admin

The metal industry has been continuously evolving with the advancement of technology and machinery. The introduction of the Auto Melting Furnace by {Company Name} has marked a significant milestone in the industry, revolutionizing the way metal is melted and processed. This state-of-the-art melting furnace is designed to provide efficiency, precision, and reliability, making it the go-to choice for metal manufacturers and foundries worldwide.

{Company Name} has always been at the forefront of innovation and excellence in the manufacturing industry. With a dedicated team of engineers and experts, they have been consistently developing cutting-edge solutions to meet the demands of the modern metal industry. Their Auto Melting Furnace is a testament to their commitment to excellence and their understanding of the needs of their customers.

The Auto Melting Furnace is equipped with advanced technology and features that set it apart from traditional melting furnaces. One of its key highlights is its automated operation, which eliminates the need for manual intervention during the melting process. This not only saves time and labor costs but also ensures a higher level of precision and consistency in the melting process.

In addition to its automation, the furnace is also equipped with advanced temperature control and monitoring systems. This allows for precise control of the melting process, ensuring that the metal is melted at the optimal temperature and in a uniform manner. The result is a higher quality of molten metal, which translates to better quality end products for manufacturers.

Furthermore, the Auto Melting Furnace is designed for energy efficiency, helping companies reduce their energy consumption and operating costs. This is achieved through its innovative design and insulation, which minimizes heat loss and maximizes the efficiency of the melting process. As a result, companies can expect a significant reduction in their energy bills while maintaining high productivity levels.

The reliability of the furnace is another key factor that sets it apart. {Company Name} has built a strong reputation for producing durable and reliable machinery, and the Auto Melting Furnace is no exception. Its robust construction and high-quality components ensure that it can withstand the rigors of continuous operation, making it a dependable and long-lasting investment for metal manufacturers.

Furthermore, the furnace is designed for easy maintenance and servicing, minimizing downtime and ensuring that it remains in optimal working condition at all times. This is crucial for companies that rely on continuous production and cannot afford prolonged equipment downtime.

{Company Name} also provides comprehensive support and service for the Auto Melting Furnace, including installation, training, and ongoing technical support. This ensures that customers can maximize the benefits of the furnace and address any issues or concerns promptly.

The introduction of the Auto Melting Furnace by {Company Name} has been met with enthusiasm and positive feedback from the industry. Metal manufacturers and foundries are eager to adopt this advanced technology to enhance their production processes and stay ahead of the competition.

In conclusion, the Auto Melting Furnace by {Company Name} represents a significant advancement in metal melting technology. Its combination of automation, precision, energy efficiency, and reliability makes it the best choice for metal manufacturers looking to optimize their melting processes and improve the quality of their end products. With the support and expertise of {Company Name}, customers can expect to achieve new levels of efficiency and productivity in their operations.

For more information on the Auto Melting Furnace and other innovative solutions by {Company Name}, please visit their website or contact their sales team.

