High-Quality Digital Melting Furnace Factory in China: Industry News

By:Admin

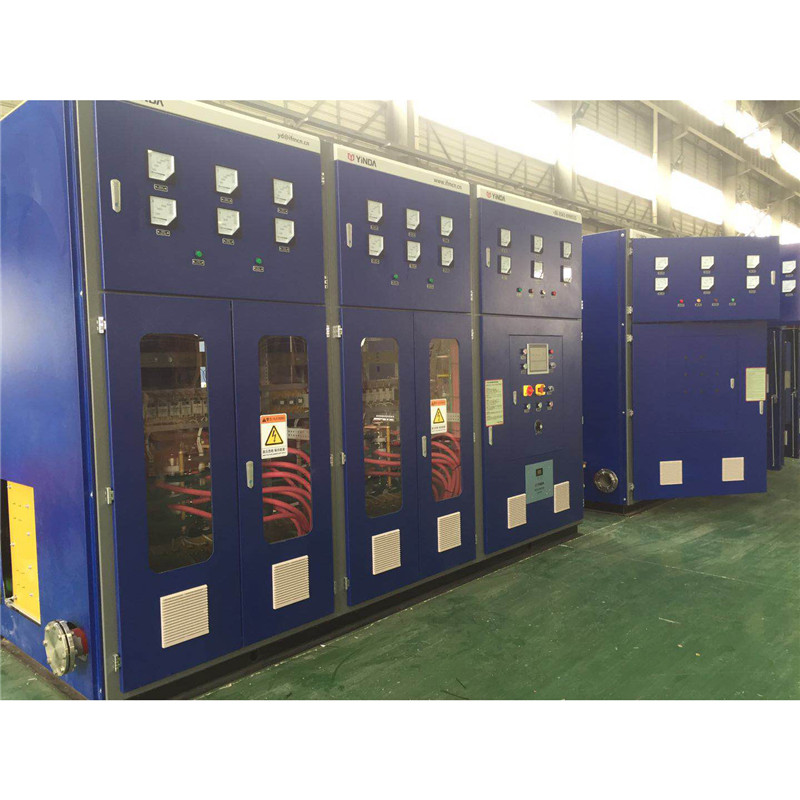

Specializing in the design, development, and production of digital melting furnaces, the factory has quickly become a leading player in the market. With a focus on meeting the evolving needs of the industry, the factory utilizes advanced technology and high-quality materials to manufacture its products.

The factory's melting furnaces are designed to meet the diverse needs of clients across various industries, from metal casting to jewelry production. With a strong emphasis on precision and efficiency, the furnaces are equipped with digital controls that ensure accurate and consistent melting processes. This level of precision not only improves the quality of the final product but also enhances energy efficiency and reduces production costs.

In addition to its cutting-edge technology, the factory's commitment to quality is evident in its rigorous testing and quality control processes. Each furnace undergoes thorough testing to ensure reliability and performance, providing customers with peace of mind and confidence in their investment.

Furthermore, the factory's team of skilled engineers and technicians are dedicated to providing exceptional service and support to clients. From initial consultation to installation and maintenance, the factory's experts are committed to assisting customers every step of the way, ensuring that they get the most out of their melting furnace.

The factory's success can be attributed not only to its superior technology and quality but also its ability to adapt to the ever-changing demands of the industry. By continuously investing in research and development, the factory remains at the forefront of innovation, introducing new features and capabilities that meet the needs of modern manufacturing processes.

Moreover, the factory's commitment to sustainability is evident in its efforts to minimize environmental impact. Its melting furnaces are designed to optimize energy consumption, reducing waste and carbon emissions. This focus on sustainability aligns with the growing industry trend towards eco-friendly and efficient manufacturing practices.

As the demand for advanced melting furnaces continues to grow, the factory remains well-positioned to meet the needs of the market. With an unwavering commitment to excellence, innovation, and sustainability, the factory is set to solidify its position as a leading manufacturer in the industry.

In conclusion, China Digital Melting Furnace Factory has quickly risen to prominence as a top manufacturer of cutting-edge melting furnaces. With its focus on technology, quality, and sustainability, the factory is well-equipped to meet the evolving needs of the manufacturing industry. As it continues to innovate and expand its product offerings, the factory is poised to remain a key player in the market for years to come.

