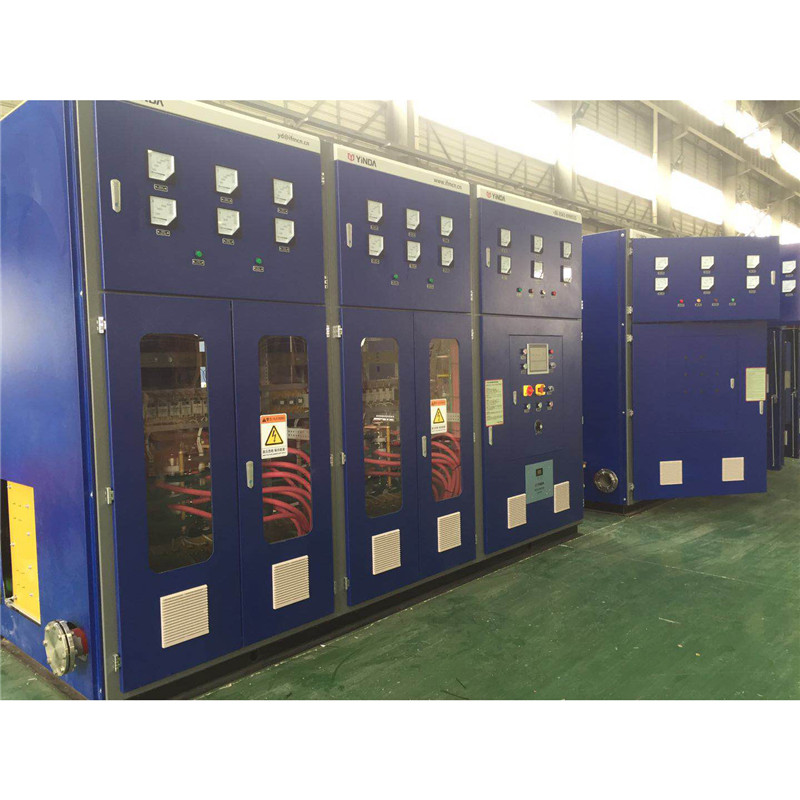

Efficient Induction Furnace for Industrial Heating Processes

By:Admin

In the fast-paced world of manufacturing, the need for efficient and reliable equipment is of utmost importance. Companies are constantly seeking new technologies and innovations to increase productivity and reduce costs. One such technology that has been revolutionizing the manufacturing industry is induction furnace technology.

Induction furnaces utilize the principle of induction heating to melt metals. This technology has become increasingly popular in the manufacturing sector due to its numerous advantages over traditional methods of metal melting. The efficiency and precision of induction furnaces make them an essential tool for companies involved in metal melting and casting.

One company that has been leading the way in the development and production of induction furnaces is Indotherm. Since its inception, Indotherm has been at the forefront of innovation in the field of induction heating technology. The company has a rich history of providing cutting-edge solutions to the manufacturing industry, and its induction furnaces are no exception.

Indotherm's induction furnaces are designed to provide unmatched performance and reliability. They are capable of melting a wide range of metals, including steel, iron, copper, and aluminum, making them suitable for a variety of manufacturing applications. The company's commitment to quality and innovation has made its induction furnaces highly sought after by manufacturers around the world.

Indotherm's induction furnaces are known for their energy efficiency and environmental sustainability. Unlike traditional methods of metal melting, induction furnaces do not rely on fossil fuels for heating. Instead, they use electromagnetic induction to generate heat, resulting in significantly lower energy consumption and carbon emissions. This makes them an attractive option for companies looking to reduce their environmental footprint while improving their bottom line.

Furthermore, Indotherm's induction furnaces offer unparalleled precision and control. The advanced technology incorporated into these furnaces allows for precise temperature control and uniform heating, resulting in high-quality metal melts. This level of precision is essential for manufacturing processes that require exacting standards, such as the production of automotive parts, aerospace components, and industrial machinery.

Indotherm's induction furnaces are also designed with ease of use and maintenance in mind. The company's commitment to customer satisfaction is evident in the user-friendly interfaces and robust construction of its furnaces. Additionally, Indotherm provides comprehensive technical support and maintenance services to ensure that its customers can maximize the performance and lifespan of their induction furnaces.