Company News & Blog

Top Electric Metal Melting Furnace for Efficient Metal Melting Operations

The electric metal melting furnace is an essential piece of equipment for many industries that rely on the melting and casting of metal. Whether it's for creating intricate jewelry pieces, manufacturing industrial parts, or crafting custom-designed metal sculptures, the electric metal melting furnace plays a crucial role in the production process.One of the leading companies in the field of electric metal melting furnaces is {Company Name}. With a strong focus on innovation and advanced technology, {Company Name} has established itself as a reliable and trusted provider of high-quality electric metal melting furnaces.{Company Name} offers a wide range of electric metal melting furnaces that are designed to meet the diverse needs of their customers. Whether it's a small, compact furnace for a jewelry workshop or a larger, more powerful furnace for an industrial facility, {Company Name} has the expertise and experience to provide the right solution.One of the key features of {Company Name}'s electric metal melting furnaces is their efficiency and reliability. The furnaces are built to withstand high temperatures and long hours of operation, ensuring consistent and uniform melting of the metal. This not only improves the quality of the final product but also enhances the overall productivity of the manufacturing process.In addition to their durability, {Company Name}'s electric metal melting furnaces are also designed with safety in mind. The furnaces are equipped with advanced safety features to prevent accidents and ensure the well-being of the operators. This attention to safety further demonstrates {Company Name}'s commitment to providing top-quality products that prioritize both performance and the welfare of their customers.Furthermore, {Company Name} takes pride in their commitment to environmental sustainability. Their electric metal melting furnaces are designed to minimize energy consumption and reduce carbon emissions, making them an eco-friendly choice for businesses looking to minimize their environmental impact. This aligns with {Company Name}'s overarching goal of promoting sustainable manufacturing practices and contributing to a greener, more eco-conscious industry.The electric metal melting furnaces offered by {Company Name} are also known for their user-friendly design and ease of operation. With intuitive controls and clear instructions, operators can easily manage the melting process with confidence and precision. This user-focused approach reflects {Company Name}'s dedication to providing a seamless and efficient experience for their customers.In addition to their exceptional products, {Company Name} also provides comprehensive customer support services to ensure that their clients receive ongoing assistance and guidance. From installation and training to maintenance and troubleshooting, {Company Name} stands by their customers every step of the way, guaranteeing a positive and successful experience with their electric metal melting furnaces.The success and reputation of {Company Name} in the industry can be attributed to their unwavering dedication to excellence and their relentless pursuit of innovation. By continuously pushing the boundaries of technology and manufacturing, {Company Name} has positioned itself as a leading provider of electric metal melting furnaces, setting the standard for reliability, performance, and customer satisfaction.With their continued commitment to quality and customer-centric approach, {Company Name} is poised to remain a dominant force in the market, driving the advancement of electric metal melting furnace technology and helping businesses around the world achieve their production goals with confidence and ease.

Efficient Induction Furnace for Industrial Heating Processes

Induction Furnace Technology Revolutionizing the Manufacturing IndustryIn the fast-paced world of manufacturing, the need for efficient and reliable equipment is of utmost importance. Companies are constantly seeking new technologies and innovations to increase productivity and reduce costs. One such technology that has been revolutionizing the manufacturing industry is induction furnace technology.Induction furnaces utilize the principle of induction heating to melt metals. This technology has become increasingly popular in the manufacturing sector due to its numerous advantages over traditional methods of metal melting. The efficiency and precision of induction furnaces make them an essential tool for companies involved in metal melting and casting.One company that has been leading the way in the development and production of induction furnaces is Indotherm. Since its inception, Indotherm has been at the forefront of innovation in the field of induction heating technology. The company has a rich history of providing cutting-edge solutions to the manufacturing industry, and its induction furnaces are no exception.Indotherm's induction furnaces are designed to provide unmatched performance and reliability. They are capable of melting a wide range of metals, including steel, iron, copper, and aluminum, making them suitable for a variety of manufacturing applications. The company's commitment to quality and innovation has made its induction furnaces highly sought after by manufacturers around the world.Indotherm's induction furnaces are known for their energy efficiency and environmental sustainability. Unlike traditional methods of metal melting, induction furnaces do not rely on fossil fuels for heating. Instead, they use electromagnetic induction to generate heat, resulting in significantly lower energy consumption and carbon emissions. This makes them an attractive option for companies looking to reduce their environmental footprint while improving their bottom line.Furthermore, Indotherm's induction furnaces offer unparalleled precision and control. The advanced technology incorporated into these furnaces allows for precise temperature control and uniform heating, resulting in high-quality metal melts. This level of precision is essential for manufacturing processes that require exacting standards, such as the production of automotive parts, aerospace components, and industrial machinery.Indotherm's induction furnaces are also designed with ease of use and maintenance in mind. The company's commitment to customer satisfaction is evident in the user-friendly interfaces and robust construction of its furnaces. Additionally, Indotherm provides comprehensive technical support and maintenance services to ensure that its customers can maximize the performance and lifespan of their induction furnaces.The widespread adoption of induction furnace technology is a testament to its significant impact on the manufacturing industry. Manufacturers who have embraced this technology have seen improvements in production efficiency, product quality, and cost savings. Indotherm's induction furnaces have played a crucial role in enabling these advancements, making them a valuable asset for companies looking to stay competitive in today's market.In conclusion, induction furnace technology has revolutionized the manufacturing industry, and companies like Indotherm have been at the forefront of this revolution. With their innovative and reliable induction furnaces, Indotherm has helped countless manufacturers achieve higher levels of efficiency, sustainability, and performance. As the demand for induction furnace technology continues to grow, it is clear that Indotherm will remain a key player in shaping the future of manufacturing.