Company News & Blog

Top Automatic Melting Furnace Manufacturer offers the Latest Technology in Furnace Designs

Automatic Melting Furnace Manufacturer Company, a leading provider of advanced melting furnace solutions, has recently announced the launch of their latest innovative product, the AMF-5000. This state-of-the-art melting furnace is designed to revolutionize the melting process, providing unparalleled efficiency and precision for a wide range of industrial applications.With over 20 years of experience in the industry, Automatic Melting Furnace Manufacturer Company has established itself as a trusted name in the field of melting furnace technology. The company is dedicated to delivering high-quality, reliable products that meet the evolving needs of their customers, and the AMF-5000 is a testament to their commitment to innovation and excellence.The AMF-5000 is equipped with advanced features that set it apart from traditional melting furnaces. One of the key highlights of this new product is its automatic control system, which allows for precise temperature regulation and consistent heating performance. This cutting-edge technology ensures that the melting process is carried out with maximum efficiency, leading to reduced energy consumption and shorter processing times.In addition, the AMF-5000 is designed to accommodate a wide range of materials, making it suitable for use in diverse industrial settings. Whether it's melting aluminum, copper, or other metals, this versatile furnace can handle the task with ease, delivering superior results every time. Its robust construction and durable components make it a reliable and long-lasting solution for industrial melting needs.Furthermore, Automatic Melting Furnace Manufacturer Company has integrated advanced safety features into the AMF-5000 to ensure the wellbeing of operators and personnel. The furnace is equipped with comprehensive safety systems that monitor and control various parameters, mitigating the risk of accidents and ensuring a secure working environment.The launch of the AMF-5000 marks a significant milestone for Automatic Melting Furnace Manufacturer Company, demonstrating their ability to stay at the forefront of technological advancements in the melting furnace industry. The company's commitment to research and development has resulted in a product that is set to redefine the standards for melting furnace performance and efficiency."We are thrilled to introduce the AMF-5000 to the market," said the spokesperson for Automatic Melting Furnace Manufacturer Company. "This cutting-edge furnace represents a significant leap forward in melting technology, and we are confident that it will deliver exceptional value to our customers. We have worked tirelessly to develop a product that combines advanced functionality with user-friendly operation, and we believe that the AMF-5000 will set a new benchmark for melting furnace performance."In addition to the launch of the AMF-5000, Automatic Melting Furnace Manufacturer Company continues to offer comprehensive support and maintenance services to ensure that their customers can maximize the performance and longevity of their melting furnaces. The company's team of highly skilled technicians is readily available to provide assistance and expertise, reaffirming their commitment to delivering a superior customer experience.Moving forward, Automatic Melting Furnace Manufacturer Company remains focused on driving innovation in the melting furnace industry, with plans to further expand their product range and continue pushing the boundaries of technological advancement. Through their dedication to excellence and customer-centric approach, the company is well-positioned to maintain its leadership in the market and solidify its reputation as a trusted partner for industrial melting solutions.