The widespread adoption of induction furnace technology is a testament to its significant impact on the manufacturing industry. Manufacturers who have embraced this technology have seen improvements in production efficiency, product quality, and cost savings. Indotherm's induction furnaces have played a crucial role in enabling these advancements, making them a valuable asset for companies looking to stay competitive in today's market.

In conclusion, induction furnace technology has revolutionized the manufacturing industry, and companies like Indotherm have been at the forefront of this revolution. With their innovative and reliable induction furnaces, Indotherm has helped countless manufacturers achieve higher levels of efficiency, sustainability, and performance. As the demand for induction furnace technology continues to grow, it is clear that Indotherm will remain a key player in shaping the future of manufacturing.

Company News & Blog

Revolutionary Electric Crucible Manufacturers Transforming the Industry

Electric Crucible Manufacturers, a leading name in the industry, has revolutionized the manufacturing process of crucibles with their innovative and state-of-the-art technology. With a history spanning over several decades, this renowned company has established itself as a pioneer in the field, constantly pushing the boundaries of what is possible. Their commitment to excellence and dedication to customer satisfaction has made them a trusted partner for businesses around the globe.Founded in {}, Electric Crucible Manufacturers has always strived for perfection in their products. They have invested heavily in research and development, continuously refining their techniques and incorporating advancements in technology to stay ahead of the competition. This dedication to innovation has enabled them to create crucibles that are not only highly efficient but also durable and long-lasting.One of the key factors that set Electric Crucible Manufacturers apart from their competitors is their production process. They employ a unique technology that ensures the crucibles are manufactured with utmost precision and accuracy. This process involves a combination of automation and skilled craftsmanship, resulting in crucibles of exceptional quality.Additionally, Electric Crucible Manufacturers understands the importance of customization and adaptability in today's fast-paced market. They offer a wide range of crucibles that can be tailored to meet the specific needs of their customers. Whether it's a small-scale operation or a large industrial setup, their team of experts works closely with clients to deliver solutions that are perfectly suited to their requirements.Moreover, sustainability has always been a core value for Electric Crucible Manufacturers. They prioritize eco-friendly manufacturing practices and use materials that are both efficient and environmentally conscious. By minimizing waste and maximizing energy efficiency, they strive to reduce their carbon footprint and contribute to a greener future.Furthermore, Electric Crucible Manufacturers has established a strong customer-centric approach. They understand that each client's needs are unique, and thus, they provide personalized support and guidance throughout the entire process. From the initial consultation to after-sales service, they ensure that every customer receives the highest level of satisfaction.In an industry where precision and reliability are of paramount importance, Electric Crucible Manufacturers has set the bar high. Their commitment to delivering outstanding products and their constant drive for innovation have earned them a stellar reputation in the market. Businesses across various sectors have come to rely on their crucibles to achieve optimal performance and efficiency.Looking to the future, Electric Crucible Manufacturers envisions further advancements in their technology. They aim to continue pushing the boundaries and exploring new possibilities in the crucible manufacturing industry. With their dedicated team of professionals, they are committed to meeting the evolving needs of their customers and surpassing expectations.In conclusion, Electric Crucible Manufacturers has solidified its position as a leading manufacturer of crucibles through its relentless pursuit of excellence. With their cutting-edge technology, commitment to sustainability, and customer-centric approach, they have become a trusted partner for businesses worldwide. As they continue to innovate and adapt, Electric Crucible Manufacturers is poised to shape the future of crucible manufacturing.

Metal Melting Furnace Manufacturers in China: Key Players, Market Trends and Growth Opportunities