Guide to Induction Steel Melting: Process, Benefits, and Applications

Induction Steel Melting Technology Revolutionizes Steel Production: A closer look at the innovative process at [company name]In the fast-paced world of steel production, advancements in technology and innovation are constantly reshaping the industry. One such revolutionary development is the introduction of Induction Steel Melting technology, which has been making waves in the steel manufacturing sector. This groundbreaking process has the potential to transform the way steel is produced, making it more efficient, sustainable, and cost-effective.One of the companies at the forefront of this technological revolution is [company name]. With a rich history of expertise and experience in the steel manufacturing industry, [company name] has been a driving force behind the implementation of Induction Steel Melting technology. The company has embraced this innovative approach as part of its commitment to staying at the cutting edge of steel production, and as a response to the growing demand for more sustainable and environmentally friendly manufacturing processes.Induction Steel Melting technology represents a significant departure from traditional steel production methods, such as the use of blast furnaces. Instead of relying on fossil fuels and producing large amounts of greenhouse gas emissions, this new process utilizes electromagnetic induction to heat and melt steel scrap. This results in a more energy-efficient and environmentally friendly method of steel production, with reduced carbon emissions and lower energy consumption.The induction melting process begins with the collection of steel scrap, which is then loaded into the furnace for melting. Once inside the furnace, an electromagnetic field is generated, causing the steel to heat up and melt without direct contact with any heating elements. This not only speeds up the melting process but also ensures a more uniform and controlled heating of the steel, leading to higher quality end products.One of the key advantages of Induction Steel Melting technology is its versatility. Unlike traditional steel production methods, which are often limited in the types of steel that can be produced, induction melting allows for the production of a wide range of steel grades, including specialty alloys. This flexibility makes it an attractive option for manufacturers looking to diversify their product offerings and meet the evolving needs of their customers.Furthermore, the induction melting process is highly efficient, with minimal material wastage and lower energy consumption compared to traditional methods. This not only contributes to cost savings for manufacturers but also reduces the environmental impact of steel production. Additionally, the use of steel scrap as the primary raw material further enhances the sustainability of this process by reducing the reliance on virgin materials and minimizing waste.[company name] has fully embraced the potential of Induction Steel Melting technology and has made significant investments in implementing this innovative process across its manufacturing facilities. By integrating this cutting-edge technology into their operations, the company has demonstrated its commitment to sustainability, efficiency, and quality in steel production. As a result, [company name] has positioned itself as a leader in the industry, setting new standards for responsible and forward-thinking manufacturing practices.Looking ahead, the widespread adoption of Induction Steel Melting technology is poised to revolutionize the steel manufacturing sector, offering a more sustainable, cost-effective, and efficient alternative to traditional production methods. As more companies follow in the footsteps of innovators like [company name], the industry as a whole stands to benefit from reduced environmental impact, improved product quality, and enhanced competitiveness on the global stage. With Induction Steel Melting technology leading the way, the future of steel production is looking brighter than ever.

