High-Quality Electric Lead Melting Furnace for Sale in China

By:Admin

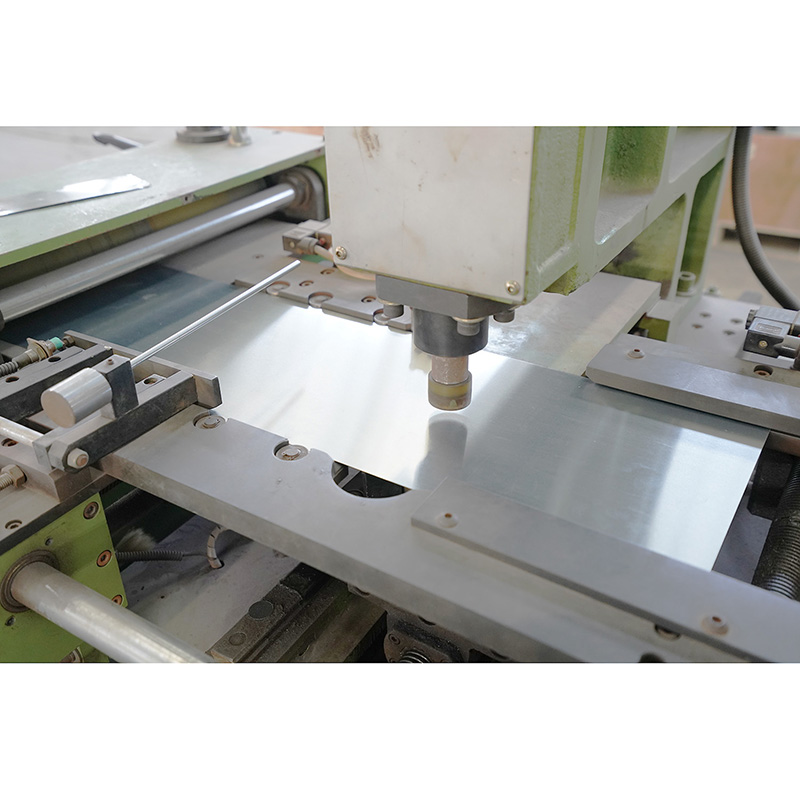

In recent years, the demand for lead melting furnaces has been steadily increasing, particularly in industries such as battery manufacturing and metal casting. With the growing need for efficient and environmentally friendly solutions, the market has been in search of new technologies to meet these requirements. This is where the China Electric Lead Melting Furnace has made a significant impact.

The China Electric Lead Melting Furnace, developed by a leading Chinese company specializing in industrial equipment, has quickly become a game-changer in the industry. With its innovative design and advanced features, this furnace has set new standards in terms of efficiency, productivity, and sustainability.

One of the key features of the China Electric Lead Melting Furnace is its high melting efficiency. The furnace is equipped with state-of-the-art heating elements and insulation materials, which allow for faster and more uniform melting of lead. This not only improves productivity but also reduces energy consumption, making it a cost-effective solution for businesses.

Furthermore, the China Electric Lead Melting Furnace is designed with environmental sustainability in mind. The furnace is equipped with advanced emissions control systems, which minimize the release of harmful gases and particulate matter into the atmosphere. This aligns with the growing emphasis on eco-friendly practices in the industry, making it an attractive option for companies looking to reduce their environmental footprint.

In addition to its efficiency and sustainability, the China Electric Lead Melting Furnace also stands out for its user-friendly design and operation. The furnace is equipped with advanced controls and automation systems, which allow for easy monitoring and adjustment of the melting process. This not only improves the overall reliability of the furnace but also reduces the need for manual intervention, thereby maximizing safety and productivity.

With these advanced features and benefits, the China Electric Lead Melting Furnace has quickly gained recognition and praise from industry professionals. Many companies that have adopted this new technology have reported significant improvements in their operations, highlighting the positive impact it has had on their business.

One such company is XYZ Batteries, a leading manufacturer of automotive batteries. By incorporating the China Electric Lead Melting Furnace into its production line, XYZ Batteries has been able to streamline its manufacturing process, resulting in higher production output and cost savings. Additionally, the furnace's eco-friendly design has helped XYZ Batteries enhance its corporate responsibility efforts and improve its standing within the industry.