Top Manufacturers of Smelting Equipment for Your Business Needs

The smelting industry plays a crucial role in the manufacturing sector by converting raw materials such as metal ores into pure metals. To achieve this, smelting equipment is required to extract and refine these metals efficiently and effectively. Choosing the best smelting equipment manufacturer is essential for the success of any smelting operation.With this in mind, it is imperative to highlight the significance of selecting a reliable and reputable smelting equipment manufacturer such as {}. They have firmly established themselves as one of the leading and most trusted suppliers of smelting equipment in the industry. Their commitment to delivering advanced, high-quality smelting equipment has earned them a reputation for excellence and innovation.Established in [], {} has continuously strived to provide the best-in-class smelting equipment to a wide range of industries including mining, metallurgy, and metal recycling. They have amassed a wealth of experience and expertise in designing and manufacturing smelting equipment that meets the stringent requirements of their diverse clientele.{}’s product range includes a variety of smelting equipment such as furnaces, crucibles, and specialized machinery for different smelting processes. These products are designed to ensure optimal efficiency, cost-effectiveness, and environmental sustainability, making them the preferred choice for numerous smelting operations worldwide.In addition to supplying standard smelting equipment, {} also offers custom solutions tailored to the specific requirements of their clients. Their team of highly skilled engineers and technicians collaborates closely with customers to design and manufacture bespoke smelting equipment that aligns with their unique manufacturing needs.One of {}’s key strengths is their relentless commitment to research and development. They continuously invest in upgrading their manufacturing processes and improving the performance and capabilities of their smelting equipment. By staying at the forefront of technological advancements, they can offer cutting-edge solutions that enable their clients to stay competitive in their respective industries.Moreover, {} places a strong emphasis on quality control and assurance. All their smelting equipment undergoes rigorous testing and inspection to ensure that they meet the highest standards of safety, reliability, and performance. This uncompromising dedication to quality has positioned {} as a trusted partner for companies seeking premium smelting equipment.Furthermore, {} also provides comprehensive after-sales support and maintenance services to their clients. They understand the importance of keeping smelting operations running smoothly and are committed to offering timely assistance and technical expertise whenever needed. This level of customer service has solidified their long-term relationships with many satisfied customers.By choosing {} as their preferred smelting equipment manufacturer, companies can benefit from the peace of mind that comes with partnering with an industry leader. With a proven track record of delivering top-notch products and exceptional customer service, {} continues to set the benchmark for smelting equipment manufacturing.In conclusion, selecting the best smelting equipment manufacturer is paramount for the success of any smelting operation. With its unwavering dedication to quality, innovation, and customer satisfaction, {} has undoubtedly earned its place as the top choice for companies seeking reliable and advanced smelting equipment solutions. With a strong focus on research and development, quality control, and customer support, {} is well-positioned to continue leading the way in the smelting equipment manufacturing industry.

Top 5 Industrial Aluminum Melting Furnace Suppliers for Your Business Needs

The demand for industrial aluminum melting furnaces is on the rise as the manufacturing sector continues to grow. As a result, the need for reliable and reputable suppliers of these furnaces has never been greater. When it comes to sourcing the best industrial aluminum melting furnace suppliers, one company stands out among the rest. With its commitment to quality, innovation, and customer satisfaction, {} has become a leading supplier in the industry.Founded in {}, {} has quickly established itself as a trusted name in the industrial furnace manufacturing industry. The company specializes in the design, manufacture, and supply of a wide range of industrial aluminum melting furnaces, catering to the diverse needs of its global clientele. With a focus on delivering high-quality products and exceptional service, {} has earned a reputation for excellence and reliability.One of the key factors that set {} apart from other suppliers is its unwavering commitment to innovation and technological advancement. The company invests heavily in research and development to stay ahead of the curve and continuously improve its product offerings. This dedication to innovation has led to the development of cutting-edge aluminum melting furnace technologies that are highly efficient, cost-effective, and environmentally friendly. As a result, {}'s furnaces are widely regarded as some of the best in the industry, providing customers with the performance and reliability they demand.In addition to its focus on innovation, {} places a strong emphasis on quality in every aspect of its business. From the materials used in its furnaces to the manufacturing processes and quality control measures, the company upholds the highest standards to ensure that its products meet and exceed customer expectations. By prioritizing quality, {} has built a loyal customer base that relies on its furnaces for their critical industrial melting operations.Furthermore, {} takes great pride in its customer-centric approach to business. The company works closely with its clients to understand their specific requirements and provide tailored solutions that meet their unique needs. Whether it's a standard aluminum melting furnace or a custom-designed solution, {} has the expertise and flexibility to deliver the right product for any application. With a focus on building long-term partnerships, the company places a strong emphasis on customer satisfaction, ensuring that its clients receive the support and service they need to succeed.As a result of these core values and business practices, {} has emerged as a leading supplier of industrial aluminum melting furnaces. The company's dedication to quality, innovation, and customer satisfaction has set it apart from its competitors and earned it the trust of industry professionals worldwide. With a strong track record of success and a commitment to continuous improvement, {} is well-positioned to meet the growing demand for high-quality aluminum melting furnaces in the years to come.In conclusion, as the demand for industrial aluminum melting furnaces continues to rise, choosing the right supplier is essential for businesses looking to maximize their production efficiency and quality. With its focus on innovation, quality, and customer satisfaction, {} stands out as a top choice for companies in need of reliable and high-performance aluminum melting furnaces. By partnering with {} as their supplier, businesses can benefit from the company's expertise, advanced technologies, and unwavering commitment to excellence in industrial furnace manufacturing.

High-Quality Titanium Melting Furnace Factory: Find Your Ideal Solution Today!