Highly Efficient Metal Induction Furnace for Industrial Use

Metal Induction Furnace Revolutionizes Manufacturing IndustryIn today's fast-paced, high-demand manufacturing industry, companies are constantly seeking ways to improve efficiency and productivity. One of the most important developments in recent years has been the introduction of metal induction furnaces. These state-of-the-art furnaces have revolutionized the way metals are melted and processed, leading to significant improvements in manufacturing processes across various industries.One of the leading companies at the forefront of this innovation is {}. With decades of experience and expertise in the manufacturing industry, {} has successfully developed and introduced the most advanced metal induction furnace technology to the market. This cutting-edge technology has had a profound impact on the manufacturing industry, offering a wide range of benefits to companies looking to enhance their productivity and operational efficiency.The metal induction furnace, developed by {}, operates on the principle of electromagnetic induction, which allows for precise control over the melting process. Unlike traditional furnaces that rely on direct heat, induction furnaces use electromagnetic currents to heat the metal, resulting in faster and more efficient melting. This technology also allows for the precise control of temperature and heat distribution, leading to higher quality output with minimal material wastage.One of the key advantages of the metal induction furnace is its ability to melt a wide range of metals, including steel, iron, copper, and aluminum, among others. This versatility makes it an indispensable tool for manufacturing companies that work with various types of metals. Moreover, the induction furnace is capable of melting smaller batches of metal, which is particularly beneficial for companies that require precise control over their production processes.Furthermore, the metal induction furnace developed by {} is designed with advanced safety features to ensure a secure working environment. With automatic shutdown mechanisms and advanced cooling systems, the risk of accidents and equipment damage is greatly reduced, providing peace of mind for manufacturing companies and their employees.The impact of the metal induction furnace on the manufacturing industry has been nothing short of revolutionary. Companies that have adopted this technology have reported significant improvements in their operational efficiency, reduced energy consumption, and lower production costs. By streamlining the production process and minimizing material wastage, the induction furnace has contributed to a more sustainable and environmentally friendly approach to manufacturing.With a proven track record of innovation and excellence, {} has become a trusted partner for manufacturing companies seeking to incorporate the latest advancements in technology into their operations. The company's commitment to research and development has allowed them to stay ahead of the curve and deliver cutting-edge solutions that address the evolving needs of the manufacturing industry.In addition to the metal induction furnace, {} offers a comprehensive range of services, including installation, maintenance, and technical support. Their team of experts is dedicated to providing personalized solutions and guidance to help manufacturing companies maximize the benefits of this groundbreaking technology.Looking ahead, the future of manufacturing will undoubtedly be shaped by advancements in technology, and the metal induction furnace is poised to play a pivotal role in this evolution. As the demand for high-quality, efficient, and sustainable manufacturing processes continues to grow, companies like {} will continue to lead the way with their innovative solutions and unwavering commitment to excellence.In conclusion, the introduction of the metal induction furnace has transformed the manufacturing industry, offering a wide range of benefits, from improved operational efficiency to reduced costs and environmental impact. With its cutting-edge technology and commitment to excellence, {} has established itself as a leading provider of advanced solutions for the manufacturing industry, and their metal induction furnace is poised to revolutionize the way metals are melted and processed for years to come.