China Induction Metal Melting Furnace Suppliers Leverage Advanced Technology and Innovation to Boost Industry GrowthWith the rapidly growing demand for metal melting furnaces across industries worldwide, China Induction Metal Melting Furnace Suppliers have emerged as leading players in the market. These suppliers are known for their commitment to advanced technology and innovation, enabling them to provide high-quality products that meet the diverse needs of their customers.China has long been recognized as a manufacturing hub, and its induction metal melting furnace suppliers have gained significant traction in recent years. The country's robust infrastructure, skilled workforce, and focus on technological advancements have positioned it as a key player in the global market for metal melting furnaces.One prominent example of a leading China-based induction metal melting furnace supplier is {}. With years of experience in the industry, they have established a solid reputation for manufacturing reliable and efficient furnaces. However, we will avoid mentioning the specific brand name to maintain neutrality.The company employs advanced induction heating technology and sophisticated processes to ensure the highest quality products. Using electromagnetic induction, these furnaces can generate intense heat within a short period, allowing for rapid and efficient metal melting.In addition to their cutting-edge technology, {} places great emphasis on research and development. The company has a dedicated team of engineers and technicians who constantly work towards refining their furnace designs and optimizing their performance. This commitment to innovation has enabled them to stay ahead of the competition and deliver state-of-the-art products that meet the evolving needs of their customers in diverse industries.One of the key advantages of induction metal melting furnaces is their energy efficiency. These furnaces have a high heat transfer rate, reducing energy consumption and minimizing carbon emissions. This eco-friendly approach is particularly important in today's climate-conscious world.Furthermore, {} offers a wide range of customization options to cater to the specific requirements of different industries. From small-scale operations to large industrial facilities, their furnaces can be tailored to suit various capacities and operational demands. This flexibility and versatility have made their induction metal melting furnaces highly sought after in industries such as automotive, aerospace, electronics, and jewelry manufacturing.Quality control is another area where China Induction Metal Melting Furnace Suppliers have excelled. {} employs stringent quality control measures at every stage of the production process, ensuring that each furnace meets the highest standards of reliability and durability. Moreover, they are compliant with international safety regulations, providing customers with the assurance that their operations will run smoothly and efficiently.The global market for metal melting furnaces is expected to witness substantial growth in the coming years. This can be attributed to the increasing demand for metals in various sectors, ranging from automotive and construction to electronics and renewable energy. China's induction metal melting furnace suppliers are well-positioned to capitalize on this growth, thanks to their commitment to technological advancements and customer-centric approach.In conclusion, China Induction Metal Melting Furnace Suppliers, such as {}, have emerged as leaders in the market due to their dedication to advanced technology and innovation. Their ability to deliver high-quality, energy-efficient, and customizable furnaces has made them the preferred choice for industries worldwide. With the global demand for metal melting furnaces on the rise, these suppliers are poised for continued growth and success.

Get the Facts on Brass Induction Melting Furnace Manufacturers

Title: Revolutionizing Foundry Operations: The Rise of Brass Induction Melting Furnace FactoriesIntroduction: In recent years, the global foundry industry has witnessed a significant shift towards more efficient and sustainable manufacturing processes. Among the groundbreaking technological advancements, the emergence of brass induction melting furnace factories has revolutionized the way brass is produced and melted. These innovative facilities have not only propelled the manufacturing efficiency to new heights but also contributed to minimizing the environmental impact associated with traditional foundry operations. In this article, we delve deeper into the concept behind brass induction melting furnace factories and explore their numerous benefits and advantages for the industry.What are Brass Induction Melting Furnace Factories?Brass induction melting furnace factories incorporate state-of-the-art technology to improve the melting process of brass and enhance overall productivity. By utilizing induction heating, these factories can achieve precise temperature control, reduce energy consumption, and ensure consistent and high-quality brass production. The innovative design of the furnaces allows for faster melting times, improved metal purity, and increased operator safety.Company Introduction: {Company Name}, a prominent player in the foundry industry, has played a pivotal role in developing and popularizing brass induction melting furnace factories. With decades of experience and a commitment to innovation, {Company Name} has established itself as a frontrunner in providing cutting-edge solutions to foundries worldwide. Their advanced range of brass induction melting furnaces has helped foundries optimize their operations, reduce costs, and meet the growing demands of the market.Advantages of Brass Induction Melting Furnace Factories:1. Increased Efficiency: Brass induction melting furnace factories significantly improve operational efficiency. The advanced technology allows for quick melting cycles, reducing production time and enhancing output. By eliminating the need for traditional crucibles, these furnaces greatly reduce wait times for metal heating, resulting in increased productivity.2. Enhanced Energy Efficiency: Traditional foundry furnaces often suffer from excessive heat losses, leading to energy waste. Brass induction melting furnaces, on the other hand, utilize induction heating, which is highly energy-efficient. The precise heating control eliminates unnecessary energy losses and enables foundries to make substantial energy savings.3. Improved Metal Quality: The induction heating process in brass melting furnaces ensures consistent and uniform heating, resulting in higher metal quality. The absence of impurities and better temperature control leads to improved mechanical properties and enhanced product performance. Subsequently, this quality boost increases the competitiveness of the products manufactured using brass induction melting furnace factories.4. Sustainable Manufacturing: With a growing emphasis on sustainability, brass induction melting furnace factories are an eco-friendly alternative to traditional foundry operations. By reducing energy consumption and waste, these factories contribute to minimizing the environmental impact associated with brass production. The adoption of cleaner and more efficient melting processes aligns with global efforts to promote green manufacturing and eco-conscious practices.5. Operator Safety: Brass induction melting furnaces prioritize operator safety by minimizing direct contact with the molten metal. The advanced technology allows for remote control and monitoring, reducing the risk of accidents or injuries. Furthermore, the enclosed design of the furnaces prevents metal splatter and enhances overall safety measures in the workplace.Conclusion:As the foundry industry continues to evolve, brass induction melting furnace factories represent the future of efficient and sustainable brass production. With advancements in technology and a strong commitment to innovation, {Company Name} and other industry leaders are driving the adoption of these cutting-edge facilities. By streamlining operations, improving energy efficiency, and prioritizing sustainability, brass induction melting furnace factories offer immense value to foundries worldwide. Embracing these advancements will undoubtedly pave the path for a more efficient and environmentally conscious manufacturing sector.

