Top Induction Melting Furnace for Brass - A Comprehensive Guide

By:Admin

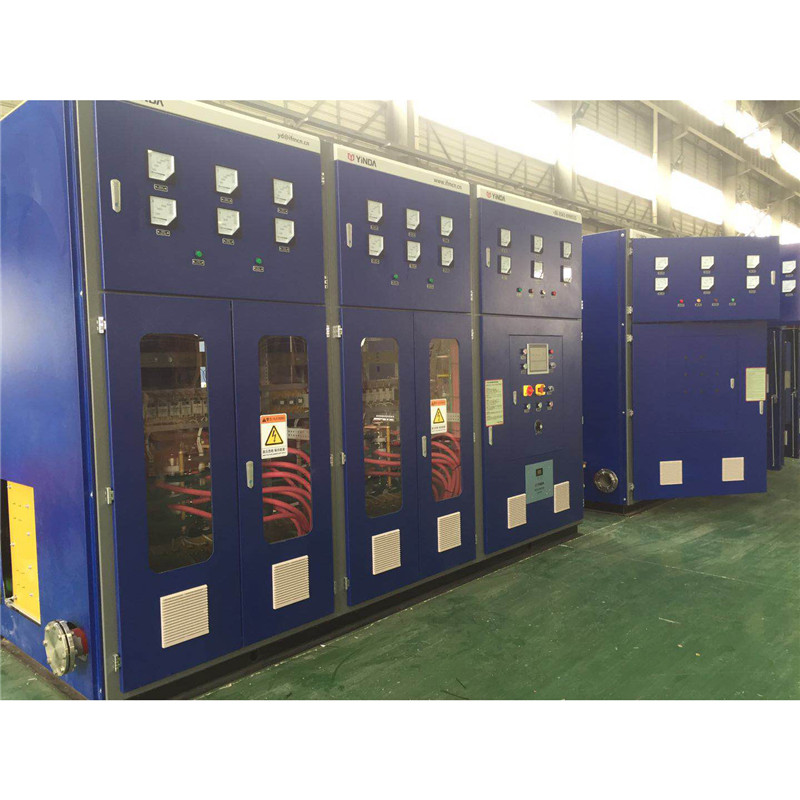

Best Brass Induction Melting Furnace is a leading manufacturer of cutting-edge induction melting furnaces that are designed to cater to the specific needs of brass production. The company has been at the forefront of technological advancements in the field of metal melting and has established a strong reputation for delivering top-notch equipment to its clients.

The induction melting furnaces produced by Best Brass Induction Melting Furnace are renowned for their efficiency, reliability, and precision. These furnaces are capable of melting a wide range of metals, including brass, copper, aluminum, and gold, with unparalleled accuracy and speed. The advanced induction heating technology used in these furnaces ensures that the metal is melted uniformly and without any impurities, resulting in high-quality brass products.

In addition to its cutting-edge technology, Best Brass Induction Melting Furnace takes pride in its commitment to sustainability and environmental responsibility. The company has incorporated energy-efficient features in its induction melting furnaces, making them more eco-friendly and cost-effective to operate. This aligns with the global push towards environmentally conscious manufacturing practices and has made Best Brass Induction Melting Furnace an attractive choice for businesses looking to reduce their carbon footprint.

Furthermore, Best Brass Induction Melting Furnace offers a comprehensive range of services to support its clients in maximizing the performance of their induction melting furnaces. From installation and commissioning to maintenance and technical support, the company provides end-to-end solutions to ensure the seamless operation of its equipment.

The success of Best Brass Induction Melting Furnace can be attributed to its unwavering dedication to innovation and customer satisfaction. The company invests heavily in research and development to stay ahead of the curve and continuously improve its products to meet the evolving needs of the industry. Moreover, Best Brass Induction Melting Furnace values its relationships with clients and strives to provide personalized solutions that address their specific requirements.