Best Supplier for Induction Furnace Frequencies

Induction furnaces have revolutionized the world of metallurgy and manufacturing, providing a highly efficient and cost-effective alternative to traditional methods of melting and pouring metal. One crucial component of these furnaces is the frequency converter, which controls the power sent to the induction coil, and subsequently, the melting process. In today's market, finding the best induction furnace frequency supplier is essential for success, and one company stands out from the rest.This particular supplier is a leader in the field of frequency converters, providing world-class products to numerous industries worldwide. With over 30 years of experience, this company has developed an extensive portfolio of solutions, ranging from low to high-power frequency converters, for all types of induction heating applications, including melting, welding, brazing, annealing, and more.Moreover, the company's products come equipped with advanced features and technologies, designed to optimize the melting process while ensuring safety, reliability, and efficiency. Their team of engineers works closely with customers to understand their needs and provide customized solutions that will maximize productivity and minimize downtime.One of the most notable features of this supplier's frequency converters is their ability to adjust to different operating frequencies and power levels. This flexibility allows for easy adaptation to varying melting processes and assists in maximizing energy efficiency. Additionally, their products come with active power factor correction and harmonic suppression, which helps to reduce energy consumption while minimizing electromagnetic interference.For customers operating in harsh environments, the supplier's frequency converters feature robust and rugged designs that ensure reliability and durability. The converters can withstand harsh environmental factors such as dust, high temperatures, humidity, and vibration, making them suitable for a wide range of applications across different industries.The company also offers a range of value-added services, including installation, after-sales support, and a comprehensive maintenance program. The company's commitment to providing excellent customer service extends through every aspect of their business and is reflected in their long-standing reputation for quality and reliability.Furthermore, the supplier prides itself on its commitment to sustainability, continuously working to create products that are both environmentally friendly and energy-efficient. Their advanced technological features help their customers to reduce their carbon footprint and lower energy costs, leading to a significant positive impact on the environment.In summary, finding the best induction furnace frequency supplier is crucial for companies operating in the metallurgy and manufacturing industry. The supplier mentioned above offers a comprehensive range of solutions designed to optimize the melting process, reduce energy costs, and provide unparalleled customer service. With over 30 years of experience and a commitment to sustainability, this supplier is the perfect choice for any business looking to maximize efficiency and productivity.

Title: "Efficient and Eco-Friendly Lead Smelting Furnace for Optimal Results

Title: Innovations in Lead Smelting Technology Set to Revolutionize the IndustryIntroduction:Lead smelting is a crucial process in the manufacturing of various products. It involves extracting lead from its ores and transforming it into useful materials, such as batteries, ammunition, and x-ray shielding. Recently, a renowned company has unveiled its groundbreaking Lead Smelting Furnace, promising game-changing advancements in efficiency, environmental impact, and overall productivity. This revolutionary technology aims to transform the lead smelting industry, ensuring a sustainable future for both manufacturers and the environment.Background:Lead smelting has often faced scrutiny due to its hazardous environmental impact. Traditional furnaces emit high levels of toxic fumes, such as sulfur dioxide and lead particles, which pose severe health risks to workers and nearby communities. Recognizing the need for a safer and more sustainable alternative, the company has invested years of research and development to create the innovative Lead Smelting Furnace. Let's dive deeper into the features and benefits that this furnace brings to the industry.Improved Efficiency:The new Lead Smelting Furnace incorporates cutting-edge technology that enhances efficiency in multiple ways. The furnace's advanced control systems provide precise temperature regulation, optimizing energy consumption and reducing waste. The furnace's design also promotes better heat transfer, allowing for faster and more uniform melting of lead ores. These improvements result in higher productivity rates and substantial energy savings, boosting manufacturers' profitability while reducing their environmental footprint.Eco-Friendly Design:Recognizing the importance of environmental sustainability, the company has ensured that the new furnace significantly reduces harmful emissions. By incorporating state-of-the-art gas treatment and filtration systems, the furnace effectively captures and neutralizes harmful pollutants. This innovative design ensures that emissions of sulfur dioxide, lead particles, and other harmful substances are minimized, preserving air quality and safeguarding the health of both workers and surrounding communities.Safety and Worker Well-being:In addition to environmental benefits, the Lead Smelting Furnace prioritizes worker safety and well-being. The furnace's improved design minimizes exposure to hazardous materials, such as lead fumes and dust. It features advanced air filtration systems and state-of-the-art personal protective equipment for workers operating near the furnace. This ensures a healthier and safer working environment, reducing the risk of occupational health issues associated with lead smelting.Real-Time Monitoring and Automation:The Lead Smelting Furnace combines cutting-edge technology with automation to provide real-time monitoring and control. Integrated sensors and software systems continuously monitor temperature, pressure, and other critical parameters. This enables operators to detect and rectify potential issues promptly, minimizing downtime and optimizing production. Moreover, the furnace's automation capabilities streamline various processes, reducing human error and increasing overall production efficiency.Market Impact and Industry Benefits:The introduction of the Lead Smelting Furnace is expected to generate a significant positive impact on the lead smelting industry. Manufacturers will benefit from increased operational efficiency, reduced energy consumption, and lower maintenance costs. The heightened focus on sustainability will allow manufacturers to comply with strict environmental regulations and improve their corporate social responsibility image. Moreover, by prioritizing worker safety, the furnace will contribute to a more conducive and ethical working environment, attracting top talent and enhancing employee satisfaction.Conclusion:The unveiling of the revolutionary Lead Smelting Furnace promises to reshape the lead smelting industry. Through its enhanced efficiency, eco-friendly design, improved worker safety, and real-time monitoring capabilities, this innovative technology opens new avenues for sustainable and responsible manufacturing. Manufacturers can now achieve higher productivity levels while minimizing their environmental impact, ensuring a brighter future for both the industry and our planet.