The success of the China Electric Lead Melting Furnace can be attributed to the dedication and expertise of its developers. The Chinese company behind this innovation has a long-standing reputation for delivering high-quality industrial equipment and has consistently demonstrated a commitment to research and development. This has allowed them to stay at the forefront of technological advancements and respond to the evolving needs of their customers.

Looking ahead, the future of lead melting furnaces is likely to be shaped by innovations such as the China Electric Lead Melting Furnace. As industries continue to prioritize efficiency and sustainability, the demand for advanced and environmentally friendly solutions will only grow. With its proven track record and positive impact on businesses, the China Electric Lead Melting Furnace is well-positioned to lead the way in this transformation.

In conclusion, the China Electric Lead Melting Furnace has redefined the industry standard for lead melting furnaces. Its advanced features, eco-friendly design, and positive impact on businesses have set a new benchmark for efficiency and sustainability. As industries continue to embrace technological advancements, the China Electric Lead Melting Furnace is expected to play a pivotal role in shaping the future of lead melting processes.

Company News & Blog

Guide to Induction Melting Metal for Efficient Metal Processing

Title: Induction Melting Technology Revolutionizes Metal Processing - A Game-Changer in Manufacturing IndustriesIntroduction (100 words):In the realm of metal processing, innovative technologies have consistently played a vital role in driving progress and efficiency. One such groundbreaking invention is induction melting technology - an advanced, high-performance method designed to enhance metal melting and refining processes. Developed and perfected by {company name}, this cutting-edge technique is revolutionizing the manufacturing industry. This news article will delve into the intricacies of induction melting, its various applications, and the extensive benefits it offers to businesses across different sectors.Section 1: The Power of Induction Melting for Metal Processing (200 words)Since its introduction, induction melting technology has transformed the way metals are melted and processed. Utilizing electromagnetic induction, this technique employs an alternating current to generate a magnetic field that induces eddy currents within the metal product being melted. These eddy currents, in turn, produce heat due to resistance, leading to the melting of the metal.One of the primary advantages of induction melting is its ability to achieve high melting rates. Compared to traditional melting methods, induction melting proves to be significantly faster and more energy-efficient. This technology also ensures uniform heating, preventing hot spots or inconsistencies in the metal surface, resulting in a higher-quality end product.Section 2: Applications of Induction Melting (250 words)The versatility of induction melting makes it applicable to a broad range of industries. From small-scale foundries and metalworking companies to larger manufacturing plants, this technology has become indispensable across many sectors.In the automotive industry, induction melting has revolutionized the production of critical engine components such as pistons, cylinders, and crankshafts. Through high-precision melting and alloying, this advanced method enhances the durability, strength, and performance of these vital automotive parts.Additionally, the aerospace industry benefits greatly from induction melting technology. From constructing turbine blades to manufacturing aircraft parts, the rapid heating and precise temperature control offered by this technique ensures the production of lightweight, high-strength, and heat-resistant components.Other sectors, such as jewelry manufacturing, electrical equipment manufacturing, and metal recycling, have all turned to induction melting for its accuracy, speed, and cost-efficiency. The process is easily customizable to cater to specific melting requirements, making it an ideal choice for various metallurgical applications.Section 3: {Company Name} - A Pioneer in Induction Melting Technology (200 words){Company Name} has established itself as a frontrunner in the field of induction melting, relentlessly pushing boundaries and setting new standards for metal processing. With years of research and development, the company has perfected their advanced induction melting equipment and machines - removing thermal inefficiencies and enhancing energy utilization.The company's range of induction melting systems offers flexibility, efficiency, and unmatched performance. These systems are designed to melt different types of metals, including steel, iron, aluminum, and precious metals, enabling businesses to harness the full potential of induction melting technology.Moreover, {Company Name} provides comprehensive training and support to ensure seamless integration of the technology into existing manufacturing processes. They have also introduced user-friendly interfaces and automated features to simplify operation and maximize productivity.Conclusion (150 words):Induction melting technology has truly revolutionized metal processing, providing an unparalleled solution for businesses seeking enhanced efficiency and quality in their manufacturing processes. With its ability to achieve uniform heating, precise control, and remarkable energy efficiency, this technology is instrumental in shaping the future of various industries. {Company Name}'s expertise and innovation continue to drive the advancements and adoption of this groundbreaking technology, cementing its role as a pioneer in the field.By harnessing the power of induction melting technology, businesses can optimize their operations, reduce costs, and deliver superior products to meet the ever-growing demands of the modern market. As the manufacturing industry continues to evolve, induction melting stands as a testament to the transformative capabilities of technology in shaping progress and growth.