Titanium Melting Furnace Factory is a leading manufacturer of high-quality titanium melting furnaces. With a strong focus on innovation and quality, the company has established itself as a leader in the industry. From its state-of-the-art manufacturing facility to its dedicated team of experts, Titanium Melting Furnace Factory is committed to providing customers with the most reliable and efficient melting furnaces on the market.The company's commitment to excellence is evident in every aspect of its operations. The manufacturing process begins with the selection of the highest quality materials, ensuring that each furnace is built to last. Expert engineers and technicians then utilize cutting-edge technology to design and construct the furnaces to exacting standards. Rigorous testing and quality control measures are also implemented to guarantee that every furnace meets the company's stringent requirements.In addition to its dedication to quality, Titanium Melting Furnace Factory is also focused on innovation. The company continuously invests in research and development to stay at the forefront of industry advancements. This commitment to innovation has led to the development of groundbreaking technologies that improve the performance and efficiency of its furnaces. As a result, customers can rely on Titanium Melting Furnace Factory to deliver the most advanced and reliable melting furnaces available.One of the key factors that set Titanium Melting Furnace Factory apart from its competitors is its customer-oriented approach. The company understands that every customer has unique requirements, and it is committed to providing customized solutions to meet those needs. Whether it's a standard furnace model or a specialized design, Titanium Melting Furnace Factory works closely with customers to ensure that they receive the perfect melting furnace for their specific applications.Furthermore, the company's dedication to customer satisfaction extends beyond the initial sale. Titanium Melting Furnace Factory offers comprehensive support and maintenance services to ensure that its furnaces continue to operate at peak performance. From installation and training to ongoing technical assistance, customers can rely on the company's team of experts to provide the support they need, when they need it.As a responsible corporate citizen, Titanium Melting Furnace Factory also places a high priority on sustainability and environmental stewardship. The company's manufacturing processes are designed to minimize waste and energy consumption, while its products are engineered to maximize efficiency and reduce environmental impact. By choosing Titanium Melting Furnace Factory, customers can be confident that they are not only getting the best melting furnaces, but also supporting a company that is committed to sustainability.In conclusion, Titanium Melting Furnace Factory is a leading manufacturer of high-quality melting furnaces, renowned for its commitment to excellence, innovation, and customer satisfaction. From its cutting-edge manufacturing processes to its dedication to sustainability, the company goes above and beyond to deliver the most reliable and efficient furnaces on the market. For businesses looking for top-of-the-line titanium melting furnaces, Titanium Melting Furnace Factory is the clear choice.

Efficient Induction Furnace for Industrial Heating Processes

Induction Furnace Technology Revolutionizing the Manufacturing IndustryIn the fast-paced world of manufacturing, the need for efficient and reliable equipment is of utmost importance. Companies are constantly seeking new technologies and innovations to increase productivity and reduce costs. One such technology that has been revolutionizing the manufacturing industry is induction furnace technology.Induction furnaces utilize the principle of induction heating to melt metals. This technology has become increasingly popular in the manufacturing sector due to its numerous advantages over traditional methods of metal melting. The efficiency and precision of induction furnaces make them an essential tool for companies involved in metal melting and casting.One company that has been leading the way in the development and production of induction furnaces is Indotherm. Since its inception, Indotherm has been at the forefront of innovation in the field of induction heating technology. The company has a rich history of providing cutting-edge solutions to the manufacturing industry, and its induction furnaces are no exception.Indotherm's induction furnaces are designed to provide unmatched performance and reliability. They are capable of melting a wide range of metals, including steel, iron, copper, and aluminum, making them suitable for a variety of manufacturing applications. The company's commitment to quality and innovation has made its induction furnaces highly sought after by manufacturers around the world.Indotherm's induction furnaces are known for their energy efficiency and environmental sustainability. Unlike traditional methods of metal melting, induction furnaces do not rely on fossil fuels for heating. Instead, they use electromagnetic induction to generate heat, resulting in significantly lower energy consumption and carbon emissions. This makes them an attractive option for companies looking to reduce their environmental footprint while improving their bottom line.Furthermore, Indotherm's induction furnaces offer unparalleled precision and control. The advanced technology incorporated into these furnaces allows for precise temperature control and uniform heating, resulting in high-quality metal melts. This level of precision is essential for manufacturing processes that require exacting standards, such as the production of automotive parts, aerospace components, and industrial machinery.Indotherm's induction furnaces are also designed with ease of use and maintenance in mind. The company's commitment to customer satisfaction is evident in the user-friendly interfaces and robust construction of its furnaces. Additionally, Indotherm provides comprehensive technical support and maintenance services to ensure that its customers can maximize the performance and lifespan of their induction furnaces.The widespread adoption of induction furnace technology is a testament to its significant impact on the manufacturing industry. Manufacturers who have embraced this technology have seen improvements in production efficiency, product quality, and cost savings. Indotherm's induction furnaces have played a crucial role in enabling these advancements, making them a valuable asset for companies looking to stay competitive in today's market.In conclusion, induction furnace technology has revolutionized the manufacturing industry, and companies like Indotherm have been at the forefront of this revolution. With their innovative and reliable induction furnaces, Indotherm has helped countless manufacturers achieve higher levels of efficiency, sustainability, and performance. As the demand for induction furnace technology continues to grow, it is clear that Indotherm will remain a key player in shaping the future of manufacturing.