Iron Melting Induction Furnace Manufacturer in China

China Iron Melting Induction Furnace Manufacturer Leads the Way in Innovation and Quality ProductionWith the ever-growing demand for iron and steel products in various industries, the need for efficient and high-quality iron melting induction furnaces has become increasingly important. In response to this demand, China-based (remove brand name) has emerged as a leading manufacturer of these furnaces, setting new standards in innovation and production quality.Established in (insert year), (remove brand name) has quickly grown to become a key player in the iron melting induction furnace industry. The company has built a strong reputation for its commitment to providing customers with reliable, energy-efficient, and cost-effective solutions for iron melting and casting processes. (Remove brand name) possesses a comprehensive range of products, including medium frequency induction furnaces, electric arc furnace transformers, and various other related equipment, all of which are designed to meet the diverse needs of their clients.What sets (remove brand name) apart from its competitors is its unwavering dedication to innovation and continuous improvement. The company invests heavily in research and development, constantly striving to enhance the performance, efficiency, and environmental sustainability of its products. By leveraging cutting-edge technology and advanced engineering techniques, (remove brand name) has been able to stay ahead of market trends and deliver state-of-the-art solutions to its customers.One of the most notable achievements of (remove brand name) is its development of a series of high-power, energy-efficient induction melting furnaces. These furnaces are equipped with advanced features such as automatic power control, digital temperature monitoring, and precise heat distribution, allowing for greater process control and enhanced productivity. In addition, (remove brand name) has also integrated smart automation systems into its furnaces, enabling operators to manage the entire melting process with ease and accuracy.Moreover, (remove brand name) takes great pride in its strict quality control measures, ensuring that every product that leaves its facilities adheres to the highest standards of performance and durability. The company’s state-of-the-art manufacturing facilities and testing laboratories are equipped with the latest machinery and equipment, enabling comprehensive quality assurance throughout the production process. As a result, customers can have full confidence in the reliability and longevity of (remove brand name)’s iron melting induction furnaces.In addition to its technological prowess and quality standards, (remove brand name) also places a strong emphasis on customer satisfaction and support. The company’s team of experienced engineers and technicians provide personalized consultation and technical assistance to clients, helping them select the most suitable furnace models and optimize their operational efficiency. Furthermore, (remove brand name) offers comprehensive after-sales services, including installation, maintenance, and repair, ensuring that its customers can enjoy uninterrupted and trouble-free performance of their equipment.Looking ahead, (remove brand name) is committed to furthering its position as a leader in the iron melting induction furnace industry. The company is continuously exploring new avenues for advancements in furnace design, efficiency, and environmental sustainability, with the ultimate goal of driving greater value for its customers. By fostering partnerships with industry stakeholders and staying attuned to the evolving needs of the market, (remove brand name) is poised to continue its trajectory of success and contribute to the advancement of iron and steel production worldwide.In conclusion, (remove brand name) has demonstrated exemplary leadership in the iron melting induction furnace manufacturing sector, standing out for its dedication to innovation, product quality, and customer satisfaction. As the demand for iron and steel products continues to rise, (remove brand name) is well-positioned to play a pivotal role in meeting the industry’s evolving needs, ushering in a new era of efficiency and reliability in iron melting and casting processes.