As the demand for brass continues to rise, the role of Best Brass Induction Melting Furnace in the industry becomes increasingly vital. The company’s induction melting furnaces are well-equipped to meet the challenges of modern brass production and are poised to play a crucial role in shaping the future of the industry.

In conclusion, Best Brass Induction Melting Furnace’s commitment to technological innovation, environmental sustainability, and customer-centric approach has solidified its position as a leader in the field of metal melting equipment. With its advanced induction melting furnaces and unwavering dedication to excellence, the company is well-positioned to meet the growing demand for high-quality brass products and drive the industry forward.

Company News & Blog

Top Induction Furnace Frequency Supplier: Everything You Need to Know

The demand for high-quality induction furnace frequency suppliers has been steadily increasing in the global market. This is because induction furnace frequency plays a critical role in the efficient operation of induction furnaces, which are widely used in the metal casting and steel manufacturing industries. As such, finding the best induction furnace frequency supplier is crucial for businesses looking to optimize their operational efficiency and output quality.One company that has been gaining recognition as a top induction furnace frequency supplier is {}. With a strong focus on providing innovative and reliable frequency solutions, the company has positioned itself as a trusted partner for businesses in the metal casting and steel manufacturing industries.Established in {}, {} has built a solid reputation for delivering high-performance induction furnace frequency solutions that meet the diverse needs of its clients. The company's commitment to excellence is reflected in its state-of-the-art manufacturing facilities and its team of experienced engineers and technical experts who are dedicated to developing cutting-edge frequency solutions.One of the key factors that set {} apart from other suppliers is its comprehensive range of induction furnace frequency products. The company offers a wide selection of frequency converters, power supplies, and related accessories that are designed to deliver exceptional performance and reliability. This diverse product portfolio allows {} to cater to the specific requirements of different induction furnace applications, providing customers with tailored solutions that meet their unique operational needs.In addition to its product offerings, {} also excels in providing unparalleled customer support and technical assistance. The company takes a customer-centric approach, working closely with clients to understand their challenges and requirements, and offering customized solutions that address their specific needs. This commitment to customer satisfaction has earned {} a loyal client base and a strong reputation for being a reliable and responsive supplier of induction furnace frequency solutions.Furthermore, {} places a strong emphasis on research and development, constantly striving to improve and innovate its frequency solutions. By leveraging the latest technological advancements and industry best practices, the company continues to push the boundaries of what is possible in induction furnace frequency technology, ensuring that its clients have access to the most advanced and efficient solutions on the market.With a global reach and a solid track record of delivering exceptional products and services, {} has firmly established itself as a leading induction furnace frequency supplier. Its commitment to quality, innovation, and customer satisfaction sets it apart in the market and positions it as a preferred partner for businesses in the metal casting and steel manufacturing industries.As the demand for induction furnace frequency solutions continues to grow, companies are increasingly turning to {} for their frequency converter and power supply needs. With a strong focus on delivering high-performance solutions and unparalleled customer support, the company is well-positioned to meet the evolving needs of the industry and continue its success as a top supplier of induction furnace frequency solutions.