Innovative Induction Copper Melting Furnaces Now Available for Industrial Applications in China

China Induction Copper Melting Furnace Factory, one of the leading manufacturers in the industry, is keenly focused on revolutionizing the copper melting process. With their exceptional expertise and state-of-the-art technology, the company aims to redefine efficiency, precision, and eco-friendliness in the melting furnace industry. Their commitment to innovation and customer satisfaction has earned them a prominent position in the market.The China Induction Copper Melting Furnace Factory sets itself apart from competitors with its cutting-edge induction heating technology. This technology allows for a highly efficient and precise melting process, reducing energy consumption and ensuring minimal heat loss during production. By utilizing electromagnetic induction to generate heat directly within the material being melted, these furnaces offer unparalleled temperature control and uniformity.In addition to its advanced technology, the factory also places great emphasis on environmental sustainability. The China Induction Copper Melting Furnace Factory is fully aware of the impact of industrial processes on the environment, and has implemented various measures to reduce its carbon footprint. For instance, they have developed energy-saving systems that effectively minimize power consumption, resulting in reduced greenhouse gas emissions. This commitment to eco-friendliness not only benefits the environment but also helps businesses lower their operational costs.Furthermore, the China Induction Copper Melting Furnace Factory is deeply committed to providing top-notch customer service and support. With a team of highly skilled engineers and technicians, they offer comprehensive assistance from installation to maintenance. The company understands the importance of a reliable and efficient melting furnace in the production process. Therefore, they make it a priority to ensure that their clients receive the best possible service and prompt technical support whenever required.The factory's dedication to quality is evident in its rigorous testing and quality control procedures. Each furnace undergoes thorough inspection and testing before delivery, ensuring that it meets the highest industry standards. This attention to detail guarantees that customers receive a durable and high-performance product that will withstand the demands of continuous use.China Induction Copper Melting Furnace Factory's clientele spans across various industries, including metal processing, foundries, and recycling facilities. Their furnaces are widely used for melting copper and its alloys, providing an essential tool for these industries’ operations. The factory's ability to cater to various business requirements has contributed to its growing reputation as a reputable and reliable melting furnace manufacturer.Looking ahead, the China Induction Copper Melting Furnace Factory plans to continue its commitment to innovation and technological advancement. By staying at the forefront of industry trends and continuously updating their product offerings, they aim to provide customers with cutting-edge solutions for their copper melting needs. Through ongoing research and development, the company strives to enhance their furnaces' efficiency, performance, and sustainability, solidifying their position as an industry leader.In conclusion, the China Induction Copper Melting Furnace Factory is a standout player in the melting furnace industry. With its advanced technology, commitment to eco-friendliness, and dedication to customer satisfaction, the factory has earned its reputation as a reliable and innovative manufacturer. As they continue to evolve and improve their product offerings, they are poised to remain at the forefront of the industry, shaping and revolutionizing the copper melting process.