Quality Vacuum Induction Suppliers for industrial needs

Vacuum Induction Suppliers, a leading provider of vacuum induction melting and casting systems, has recently announced the launch of their newest product line. With a focus on innovation and cutting-edge technology, the company aims to deliver high-quality solutions for the metal casting industry.The company has been at the forefront of the industry for over 30 years, and their expertise in vacuum induction melting and casting has made them a preferred supplier for many global manufacturers. With a strong commitment to research and development, Vacuum Induction Suppliers has continuously pushed the boundaries of what is possible in metal casting technology.The new product line is the result of years of research and development, and it promises to deliver even greater performance and efficiency for their customers. With a focus on precision and reliability, the new systems are designed to meet the demands of the modern metal casting industry.One of the key features of the new product line is its advanced control system, which allows for precise monitoring and adjustment of the melting and casting process. This level of control not only ensures consistent quality in the final product, but also contributes to improved energy efficiency and reduced waste.In addition to the advanced control system, the new product line also includes enhancements to the overall design and construction of the systems. These improvements are aimed at increasing durability and reducing maintenance requirements, ultimately leading to lower operating costs and increased uptime for their customers.The launch of the new product line is a reflection of Vacuum Induction Suppliers' commitment to continuous improvement and innovation. By staying ahead of the curve with their technology, the company is positioning itself as a reliable and forward-thinking partner for the metal casting industry.In a statement, the company's CEO expressed their excitement about the new product line, stating, "We are proud to introduce our latest advancements in vacuum induction melting and casting technology. Our team has worked tirelessly to bring these new systems to market, and we are confident that they will set a new standard for performance and quality in the industry."The company's dedication to delivering high-quality solutions has earned them a strong reputation in the industry, and their customer base continues to grow as a result. With a focus on providing exceptional service and support, Vacuum Induction Suppliers has built long-lasting relationships with their customers, who rely on them for their expertise and reliability.As the metal casting industry continues to evolve, Vacuum Induction Suppliers remains committed to staying at the forefront of technological advancements. By investing in research and development, the company is well-positioned to meet the changing needs of their customers and to provide innovative solutions that drive the industry forward.With the launch of their new product line, Vacuum Induction Suppliers is sending a clear message to the industry: they are dedicated to pushing the boundaries of what is possible in metal casting technology, and they will continue to deliver cutting-edge solutions for their customers. As the company looks to the future, it remains focused on maintaining its position as a leader in the industry and providing unparalleled value to its customers.