Top 5 Rotary Melting Furnace Manufacturers to Consider

Best Rotary Melting Furnace Factories in 2021Rotary melting furnaces are essential equipment in the metallurgical industry for the melting of various metals like aluminum, copper, and zinc. They are widely used in processing industries to efficiently melt scrap metal and recover valuable materials. With the demand for high-quality melting furnaces on the rise, several factories have stepped up their game to meet the market's needs. In this article, we'll explore some of the best rotary melting furnace factories in 2021, including {}. {} is a leading manufacturer of rotary melting furnaces, with a strong reputation for producing high-quality equipment that meets the needs of the industry. The company has been in business for over 30 years and has a strong focus on innovation and continuous improvement. Their rotary melting furnaces are known for their efficiency, reliability, and durability, making them a top choice for many metallurgical companies around the world.{} is another prominent player in the rotary melting furnace industry, known for its commitment to quality and customer satisfaction. The company's melting furnaces are designed to handle a wide range of materials and are built to last, making them an ideal choice for companies looking for long-term investment in their melting equipment.{} is a well-respected name in the industry, with a strong track record of delivering top-notch rotary melting furnaces that meet the highest standards of performance and reliability. The company's dedication to research and development has led to the creation of innovative melting furnace designs that are tailored to the specific needs of the industry.{} is a global leader in the manufacturing of rotary melting furnaces, with a strong focus on delivering cutting-edge technology and superior performance. The company's melting furnaces are known for their energy efficiency and advanced control systems, making them a popular choice for companies looking to maximize productivity while reducing operating costs.In addition to these top players, there are several other rotary melting furnace factories that are making a mark in the industry with their innovative designs and commitment to quality. With the demand for high-quality melting furnaces on the rise, these factories are playing a crucial role in meeting the needs of the metallurgical industry and driving innovation in the field of metal processing.In conclusion, the rotary melting furnace industry is witnessing a surge in demand for high-quality equipment, and the factories mentioned above are at the forefront of meeting these needs. Their dedication to quality, innovation, and customer satisfaction is setting a high standard for the industry, and their products are trusted by companies around the world for their reliability and performance. As the industry continues to evolve, these factories are expected to play a crucial role in driving progress and shaping the future of the rotary melting furnace industry.

Top 5 Efficient Aluminium Casting Furnaces for Industrial Use

Title: Cutting-Edge Aluminium Casting Furnace Revolutionizes Manufacturing ProcessesIntroduction:In a groundbreaking development, a leading manufacturing company has unveiled its latest innovation in the realm of aluminium casting furnaces. By removing the brand name, we can shed light on the remarkable technology that promises to transform the industry. This revolutionary furnace incorporates cutting-edge features that optimize efficiency, precision, and sustainability within the aluminum casting process, progressively elevating the standards of manufacturing across sectors worldwide.Unveiling an Innovation:With a deep understanding of the metallurgical processes involved in aluminium casting, the company has introduced an advanced furnace design that pushes the boundaries of conventional methodologies. The newly developed furnace redefines speed, accuracy, and energy efficiency, creating a paradigm shift in the industry.Enhanced Efficiency:The updated aluminium casting furnace utilizes advanced software algorithms to regulate temperature, ensuring optimal melting and casting conditions. This precise temperature control not only reduces energy consumption but also results in faster heating and cooling cycles, significantly increasing overall productivity.Furthermore, the improved furnace promotes seamless metal flow during casting operations, minimizing the occurrence of defects and rework. By enhancing efficiency, the new design allows manufacturers to increase their output while reducing costs, ultimately resulting in higher profit margins.Unmatched Precision:To further elevate the quality of aluminium castings, the redesigned furnace incorporates state-of-the-art monitoring and control systems. These systems leverage advanced sensors to provide real-time data on critical parameters such as temperature, pressure, and metal composition. By maintaining tighter control over these factors, manufacturers can achieve precise and consistent casting results, eliminating product variations.The incorporation of predictive analytics allows operators to identify potential issues before they arise, reducing downtime and optimizing production schedules. The cutting-edge technology employed in this aluminium casting furnace enables manufacturers to deliver high-quality products that meet the stringent specifications demanded by modern industries.Sustainability at the Core:Recognizing the importance of sustainable manufacturing practices, the company has prioritized eco-friendliness throughout the design, development, and operation of the redesigned furnace. By virtue of its improved energy efficiency and reduced waste generation, the new furnace significantly lowers the carbon footprint associated with aluminum casting.Furthermore, the furnace incorporates advanced filtration systems that ensure the capture and removal of harmful emissions, reducing environmental impact. By investing in this technologically advanced equipment, manufacturers can align themselves with global sustainability goals, contributing to a greener and more sustainable future.Market Impact and Future Prospects:The introduction of this game-changing aluminium casting furnace is expected to disrupt the industry and fuel an era of innovation and growth. Manufacturers across sectors, including automotive, aerospace, and construction, are set to benefit from the enhanced efficiency, precision, and sustainability that this revolutionary technology offers.As the demand for superior quality aluminum products continues to rise, companies that embrace this advanced furnace technology will gain a competitive edge over their peers. The improved efficiency and production capabilities will accelerate the delivery of high-quality products, meeting market demands effectively.Looking ahead, the innovative design of this aluminium casting furnace sets the stage for further advancements in the field. The incorporation of artificial intelligence, automation, and robotics holds immense potential to streamline operations and redefine manufacturing standards in the years to come.Conclusion:Undeniably, the introduction of this advanced aluminium casting furnace represents a significant milestone for manufacturers aiming to enhance their productivity, precision, and sustainability. By removing the brand name, we have highlighted the impressive features and benefits that this groundbreaking technology brings to the industry. This furnace showcases the relentless pursuit of excellence and the commitment to innovation that drives the manufacturing sector forward.