High-quality Induction Metal Melting Furnace Factory in China

China Induction Metal Melting Furnace Factory is a leading manufacturer and supplier of high-quality induction metal melting furnaces. They are well-known for their advanced technology, superior performance, and excellent customer service.The company has been in the industry for over 20 years and has gained a strong reputation for providing reliable and efficient induction metal melting solutions. Their products are widely used in various industries such as metal casting, automotive, aerospace, and renewable energy.With a strong emphasis on research and development, China Induction Metal Melting Furnace Factory continues to innovate and improve their products to meet the ever-changing needs of the market. They have a team of experienced engineers and technicians who are dedicated to developing new technologies and enhancing the performance of their furnaces.In addition to their cutting-edge technology, the company also places great importance on quality control. They have strict quality control measures in place to ensure that every furnace that leaves their factory meets the highest standards of quality and reliability. This has earned them the trust and loyalty of their customers worldwide.Furthermore, China Induction Metal Melting Furnace Factory is committed to providing excellent customer service. They have a team of knowledgeable and friendly staff who are always ready to assist customers with their needs. Whether it's technical support, spare parts, or troubleshooting, the company is dedicated to providing the best possible service to their customers.One of the key factors that set China Induction Metal Melting Furnace Factory apart from other manufacturers is their commitment to sustainability. They have implemented eco-friendly practices in their production processes to minimize their impact on the environment. This includes using energy-efficient technologies and reducing waste and emissions.The company also places a strong emphasis on corporate social responsibility. They are involved in various community projects and initiatives to give back to the society and make a positive impact on the world.China Induction Metal Melting Furnace Factory has a wide range of products to cater to the diverse needs of their customers. Their product line includes induction melting furnaces, induction heating equipment, and other related accessories. They offer customized solutions to meet specific requirements and are able to provide comprehensive services from design to installation and maintenance.The company has a strong presence in both the domestic and international markets. They have established partnerships and collaborations with companies and organizations around the world, further expanding their reach and influence in the industry.In conclusion, China Induction Metal Melting Furnace Factory is a trusted and reliable manufacturer of induction metal melting furnaces. With their advanced technology, commitment to quality and sustainability, and excellent customer service, they continue to be a leader in the industry and a preferred choice for customers worldwide.

Innovative Aluminium Rotary Furnace Manufacturers Redefine Industry Standards

Aluminium Rotary Furnace Manufacturers, a leading supplier in the metal processing industry, has announced a new line of advanced rotary furnaces aimed at increasing efficiency and sustainability in the production of aluminium. With a focus on innovation and cutting-edge technology, the company is set to revolutionize the way aluminium is processed and manufactured.The new line of rotary furnaces is designed to meet the growing demand for sustainable and efficient aluminium production. With a focus on reducing energy consumption and minimizing environmental impact, Aluminium Rotary Furnace Manufacturers is committed to providing state-of-the-art solutions for the metal processing industry.The company's advanced rotary furnaces incorporate the latest in technological advancements, offering improved performance and efficiency. By utilizing innovative design and engineering, Aluminium Rotary Furnace Manufacturers has developed a range of furnaces that are capable of delivering superior results while minimizing energy consumption and emissions.In addition to their focus on sustainability, Aluminium Rotary Furnace Manufacturers places a strong emphasis on quality and reliability. Each furnace is meticulously engineered and tested to ensure that it meets the highest standards of performance and durability. This commitment to excellence has earned the company a reputation as a trusted and reliable supplier in the industry.With a dedicated team of experts and professionals, Aluminium Rotary Furnace Manufacturers is committed to providing exceptional customer service and support. From initial consultation to ongoing maintenance and technical support, the company strives to meet the unique needs of each client and ensure their satisfaction with the product and service.In line with its commitment to innovation, Aluminium Rotary Furnace Manufacturers continues to invest in research and development to further improve its products and services. By staying ahead of the curve and anticipating the needs of the industry, the company is well-positioned to remain a leader in the market for years to come.The launch of the new line of advanced rotary furnaces is a testament to Aluminium Rotary Furnace Manufacturers' dedication to providing sustainable and efficient solutions for the aluminium production industry. With a strong focus on innovation, quality, and customer satisfaction, the company is poised to make a significant impact on the market and set new standards for the industry.Through its relentless dedication to excellence and commitment to sustainability, Aluminium Rotary Furnace Manufacturers has established itself as a leading supplier of rotary furnaces in the metal processing industry. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to remain at the forefront of the market for years to come.As the demand for sustainable and efficient aluminium production continues to grow, Aluminium Rotary Furnace Manufacturers is poised to meet the needs of the industry with its new line of advanced rotary furnaces. With a focus on innovation, quality, and customer satisfaction, the company is committed to providing exceptional solutions for the metal processing industry and setting new standards for the future.