Top Zinc Melting Furnace Factories: Discover the Best Manufacturers in the Industry

Title: Advancements in Zinc Melting Furnace Technology Revolutionize the IndustryIntroduction:Zinc melting furnace factories play a crucial role in the manufacturing process of various industries, including automotive, construction, and electronics. These factories are responsible for melting and refining zinc to its molten form, which is then used for various applications. With technological advancements, several manufacturers have made significant strides in improving these furnaces' efficiency, safety, and environmental impact. In this article, we explore the recent developments in zinc melting furnace technology and their impact on the industry.1. Enhanced Efficiency through Innovative Designs:Leading zinc melting furnace manufacturers have been focusing on improving efficiency to meet the growing demands of zinc-consuming industries. They have developed advanced designs that optimize heat transfer, resulting in faster and more efficient melting processes. These innovative designs utilize various methods such as induction heating, electric resistive heating, or fossil fuel combustion to achieve optimal melting conditions.Furthermore, precise temperature control mechanisms and advanced insulation materials have been integrated into these furnaces, minimizing heat loss and enabling uniform melting throughout the entire process. As a result, manufacturers can achieve higher throughput capacities while reducing energy consumption, ultimately leading to cost savings and increased productivity.2. Emphasis on Safety Measures:Ensuring worker safety is of utmost importance in zinc melting furnace factories. Recent advancements have brought forth enhanced safety features, making the operating environment safer for workers. Furnaces now come equipped with sensor-based systems that continuously monitor various parameters like temperature, pressure, and gas leakage. In the event of any abnormalities or hazardous situations, these systems can automatically shut down the furnace or trigger alarms, thereby preventing accidents and ensuring a secure work environment.Moreover, improved ventilation and exhaust systems have been implemented to minimize the health risks associated with exposure to metal fumes and other harmful byproducts generated during the melting process. These advancements have significantly reduced the health hazards for workers, leading to improved overall well-being and better work conditions.3. Environmental Sustainability:Zinc melting furnace factories have made notable progress in reducing their environmental footprint. Manufacturers have adopted cleaner and more sustainable energy sources, such as electricity from renewable sources or use of cleaner fuels like natural gas, minimizing greenhouse gas emissions. Additionally, advanced filtration systems have been introduced to capture and treat harmful byproducts like particulate matter, sulfur dioxide, and nitrogen oxides generated during the melting process.Furthermore, recycling initiatives have gained momentum, allowing for the recycling and reuse of zinc scrap and dross generated during the manufacturing process. This significantly reduces waste disposal, conserves natural resources, and promotes a circular economy approach.Conclusion:Recent advancements in zinc melting furnace technology have revolutionized the industry, bringing forth numerous benefits such as enhanced efficiency, improved safety measures, and a reduced environmental impact. The integration of innovative designs, refined temperature control mechanisms, and advanced safety features have enabled manufacturers to achieve higher productivity while safeguarding the well-being of workers. Moreover, the adoption of sustainable practices, including the use of cleaner energy sources and recycling initiatives, have promoted environmental sustainability within the industry.As the demand for zinc in various industries continues to grow, it is encouraging to witness the continuous efforts made by zinc melting furnace factories to push the boundaries of technological innovation. These advancements not only contribute to the industry's growth but also address the pressing concerns of efficiency, safety, and sustainability.