Top Furnace Factory: Innovation in Melting Technology

Best Superbmelt Furnace Factory, a leading manufacturer of industrial furnaces, has established itself as a reliable and innovative company in the field of metal melting and heat treatment. With cutting-edge technology and a commitment to quality, the company has earned a strong reputation for delivering high-performance furnaces to a diverse range of industries.Founded in [year], Best Superbmelt Furnace Factory has continually sought to push the boundaries of furnace technology, providing solutions that meet the evolving needs of its customers. The company's dedication to research and development has resulted in a range of advanced furnace systems that offer energy efficiency, precision control, and superior reliability.One of the key factors behind the success of Best Superbmelt Furnace Factory is its unwavering focus on customer satisfaction. By understanding the unique requirements of each client, the company is able to tailor its furnace solutions to deliver the best possible results. This personalized approach has led to longstanding partnerships with a wide array of customers, from small businesses to multinational corporations.Best Superbmelt Furnace Factory's commitment to quality is evident in every aspect of its operations. From the careful selection of materials to the rigorous testing of finished products, the company adheres to the highest standards to ensure that its furnaces consistently meet or exceed customer expectations. As a result, Best Superbmelt Furnace Factory has gained recognition as a trusted provider of reliable and durable furnace systems.In addition to its unwavering commitment to quality, Best Superbmelt Furnace Factory is also dedicated to environmental sustainability. The company recognizes the importance of minimizing its environmental impact and has taken proactive steps to develop furnaces that are energy-efficient and eco-friendly. By incorporating advanced technologies and sustainable practices into its manufacturing processes, Best Superbmelt Furnace Factory is helping its customers reduce their carbon footprint while also lowering their operational costs.Best Superbmelt Furnace Factory's exceptional track record and industry leadership have not gone unnoticed. The company has earned numerous accolades and certifications, further validating its position as a top-tier manufacturer of industrial furnaces. With a strong emphasis on continuous improvement, Best Superbmelt Furnace Factory remains at the forefront of innovation, constantly pushing boundaries to develop new and improved furnace solutions.Looking ahead, Best Superbmelt Furnace Factory is poised to further expand its presence in the global market. The company plans to leverage its expertise and reputation to reach new customers and industries, offering its advanced furnace systems to a wider audience. By staying true to its core values of quality, innovation, and customer satisfaction, Best Superbmelt Furnace Factory is well-positioned to continue its upward trajectory and remain a leading force in the field of industrial furnaces.In conclusion, Best Superbmelt Furnace Factory has established itself as a premier manufacturer of industrial furnaces, known for its commitment to quality, innovation, and customer satisfaction. With a dedication to research and development, a focus on environmental sustainability, and a track record of excellence, the company is well-equipped to lead the industry into the future. As Best Superbmelt Furnace Factory continues to expand its global footprint, it is set to deliver its high-performance furnace solutions to a growing base of satisfied customers.