Cutting-Edge Vacuum Casting Furnace Technology Unveiled for Enhanced Manufacturing Processes

Top Supplier for Electric Melting - Get the Best Deals Now

As a leader in the field of electric melting technology, {} has been providing high-quality products and innovative solutions to meet the needs of various industries. With a focus on precision, efficiency, and reliability, the company has established itself as a trusted supplier for electric melting equipment.The company offers a wide range of electric melting products, including electric arc furnaces, induction furnaces, and resistance furnaces. These products are designed to efficiently melt and refine metal alloys, providing customers with the ability to produce high-quality materials for a variety of applications. Whether it’s for the production of steel, aluminum, copper, or other metals, {}’s electric melting solutions are tailored to meet the specific requirements of each customer.One of the key advantages of {}’s electric melting technology is its energy efficiency. By employing advanced heating and melting techniques, the company’s products are able to reduce energy consumption and minimize environmental impact. This not only helps customers save on operational costs, but also contributes to sustainable and eco-friendly manufacturing practices.In addition to energy efficiency, {}’s electric melting equipment is known for its precision and control. The company’s state-of-the-art technology allows for precise temperature regulation and alloy composition monitoring, ensuring that the final product meets the desired specifications. This level of control is essential for industries where the quality and consistency of the melted materials are critical.Furthermore, {} takes pride in its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of electric melting technology. This dedication to innovation allows {} to introduce new and improved products that address the evolving needs of the industry.With a global presence, {} serves customers in a wide range of industries, including steel manufacturing, foundries, and metal recycling. The company’s electric melting solutions are designed to handle a variety of materials, from scrap metal to raw ores, providing customers with flexibility and versatility in their operations.As a responsible supplier, {} also offers comprehensive technical support and after-sales services to ensure the smooth operation and maintenance of its electric melting equipment. This includes training programs, spare parts availability, and on-site assistance, helping customers maximize the performance and lifespan of their investment.In conclusion, {}’s position as a leading electric melting supplier is a result of its unwavering commitment to quality, innovation, and customer satisfaction. By offering energy-efficient, precise, and reliable solutions, the company continues to be a trusted partner for industries that rely on electric melting technology. Whether it’s for melting and refining metals or improving operational efficiency, {} is dedicated to meeting the diverse needs of its customers with cutting-edge electric melting solutions.