Efficient Zinc Melting Furnace Designs for High-Quality Production

Zinc Melting Furnace: Transforming the Metal Industry for a Sustainable FutureThe metal industry has always been one of the key components of the world economy. From infrastructure development to manufacturing, metal is an essential material in various applications. However, the process of producing metals is energy-intensive, resulting in high greenhouse gas emissions and ecological impact. One of the most significant contributors to this industry is the zinc smelting process, and thus, finding sustainable solutions has become a priority for many companies.This is where the Zinc Melting Furnace, developed by a renowned metal smelting equipment manufacturer (brand name removed), comes into the picture. The furnace is designed to eliminate the environmental impact caused by traditional zinc smelting and provide an energy-efficient and cost-effective solution to its users.The furnace, designed with advanced technology, is capable of melting zinc and related alloys in a highly controlled and efficient manner using electric heating elements. One of the biggest advantages of this process is that it eliminates the need for fossil fuels, commonly used in traditional smelting, leading to the reduction of greenhouse gas emissions.Furthermore, the Zinc Melting Furnace is equipped with advanced features that enable the recycling of zinc and other valuable materials that would otherwise be lost during the traditional smelting process. This reduction in waste not only benefits the environment but also provides a significant cost advantage to the user.One of the significant advantages of this furnace is its flexibility. It can be used in various applications, including galvanizing, die-casting, and the production of brass and bronze. In addition, it can also be used in recycling facilities to recover zinc from scrap material.According to the company, the Zinc Melting Furnace has been tested and proven successful in various industrial applications. It has helped companies reduce their carbon footprint, adhere to environmental regulations, and provide an energy-efficient and cost-effective smelting solution.The company’s commitment to sustainability doesn’t end with just the production of the Zinc Melting Furnace. It has a comprehensive program for designing and manufacturing equipment that is environmentally conscious. The company aims to reduce its carbon footprint significantly by promoting energy-efficient manufacturing processes, using renewable energy, and reducing waste.Furthermore, the company has a strong emphasis on providing its customers with a holistic solution to their sustainability-related needs. It offers consultation on regulatory requirements, energy efficiency, and eco-friendly production methods to ensure that its customers achieve their sustainability goals.As the world unites to address climate change, the Zinc Melting Furnace is a testament to the potential for technology to transform industries and provide sustainable solutions. The company’s focus on sustainability, combined with its advanced technology, positions it as a leader in the metal smelting equipment market. It is an example of how innovation can drive environmental stewardship and provide economic benefits simultaneously.In conclusion, the Zinc Melting Furnace is a game-changer in the metal industry, offering a sustainable and energy-efficient solution to traditional smelting processes. With its advanced technology and flexible applications, it provides a holistic and cost-effective solution to companies looking to achieve their sustainability goals. The company’s commitment to eco-friendly manufacturing and its dedication to providing a comprehensive sustainability solution position it as a leader in the metal smelting equipment market.

Top-rated Industrial Melting Furnace for Efficient Metal Processing

Industrial melting furnaces have become a crucial component of various manufacturing processes. These furnaces are designed to heat metals and other materials to their melting points, enabling them to be molded into various shapes and forms. As such, they are commonly used in industries such as metal casting, foundries, and jewelry making.With increasing demand for reliable and efficient industrial melting furnaces, various manufacturers have emerged in the market. However, one company stands out for its commitment to producing high-quality melting furnaces that meet the needs of diverse industries. This company has gained recognition for its innovative designs, durability, and reliability, making it a leading provider of industrial melting furnaces globally.The industrial melting furnaces produced by this company have a variety of applications across different industrial sectors. They are designed to melt various metals, from aluminum to steel, and enable them to be shaped into different forms for use in different industrial processes. These furnaces come in different sizes and specifications to meet the specific needs of customers, ranging from small-scale foundries to large industrial giants.Moreover, this company designs furnaces that are energy-efficient, environmentally friendly, and safe to use. These features have made it a go-to provider for organizations looking to reduce their energy consumption and cut operational costs. Additionally, the furnaces come with features that improve their functionality and safety, such as electronic controls, specialized cooling systems, and interlocks that prevent accidents in the workplace.The durability of the industrial melting furnaces produced by this company is another factor that sets it apart from its competitors. The furnaces are made of high-quality materials that can withstand high temperatures and resist corrosion over extended periods. This feature allows the furnaces to last long, even in harsh industrial environments with extreme temperatures and chemical exposure.In line with its mission to offer excellent customer service, this company provides comprehensive support and maintenance services to customers worldwide. The company has a team of expert technicians who offer round-the-clock customer support and maintenance services, ensuring that its customers can keep their furnaces working efficiently and effectively. Additionally, the company offers various financing options and payment plans to customers, making it easier for them to afford industrial melting furnaces that meet their needs.ConclusionIndustrial melting furnaces play a critical role in the production process of various industries. As such, it is essential to invest in high-quality furnaces that can provide reliability, durability, and efficiency. This company has carved out a niche in the industry, providing state-of-the-art furnaces that meet the diverse needs of customers in various sectors. Its commitment to innovation, energy efficiency, and safety has earned it a reputation as a leading provider of industrial melting furnaces worldwide. With excellent customer service and maintenance services, this company is poised to provide the best industrial melting furnaces and reliable support to customers today and in the future.