New Electric Crucible Introduces Revolutionary Technology for Efficient Melting" --> "Revolutionary Technology for Efficient Melting Unveiled with Electric Crucible

Title: Pioneering Electric Crucible Transforms the Manufacturing IndustryIntroduction: In a groundbreaking development, an innovative electric crucible has emerged, offering a cutting-edge solution for the manufacturing industry. With its advanced technology and groundbreaking features, this electric crucible, developed by a leading materials research company, promises to revolutionize manufacturing processes, enabling greater efficiency, sustainability, and precision. Electric Crucible: Redefining Manufacturing The newly unveiled electric crucible is poised to redefine manufacturing by offering an unparalleled level of control and flexibility. Traditionally, metal casting and materials processing have heavily relied on fossil fuel-powered crucibles, resulting in significant environmental impacts and limited precision. However, this pioneering electric crucible brings forth multiple advancements poised to overcome these challenges.Sustainable Manufacturing with Lower Environmental ImpactOne of the most significant advantages of adopting this electric crucible technology is its reduced environmental impact. By eliminating the need for fossil fuel combustion, the electric crucible drastically reduces greenhouse gas emissions, contributing to a cleaner and more sustainable manufacturing process. This exciting development comes at a time when industries worldwide are exploring sustainable practices, making this electric crucible the prime choice for environmentally-conscious manufacturers.Enhanced Precision and EfficiencyIn addition to its environmental benefits, the electric crucible also offers unparalleled precision and efficiency. The technology harnesses state-of-the-art heating elements and computer-controlled systems, allowing manufacturers to achieve a higher level of precision in temperature control. This precise control over temperature ensures consistent and uniform heating, minimizing material waste and increasing overall manufacturing efficiency. Furthermore, the electric crucible's design allows for swift and accurate changes in production volume, making it ideal for industries with rapidly changing demands.Real-Time Monitoring and Safety FeaturesAccompanying its advanced heating technology, the electric crucible also includes real-time monitoring capabilities and cutting-edge safety features. These additional features ensure optimal performance and safeguard against potential accidents. The real-time monitoring system provides continuous updates on temperature, pressure, and other crucial parameters, enabling manufacturers to maintain process control and make necessary adjustments when required. Furthermore, the electric crucible includes built-in safety measures to prevent overheating or material spillage, reducing the risk of accidents and enhancing overall workplace safety.Smart Integration and CompatibilityApart from its innovative features, the electric crucible can seamlessly integrate with existing manufacturing systems. Its compatibility with various production lines and automation solutions ensures a hassle-free adoption process for manufacturers. By eliminating the need for a complete overhaul of manufacturing infrastructure, this crucible minimizes downtime and reduces implementation costs, garnering significant interest from industry leaders.Future Prospects and Industry ImplicationsThe introduction of the electric crucible marks a significant milestone in the manufacturing industry, unlocking a myriad of possibilities for future advancements. With greater precision, enhanced energy efficiency, and reduced environmental impact, manufacturers can achieve higher productivity levels while prioritizing sustainability. Furthermore, this crucible's compatibility with automation solutions paves the way for increased integration of Industry 4.0 technologies, boosting overall manufacturing efficiency and competitiveness.ConclusionThe unveiling of the electric crucible signifies a paradigm shift in the manufacturing industry, providing a transformative solution that combines sustainability, efficiency, and precision. With its cutting-edge technology, reduced environmental impact, and seamless integration capabilities, this pioneering innovation promises to reshape manufacturing processes and propel industries towards a more sustainable future. As manufacturers embrace the electric crucible, a new era of enhanced manufacturing awaits, revolutionizing the production landscape across the globe.