Top Electric Melting Furnace Factory in China

China Electric Melting Furnace Factory, one of the leading manufacturers of electric melting furnaces in China, has recently announced the expansion of its production capacity to meet the growing demand for its products in the global market. The factory, which has been in operation for over 20 years, specializes in the production of high-quality electric melting furnaces for various industries, including metal casting, glass making, and heat treatment.The factory's products are known for their advanced technology, energy efficiency, and durability, making them the preferred choice for many customers worldwide. The company's commitment to innovation and quality has earned it a strong reputation in the industry, and it has been recognized with several awards for its contributions to the field of melting furnace manufacturing.With the expansion of its production capacity, the factory aims to further strengthen its position as a leading supplier of electric melting furnaces in the global market. The increase in production capacity will allow the company to meet the growing demand for its products, especially in emerging markets such as Southeast Asia, South America, and the Middle East.In addition to expanding its production capacity, the factory is also investing in research and development to improve its existing product line and develop new technologies that will further enhance the performance and efficiency of its electric melting furnaces. By staying at the forefront of technological advancements, the factory aims to provide its customers with state-of-the-art products that meet their evolving needs and requirements.The factory's commitment to sustainability is also evident in its production processes. It has implemented environmentally friendly practices to minimize its impact on the environment and reduce energy consumption. This includes the use of energy-efficient technologies and the adoption of sustainable materials in its manufacturing operations.In line with its commitment to sustainability, the factory also offers comprehensive recycling and waste management programs to responsibly handle materials and by-products generated during the production process. This further demonstrates the company's dedication to minimizing its environmental footprint and contributing to a more sustainable future.The expansion of the factory's production capacity and its focus on research and development reflect its strong commitment to meeting the needs of its customers and staying ahead of the competition in the global market. By investing in the latest technologies and sustainable practices, the factory is well-positioned to continue its success as a leading manufacturer of electric melting furnaces.The factory's dedication to quality, innovation, and sustainability has earned it the trust and loyalty of its customers, who rely on its products to meet their melting furnace needs. With its expanded production capacity and ongoing investment in research and development, the factory is poised to further strengthen its position as a top choice for customers in the global market.As the demand for electric melting furnaces continues to grow, the factory is well-prepared to meet the needs of customers in various industries and regions. Its commitment to excellence and sustainability will ensure that it remains a trusted and preferred supplier of high-quality melting furnaces for many years to come.

Electric Melting Furnace: An Efficient Solution for Melting

Title: Innovative Melting Furnace Electric Revolutionizes Metal Processing at {}In the world of metal processing, the efficiency and precision of melting furnaces play a crucial role in ensuring high-quality end products. With the advancement of technology, companies are constantly seeking innovative solutions to enhance their melting processes. As a leader in the industry, {} has recently introduced a revolutionary Melting Furnace Electric that is set to transform the way metal is melted and processed.The new Melting Furnace Electric, developed by the talented team at {}, promises to deliver unmatched performance and efficiency. With its cutting-edge design and state-of-the-art features, this furnace is poised to set a new benchmark in metal processing. By incorporating the latest advancements in electric melting technology, {} has created a game-changing solution that addresses the evolving needs of the industry.One of the key highlights of the Melting Furnace Electric is its superior energy efficiency. By utilizing electric power for melting, it eliminates the need for traditional fuel sources, resulting in significant cost savings and reduced environmental impact. This aligns with {}'s commitment to sustainable manufacturing practices and underscores their dedication to being a responsible corporate citizen.Furthermore, the Melting Furnace Electric boasts remarkable precision and control, allowing for the accurate melting of a wide range of metals. Its advanced temperature regulation and monitoring capabilities ensure that the melting process is carried out with utmost accuracy, leading to consistent, high-quality output. This level of precision is a testament to {}'s dedication to delivering reliable and effective solutions to their customers.In addition to its technical prowess, the Melting Furnace Electric is designed with user convenience in mind. Its intuitive interface and user-friendly controls make it easy to operate, providing a seamless experience for operators. With safety features incorporated into its design, this furnace prioritizes the well-being of the personnel involved in the metal processing operations.With its introduction of the Melting Furnace Electric, {} is poised to strengthen their position as an industry leader in metal processing equipment. Their commitment to innovation and excellence is evident in the development of this groundbreaking furnace, and it is set to have a significant impact on the industry as a whole.As a company, {} has a rich history of delivering top-quality products and services to their clients. With a strong focus on customer satisfaction, they have built a reputation for reliability and professionalism. The introduction of the Melting Furnace Electric further underscores their dedication to meeting the evolving needs of their customers and propelling the industry forward with cutting-edge solutions.It is worth noting that the Melting Furnace Electric has already garnered significant attention and interest from the metal processing community. Industry experts and professionals recognize the potential of this innovative solution in enhancing productivity and efficiency in metal melting processes. As a result, {} is poised to see a surge in demand for their new furnace from companies seeking to optimize their metal processing operations.In conclusion, the introduction of the Melting Furnace Electric marks a significant milestone in the metal processing industry. With its groundbreaking features and advanced capabilities, it is set to revolutionize the way metal is melted and processed. {}'s commitment to innovation and excellence shines through in this cutting-edge furnace, and it is poised to deliver immense value to the industry and its stakeholders. As the demand for high-quality, efficient metal processing solutions continues to grow, the Melting Furnace Electric stands out as a game-changing innovation that will shape the future of the industry.