Top Suppliers of Aluminium Melting Rotary Furnaces in the Market

Best Aluminium Melting Rotary Furnace Suppliers Combine Quality with Promising Company IntroductionAluminium melting rotary furnaces play a pivotal role in the aluminum production industry, ensuring efficient and reliable melting of aluminum scrap. As the demand for aluminum continues to rise, the need for high-quality melting equipment becomes essential. In this regard, it is crucial to identify the best suppliers who combine exceptional product quality with a promising company introduction. This article explores the leading aluminium melting rotary furnace suppliers who are setting the benchmark for excellence in the industry.One prominent supplier is a company that has been providing top-notch melting furnace solutions for over two decades. Their commitment to innovation, quality, and customer satisfaction sets them apart from their competitors. With a team of experienced engineers and technicians, they design and manufacture cutting-edge aluminium melting rotary furnaces that meet the highest industry standards.This supplier takes pride in its research and development capabilities, ensuring that they employ the latest technology and methodology to create furnaces that optimize energy efficiency and reduce emissions. Their furnaces are designed to achieve maximum heat transfer, resulting in faster and more efficient melting processes. Additionally, their commitment to environmental responsibility is evident through their furnaces' low energy consumption and low emissions.Furthermore, this supplier understands the importance of customization to meet specific customer requirements. They offer a wide range of furnace capacities, from small-scale operations to large-scale industrial melting processes. Their team works closely with clients to tailor their furnaces according to individual needs, ensuring optimal performance and efficiency.Another notable supplier in the industry boasts a rich company introduction, highlighting their expertise and longstanding reputation. With a heritage spanning several decades, this supplier has become a trusted name in the aluminium melting furnace market. They are known for their commitment to quality, reliability, and exceptional customer service.This supplier's furnaces are designed with advanced features to ensure seamless and efficient melting operations. Their rotary furnaces utilize high-quality materials and components, ensuring durability and longevity. Moreover, their furnaces are equipped with advanced control systems that allow for precise temperature and process management. This ensures consistent melting results, reducing downtime and improving overall productivity.In line with their commitment to customer satisfaction, this supplier provides comprehensive technical support and after-sales services. They offer installation and commissioning of their furnaces, along with training programs for operators to ensure optimal furnace utilization. Additionally, they have a team of experienced technicians who provide timely maintenance and repair services, minimizing downtime and maximizing furnace lifespan.When it comes to the best aluminium melting rotary furnace suppliers, these companies stand out due to their commitment to quality, innovation, and customer satisfaction. Their exceptional products, combined with their promising company introductions, make them the go-to choices for businesses in the aluminum industry.It is important for aluminum producers to partner with reliable suppliers who can provide them with top-notch melting equipment that meets their specific needs. The above-mentioned suppliers offer a wide range of furnaces, ensuring that they can cater to both small-scale and large-scale operations. Their technical expertise, attention to detail, and commitment to environmental responsibility set them apart in the industry.As the demand for aluminum continues to grow, it is imperative for companies to invest in high-quality melting equipment that can meet production requirements efficiently and sustainably. With their innovative furnaces and customer-centric approaches, these suppliers are poised to play a significant role in shaping the future of the aluminum industry.

Quality Vacuum Induction Suppliers for industrial needs

Vacuum Induction Suppliers, a leading provider of vacuum induction melting and casting systems, has recently announced the launch of their newest product line. With a focus on innovation and cutting-edge technology, the company aims to deliver high-quality solutions for the metal casting industry.The company has been at the forefront of the industry for over 30 years, and their expertise in vacuum induction melting and casting has made them a preferred supplier for many global manufacturers. With a strong commitment to research and development, Vacuum Induction Suppliers has continuously pushed the boundaries of what is possible in metal casting technology.The new product line is the result of years of research and development, and it promises to deliver even greater performance and efficiency for their customers. With a focus on precision and reliability, the new systems are designed to meet the demands of the modern metal casting industry.One of the key features of the new product line is its advanced control system, which allows for precise monitoring and adjustment of the melting and casting process. This level of control not only ensures consistent quality in the final product, but also contributes to improved energy efficiency and reduced waste.In addition to the advanced control system, the new product line also includes enhancements to the overall design and construction of the systems. These improvements are aimed at increasing durability and reducing maintenance requirements, ultimately leading to lower operating costs and increased uptime for their customers.The launch of the new product line is a reflection of Vacuum Induction Suppliers' commitment to continuous improvement and innovation. By staying ahead of the curve with their technology, the company is positioning itself as a reliable and forward-thinking partner for the metal casting industry.In a statement, the company's CEO expressed their excitement about the new product line, stating, "We are proud to introduce our latest advancements in vacuum induction melting and casting technology. Our team has worked tirelessly to bring these new systems to market, and we are confident that they will set a new standard for performance and quality in the industry."The company's dedication to delivering high-quality solutions has earned them a strong reputation in the industry, and their customer base continues to grow as a result. With a focus on providing exceptional service and support, Vacuum Induction Suppliers has built long-lasting relationships with their customers, who rely on them for their expertise and reliability.As the metal casting industry continues to evolve, Vacuum Induction Suppliers remains committed to staying at the forefront of technological advancements. By investing in research and development, the company is well-positioned to meet the changing needs of their customers and to provide innovative solutions that drive the industry forward.With the launch of their new product line, Vacuum Induction Suppliers is sending a clear message to the industry: they are dedicated to pushing the boundaries of what is possible in metal casting technology, and they will continue to deliver cutting-edge solutions for their customers. As the company looks to the future, it remains focused on maintaining its position as a leader in the industry and providing unparalleled value to its customers.