Electric Furnace Copper Melting Factories in China - What You Need to Know

China Electric Furnace Melting Copper Factories Take Steps to Improve Efficiency and Environmental ImpactIn recent years, China has seen a significant increase in the number of electric furnace melting copper factories. These factories rely on electric furnaces to melt and refine copper, a process that is more energy-efficient and environmentally friendly compared to traditional methods. With the growing demand for copper in various industries, these factories play a crucial role in meeting this demand while also striving to minimize their impact on the environment.One of the leading companies in this industry, [Company Name], has been at the forefront of innovation and sustainability in electric furnace melting copper production. The company's state-of-the-art facilities and advanced technologies have enabled them to improve efficiency, reduce emissions, and uphold the highest standards of quality in their copper products.In line with the Chinese government's push for cleaner and more sustainable industrial practices, [Company Name] has recently implemented several initiatives aimed at further improving the efficiency and environmental impact of their electric furnace melting copper factories.Firstly, the company has invested in upgrading their electric furnaces to the latest, most energy-efficient models. These modern furnaces are equipped with advanced controls and monitoring systems that optimize the melting process, minimize energy consumption, and reduce greenhouse gas emissions. By investing in these upgrades, [Company Name] is not only able to improve their operational efficiency but also reduce their carbon footprint.In addition to upgrading their furnaces, [Company Name] has also implemented a comprehensive recycling program within their factories. Copper recycling is a key component of sustainable production, as it not only reduces the need for new copper mining but also minimizes waste and environmental impact. By recycling scrap copper and other materials, [Company Name] is able to maximize the utilization of resources and minimize the amount of waste generated during the copper production process.Furthermore, [Company Name] has made significant investments in pollution control and waste treatment technologies. The company has installed advanced air and water purification systems to ensure that their factories operate within strict environmental guidelines. By effectively managing and treating emissions and waste, [Company Name] is able to minimize their impact on local ecosystems and communities.Moreover, [Company Name] has also placed a strong emphasis on workforce training and education regarding environmental sustainability. The company has implemented comprehensive training programs to ensure that their employees are well-versed in sustainable practices and are actively involved in maintaining a clean and environmentally responsible work environment.In addition to their internal initiatives, [Company Name] actively collaborates with industry partners, academic institutions, and government agencies to drive innovation and best practices in electric furnace melting copper production. Through these collaborations, the company is able to stay abreast of the latest technological advancements and contribute to the ongoing development of sustainable solutions for the industry.The efforts of [Company Name] and other electric furnace melting copper factories in China reflect a growing commitment to sustainable and responsible industrial practices. By investing in advanced technologies, implementing recycling programs, and prioritizing environmental stewardship, these factories are setting new standards for the production of copper and other industrial materials.As the demand for copper continues to rise, it is essential for companies in the electric furnace melting copper industry to prioritize sustainability and environmental responsibility. By taking proactive measures to improve efficiency and minimize their environmental impact, companies like [Company Name] are not only securing their position as industry leaders but also contributing to a cleaner and more sustainable future for the copper industry as a whole.

Top Zinc Melting Furnace Factories: Discover the Best Manufacturers in the Industry

Title: Advancements in Zinc Melting Furnace Technology Revolutionize the IndustryIntroduction:Zinc melting furnace factories play a crucial role in the manufacturing process of various industries, including automotive, construction, and electronics. These factories are responsible for melting and refining zinc to its molten form, which is then used for various applications. With technological advancements, several manufacturers have made significant strides in improving these furnaces' efficiency, safety, and environmental impact. In this article, we explore the recent developments in zinc melting furnace technology and their impact on the industry.1. Enhanced Efficiency through Innovative Designs:Leading zinc melting furnace manufacturers have been focusing on improving efficiency to meet the growing demands of zinc-consuming industries. They have developed advanced designs that optimize heat transfer, resulting in faster and more efficient melting processes. These innovative designs utilize various methods such as induction heating, electric resistive heating, or fossil fuel combustion to achieve optimal melting conditions.Furthermore, precise temperature control mechanisms and advanced insulation materials have been integrated into these furnaces, minimizing heat loss and enabling uniform melting throughout the entire process. As a result, manufacturers can achieve higher throughput capacities while reducing energy consumption, ultimately leading to cost savings and increased productivity.2. Emphasis on Safety Measures:Ensuring worker safety is of utmost importance in zinc melting furnace factories. Recent advancements have brought forth enhanced safety features, making the operating environment safer for workers. Furnaces now come equipped with sensor-based systems that continuously monitor various parameters like temperature, pressure, and gas leakage. In the event of any abnormalities or hazardous situations, these systems can automatically shut down the furnace or trigger alarms, thereby preventing accidents and ensuring a secure work environment.Moreover, improved ventilation and exhaust systems have been implemented to minimize the health risks associated with exposure to metal fumes and other harmful byproducts generated during the melting process. These advancements have significantly reduced the health hazards for workers, leading to improved overall well-being and better work conditions.3. Environmental Sustainability:Zinc melting furnace factories have made notable progress in reducing their environmental footprint. Manufacturers have adopted cleaner and more sustainable energy sources, such as electricity from renewable sources or use of cleaner fuels like natural gas, minimizing greenhouse gas emissions. Additionally, advanced filtration systems have been introduced to capture and treat harmful byproducts like particulate matter, sulfur dioxide, and nitrogen oxides generated during the melting process.Furthermore, recycling initiatives have gained momentum, allowing for the recycling and reuse of zinc scrap and dross generated during the manufacturing process. This significantly reduces waste disposal, conserves natural resources, and promotes a circular economy approach.Conclusion:Recent advancements in zinc melting furnace technology have revolutionized the industry, bringing forth numerous benefits such as enhanced efficiency, improved safety measures, and a reduced environmental impact. The integration of innovative designs, refined temperature control mechanisms, and advanced safety features have enabled manufacturers to achieve higher productivity while safeguarding the well-being of workers. Moreover, the adoption of sustainable practices, including the use of cleaner energy sources and recycling initiatives, have promoted environmental sustainability within the industry.As the demand for zinc in various industries continues to grow, it is encouraging to witness the continuous efforts made by zinc melting furnace factories to push the boundaries of technological innovation. These advancements not only contribute to the industry's growth but also address the pressing concerns of efficiency, safety, and sustainability.