Efficient Zinc Melting Furnace Designs for High-Quality Production

Zinc Melting Furnace: Transforming the Metal Industry for a Sustainable FutureThe metal industry has always been one of the key components of the world economy. From infrastructure development to manufacturing, metal is an essential material in various applications. However, the process of producing metals is energy-intensive, resulting in high greenhouse gas emissions and ecological impact. One of the most significant contributors to this industry is the zinc smelting process, and thus, finding sustainable solutions has become a priority for many companies.This is where the Zinc Melting Furnace, developed by a renowned metal smelting equipment manufacturer (brand name removed), comes into the picture. The furnace is designed to eliminate the environmental impact caused by traditional zinc smelting and provide an energy-efficient and cost-effective solution to its users.The furnace, designed with advanced technology, is capable of melting zinc and related alloys in a highly controlled and efficient manner using electric heating elements. One of the biggest advantages of this process is that it eliminates the need for fossil fuels, commonly used in traditional smelting, leading to the reduction of greenhouse gas emissions.Furthermore, the Zinc Melting Furnace is equipped with advanced features that enable the recycling of zinc and other valuable materials that would otherwise be lost during the traditional smelting process. This reduction in waste not only benefits the environment but also provides a significant cost advantage to the user.One of the significant advantages of this furnace is its flexibility. It can be used in various applications, including galvanizing, die-casting, and the production of brass and bronze. In addition, it can also be used in recycling facilities to recover zinc from scrap material.According to the company, the Zinc Melting Furnace has been tested and proven successful in various industrial applications. It has helped companies reduce their carbon footprint, adhere to environmental regulations, and provide an energy-efficient and cost-effective smelting solution.The company’s commitment to sustainability doesn’t end with just the production of the Zinc Melting Furnace. It has a comprehensive program for designing and manufacturing equipment that is environmentally conscious. The company aims to reduce its carbon footprint significantly by promoting energy-efficient manufacturing processes, using renewable energy, and reducing waste.Furthermore, the company has a strong emphasis on providing its customers with a holistic solution to their sustainability-related needs. It offers consultation on regulatory requirements, energy efficiency, and eco-friendly production methods to ensure that its customers achieve their sustainability goals.As the world unites to address climate change, the Zinc Melting Furnace is a testament to the potential for technology to transform industries and provide sustainable solutions. The company’s focus on sustainability, combined with its advanced technology, positions it as a leader in the metal smelting equipment market. It is an example of how innovation can drive environmental stewardship and provide economic benefits simultaneously.In conclusion, the Zinc Melting Furnace is a game-changer in the metal industry, offering a sustainable and energy-efficient solution to traditional smelting processes. With its advanced technology and flexible applications, it provides a holistic and cost-effective solution to companies looking to achieve their sustainability goals. The company’s commitment to eco-friendly manufacturing and its dedication to providing a comprehensive sustainability solution position it as a leader in the metal smelting equipment market.