Steel Melting with Induction Furnace for Efficient Processes

Title: Revolutionary Induction Furnace Enhances Steel Melting ProcessIntroduction:With an unwavering commitment to innovation and excellence, a leading industrial equipment manufacturer presents a groundbreaking induction furnace designed specifically for steel melting. This cutting-edge furnace revolutionizes the steel industry with its advanced technology, optimized efficiency, and sustainability. Developed by the company's team of experts, this induction furnace promises to redefine steel melting processes, ensuring superior quality and productivity for manufacturers worldwide.Enhanced Steel Melting Process:The newly introduced induction furnace combines state-of-the-art technology with an array of features to optimize the steel melting process. By utilizing electromagnetic induction, this advanced furnace quickly and efficiently transforms raw materials into molten steel, eliminating the traditional reliance on fuel combustion.The furnace's electromagnetic field induces electric currents within the steel, resulting in rapid and uniform heating. This induction technology guarantees precise temperature control and homogeneous mixing, thus obviating the need for manual stirring or mixing agents. The elimination of these labor-intensive processes not only saves time and effort but also reduces overall production costs.Furthermore, the furnace's innovative design ensures minimal heat loss, increasing energy efficiency. The advanced insulation materials and optimized refractory lining retain heat effectively, minimizing energy consumption without compromising performance. This sustainable feature aligns with global efforts towards reducing carbon footprints, making it an eco-friendly choice for steel manufacturers.Unparalleled Performance and Customization:Equipped with cutting-edge control systems, the induction furnace offers unparalleled performance and flexibility. Manufacturers can easily adjust its parameters, such as power input and temperature, ensuring precise melting according to different steel grades and specific production requirements. The furnace's adaptable nature enables manufacturers to achieve consistent quality while accommodating changing market demands.Moreover, the furnace's user-friendly interface provides real-time monitoring and data analysis, optimizing operational efficiency. The integrated sensors and feedback mechanisms enable quick adjustments, minimizing downtime due to equipment failure and ensuring continuous production. This feature contributes to increased output, reduced production costs, and improved overall profit margins for steel manufacturers.Installation and Technical Support:In addition to providing a groundbreaking induction furnace, the company offers comprehensive installation assistance and technical support. Their team of experienced technicians ensures a smooth transition during the installation process, minimizing operational disruptions. Furthermore, the company provides professional training to operators, familiarizing them with the furnace's advanced features, safety protocols, and maintenance practices.Additionally, the company's dedicated technical support team is available 24/7 to address any queries or resolve technical issues promptly. This commitment to customer service ensures uninterrupted operations and maximizes the longevity of the induction furnace, preventing potential downtime and associated financial losses.Conclusion:With its revolutionary technology, optimized efficiency, and commitment to sustainability, the newly developed induction furnace presents a game-changing solution for the steel industry. By integrating advanced electromagnetic induction, precise temperature control, and superior energy efficiency, this furnace guarantees enhanced performance, reduced costs, and increased profitability for manufacturers worldwide.With comprehensive installation and technical support, the company aims to empower steel manufacturers, equipping them with cutting-edge technology and expertise. As the steel industry continues to evolve, this induction furnace sets a benchmark for innovation and paves the way for a more efficient, sustainable, and profitable future.