Innovative Electric Melting Solutions for Manufacturers

Electric Melting Manufacturer (EMM) is a leading company in the field of electric melting technology, providing innovative and efficient solutions for the metal melting industry. With a focus on sustainability and advanced technology, EMM has established itself as a reliable partner for various industries that require precise and reliable melting solutions.The company has a rich history of innovation and expertise, with a team of highly skilled engineers and professionals who are dedicated to pushing the boundaries of electric melting technology. EMM’s commitment to research and development has led to the creation of cutting-edge melting solutions that are not only cost-effective but also environmentally friendly.One of EMM’s most notable achievements is its development of electric arc furnaces that utilize advanced control systems to optimize energy consumption and reduce emissions. These furnaces are capable of melting a wide range of metals, including steel, iron, and aluminum, with unparalleled efficiency and precision. By incorporating state-of-the-art technologies such as regenerative burner systems and advanced refractory materials, EMM has been able to push the boundaries of electric melting technology, setting new industry standards for performance and sustainability.In addition to its innovative melting solutions, EMM also offers comprehensive technical support and after-sales services to ensure that its clients are able to maximize the value of their investment. The company’s team of experts is available to provide on-site assistance, preventative maintenance, and training programs to help clients achieve optimal performance and efficiency.With a strong focus on customer satisfaction and continuous improvement, EMM has earned a reputation for reliability and excellence in the field of electric melting technology. The company’s commitment to quality and innovation has led to partnerships with a wide range of industry leaders, further solidifying its position as a trusted provider of melting solutions.In recent news, EMM has announced the launch of its newest electric melting technology, the EMM-7000 series. This series represents a significant leap forward in electric melting technology, featuring advanced control systems and innovative materials that deliver unprecedented performance and efficiency. The EMM-7000 series is designed to meet the growing demand for sustainable and cost-effective melting solutions, offering a range of models with varying capacities to suit the specific needs of different industries.“We are proud to introduce the EMM-7000 series, which represents the culmination of years of research and development,” said the CEO of EMM. “With this new technology, we aim to empower our clients with the tools they need to achieve greater efficiency, sustainability, and profitability in their operations. We believe that the EMM-7000 series will set a new standard for electric melting technology and further solidify our position as a leader in the industry.”The launch of the EMM-7000 series comes at a time of growing demand for sustainable and efficient melting solutions, driven by increasing environmental regulations and a growing awareness of the need for responsible industrial practices. EMM’s commitment to sustainability and innovation has positioned the company as a key player in this space, with its electric melting technology playing a vital role in helping industries reduce their environmental footprint and improve their overall efficiency.As EMM continues to push the boundaries of electric melting technology, the company remains focused on its mission of delivering value to its clients through cutting-edge solutions and unparalleled service. With a track record of success and a commitment to excellence, EMM is well-positioned to lead the way in shaping the future of electric melting technology.

Top Copper Scrap Melting Furnace Manufacturers: Find the Best Option for Your Business

The demand for high-quality copper scrap melting furnaces is on the rise, and manufacturers are continuously striving to meet the industry's needs. One of the leading companies in the manufacturing of these furnaces is {}.{} is a renowned manufacturer of copper scrap melting furnaces that are known for their efficiency, reliability, and durability. The company has been in the industry for several decades and has a solid reputation for delivering high-quality products to its customers.The company's furnace is designed to efficiently melt copper scrap and produce high-quality molten copper that can be used for various applications. It is equipped with advanced technology and features that ensure optimal performance and cost-effective operations.One of the key factors that set {} apart from its competitors is its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay ahead of the curve and offer cutting-edge solutions to its customers.Furthermore, {} prides itself on its strong focus on customer satisfaction. The company understands the unique needs of its clients and works closely with them to provide customized solutions that meet their specific requirements. With a team of experienced and skilled engineers, {} is able to deliver tailored products and services that exceed customer expectations.In addition to its commitment to quality and innovation, {} is also dedicated to sustainability and environmental responsibility. The company's furnace is designed to minimize energy consumption and emissions, making it an eco-friendly choice for businesses looking to reduce their carbon footprint.{} has a global presence and serves clients in various industries, including metal fabrication, copper recycling, and manufacturing. Its furnaces are trusted by businesses around the world for their superior performance and long-term reliability.The company's success can be attributed to its strong leadership, dedicated workforce, and cutting-edge technology. With a focus on continuous improvement and customer satisfaction, {} is well-positioned to maintain its status as one of the best copper scrap melting furnace manufacturers in the industry.As the demand for high-quality copper scrap melting furnaces continues to grow, {} remains at the forefront of innovation and excellence. The company's commitment to delivering superior products and services sets it apart as a leader in the industry, and its dedication to sustainability and customer satisfaction makes it a trusted partner for businesses worldwide.In conclusion, {} is a top-tier manufacturer of copper scrap melting furnaces, offering efficient, reliable, and cost-effective solutions to businesses in various industries. With a focus on innovation, customer satisfaction, and sustainability, the company is well-equipped to meet the evolving needs of the industry and maintain its position as a leader in the market. Businesses looking for high-quality copper scrap melting furnaces can trust {} to provide them with top-notch products and exceptional service.