Guide to Induction Melting Metal for Efficient Metal Processing

Title: Induction Melting Technology Revolutionizes Metal Processing - A Game-Changer in Manufacturing IndustriesIntroduction (100 words):In the realm of metal processing, innovative technologies have consistently played a vital role in driving progress and efficiency. One such groundbreaking invention is induction melting technology - an advanced, high-performance method designed to enhance metal melting and refining processes. Developed and perfected by {company name}, this cutting-edge technique is revolutionizing the manufacturing industry. This news article will delve into the intricacies of induction melting, its various applications, and the extensive benefits it offers to businesses across different sectors.Section 1: The Power of Induction Melting for Metal Processing (200 words)Since its introduction, induction melting technology has transformed the way metals are melted and processed. Utilizing electromagnetic induction, this technique employs an alternating current to generate a magnetic field that induces eddy currents within the metal product being melted. These eddy currents, in turn, produce heat due to resistance, leading to the melting of the metal.One of the primary advantages of induction melting is its ability to achieve high melting rates. Compared to traditional melting methods, induction melting proves to be significantly faster and more energy-efficient. This technology also ensures uniform heating, preventing hot spots or inconsistencies in the metal surface, resulting in a higher-quality end product.Section 2: Applications of Induction Melting (250 words)The versatility of induction melting makes it applicable to a broad range of industries. From small-scale foundries and metalworking companies to larger manufacturing plants, this technology has become indispensable across many sectors.In the automotive industry, induction melting has revolutionized the production of critical engine components such as pistons, cylinders, and crankshafts. Through high-precision melting and alloying, this advanced method enhances the durability, strength, and performance of these vital automotive parts.Additionally, the aerospace industry benefits greatly from induction melting technology. From constructing turbine blades to manufacturing aircraft parts, the rapid heating and precise temperature control offered by this technique ensures the production of lightweight, high-strength, and heat-resistant components.Other sectors, such as jewelry manufacturing, electrical equipment manufacturing, and metal recycling, have all turned to induction melting for its accuracy, speed, and cost-efficiency. The process is easily customizable to cater to specific melting requirements, making it an ideal choice for various metallurgical applications.Section 3: {Company Name} - A Pioneer in Induction Melting Technology (200 words){Company Name} has established itself as a frontrunner in the field of induction melting, relentlessly pushing boundaries and setting new standards for metal processing. With years of research and development, the company has perfected their advanced induction melting equipment and machines - removing thermal inefficiencies and enhancing energy utilization.The company's range of induction melting systems offers flexibility, efficiency, and unmatched performance. These systems are designed to melt different types of metals, including steel, iron, aluminum, and precious metals, enabling businesses to harness the full potential of induction melting technology.Moreover, {Company Name} provides comprehensive training and support to ensure seamless integration of the technology into existing manufacturing processes. They have also introduced user-friendly interfaces and automated features to simplify operation and maximize productivity.Conclusion (150 words):Induction melting technology has truly revolutionized metal processing, providing an unparalleled solution for businesses seeking enhanced efficiency and quality in their manufacturing processes. With its ability to achieve uniform heating, precise control, and remarkable energy efficiency, this technology is instrumental in shaping the future of various industries. {Company Name}'s expertise and innovation continue to drive the advancements and adoption of this groundbreaking technology, cementing its role as a pioneer in the field.By harnessing the power of induction melting technology, businesses can optimize their operations, reduce costs, and deliver superior products to meet the ever-growing demands of the modern market. As the manufacturing industry continues to evolve, induction melting stands as a testament to the transformative capabilities of technology in shaping progress and growth.