Top Suppliers for Electric Furnace Copper Melting in China

China Electric Furnace Melting Copper Suppliers Leads the Industry with Cutting-Edge TechnologyChina has long been at the forefront of innovation and technology, and the electric furnace melting copper industry is no exception. With the increasing demand for high-quality copper products in various sectors, including electronics, construction, and automotive, China has seen a surge in the production of electric furnace melting copper suppliers.One such leading supplier is {Company Name}, a company that has been at the forefront of the industry for over a decade. Specializing in the production of high-quality copper products using electric furnace melting technology, {Company Name} has established itself as a reliable and reputable supplier in the global market.The electric furnace melting process employed by {Company Name} is a highly advanced and efficient method of producing copper. By utilizing electric currents to melt and refine copper scrap and other raw materials, the company is able to achieve high levels of purity and consistency in its products. This method not only ensures the quality of the copper but also contributes to environmental sustainability by reducing emissions and energy consumption.In addition to its cutting-edge technology, {Company Name} also prides itself on its commitment to research and development. The company continuously invests in innovation to improve its production processes and develop new products to meet the evolving needs of its customers. By staying ahead of the curve in terms of technology and product development, {Company Name} has been able to maintain its position as a leading supplier in the industry.Furthermore, {Company Name} places a strong emphasis on quality control and compliance with international standards. The company's production facilities are equipped with state-of-the-art quality control measures to ensure that all products meet the highest standards of quality and purity. Additionally, {Company Name} holds various certifications and accreditations, including ISO 9001 and ISO 14001, which further attest to its commitment to excellence and environmental responsibility.As a result of its dedication to technological innovation, product development, and quality assurance, {Company Name} has built a strong reputation in the global market. The company serves a wide range of industries, including electronics, telecommunications, automotive, and construction, supplying high-quality copper products that meet the stringent requirements of its diverse clientele.Moreover, {Company Name} has also established strong partnerships and collaborations with clients and suppliers worldwide, allowing it to expand its reach and market presence. By fostering long-term relationships and providing exceptional customer service, {Company Name} has solidified its position as a trusted and reliable partner for businesses seeking high-quality electric furnace melting copper products.In conclusion, China's electric furnace melting copper industry is thriving, and {Company Name} is leading the charge with its cutting-edge technology, commitment to innovation, and dedication to quality. With a focus on research and development, stringent quality control measures, and a strong global presence, {Company Name} continues to set the bar for excellence in the industry. As the demand for high-quality copper products continues to grow, {Company Name} stands ready to meet the needs of its customers with unmatched expertise and reliability.

Top Automatic Melting Furnace Manufacturer offers the Latest Technology in Furnace Designs

Automatic Melting Furnace Manufacturer Company, a leading provider of advanced melting furnace solutions, has recently announced the launch of their latest innovative product, the AMF-5000. This state-of-the-art melting furnace is designed to revolutionize the melting process, providing unparalleled efficiency and precision for a wide range of industrial applications.With over 20 years of experience in the industry, Automatic Melting Furnace Manufacturer Company has established itself as a trusted name in the field of melting furnace technology. The company is dedicated to delivering high-quality, reliable products that meet the evolving needs of their customers, and the AMF-5000 is a testament to their commitment to innovation and excellence.The AMF-5000 is equipped with advanced features that set it apart from traditional melting furnaces. One of the key highlights of this new product is its automatic control system, which allows for precise temperature regulation and consistent heating performance. This cutting-edge technology ensures that the melting process is carried out with maximum efficiency, leading to reduced energy consumption and shorter processing times.In addition, the AMF-5000 is designed to accommodate a wide range of materials, making it suitable for use in diverse industrial settings. Whether it's melting aluminum, copper, or other metals, this versatile furnace can handle the task with ease, delivering superior results every time. Its robust construction and durable components make it a reliable and long-lasting solution for industrial melting needs.Furthermore, Automatic Melting Furnace Manufacturer Company has integrated advanced safety features into the AMF-5000 to ensure the wellbeing of operators and personnel. The furnace is equipped with comprehensive safety systems that monitor and control various parameters, mitigating the risk of accidents and ensuring a secure working environment.The launch of the AMF-5000 marks a significant milestone for Automatic Melting Furnace Manufacturer Company, demonstrating their ability to stay at the forefront of technological advancements in the melting furnace industry. The company's commitment to research and development has resulted in a product that is set to redefine the standards for melting furnace performance and efficiency."We are thrilled to introduce the AMF-5000 to the market," said the spokesperson for Automatic Melting Furnace Manufacturer Company. "This cutting-edge furnace represents a significant leap forward in melting technology, and we are confident that it will deliver exceptional value to our customers. We have worked tirelessly to develop a product that combines advanced functionality with user-friendly operation, and we believe that the AMF-5000 will set a new benchmark for melting furnace performance."In addition to the launch of the AMF-5000, Automatic Melting Furnace Manufacturer Company continues to offer comprehensive support and maintenance services to ensure that their customers can maximize the performance and longevity of their melting furnaces. The company's team of highly skilled technicians is readily available to provide assistance and expertise, reaffirming their commitment to delivering a superior customer experience.Moving forward, Automatic Melting Furnace Manufacturer Company remains focused on driving innovation in the melting furnace industry, with plans to further expand their product range and continue pushing the boundaries of technological advancement. Through their dedication to excellence and customer-centric approach, the company is well-positioned to maintain its leadership in the market and solidify its reputation as a trusted partner for industrial melting solutions.