Top Electric Melting Furnace Manufacturers and Suppliers in the Market

The Best Melting Furnace Electric Factory is a leading manufacturer and supplier of electric melting furnaces for industrial applications. With years of experience in the industry, the company has earned a reputation for providing high-quality products that are designed to meet the needs of their clients.The company offers a wide range of electric melting furnaces that are perfect for use in various industries such as metalworking, foundries, and jewelry making. Some of the popular products manufactured by the company include electric melting furnaces, induction melting furnaces, and die-casting machines.The electric melting furnaces offered by the company are designed to melt a wide range of metals including gold, silver, aluminum, brass, and copper. These furnaces are made from high-quality materials that ensure they are durable and long-lasting. They also feature state-of-the-art technology that ensures they operate efficiently and effectively.One of the key features of the electric melting furnaces manufactured by the Best Melting Furnace Electric Factory is their versatility. These furnaces are designed to handle a wide range of metal melting applications, making them ideal for use in a variety of industries. They are also designed to be easy to operate and maintain, helping to ensure that clients can get the most out of their investment.In addition to electric melting furnaces, the company also offers induction melting furnaces. These furnaces are designed to operate using electromagnetic induction, making them highly efficient and effective. They are also designed to be compact, making them ideal for use in small spaces.The induction melting furnaces offered by the Best Melting Furnace Electric Factory are made from high-quality materials that ensure they are durable and long-lasting. They also feature advanced technology that helps to ensure they operate efficiently. They are also designed to be easy to operate and maintain, making them an ideal choice for businesses looking to improve their operational efficiency.Another popular product offered by the company is die-casting machines. These machines are designed to produce high-quality metal parts quickly and efficiently. They are ideal for use in the automotive, aerospace, and manufacturing industries.The die-casting machines manufactured by the Best Melting Furnace Electric Factory are made from high-quality materials that ensure they are durable and long-lasting. They also feature advanced technology that helps to ensure they operate efficiently. They are also designed to be easy to operate and maintain, making them an excellent choice for businesses looking to improve their production processes.Overall, the Best Melting Furnace Electric Factory is a reliable and trusted supplier of electric melting furnaces, induction melting furnaces, and die-casting machines. With years of experience in the industry, the company has earned a reputation for providing high-quality products that meet the needs of their clients. If you are looking for a reliable and efficient melting furnace supplier, then the Best Melting Furnace Electric Factory is the perfect choice for your business.

Top Copper Scrap Melting Furnace Manufacturers Revealed

Title: Revolutionary Copper Scrap Melting Furnace Factories Pave the Way for Superior Recycling ProcessesIntroduction:In recent years, the importance of environmentally friendly practices has gained significant momentum across industries. Emphasizing sustainable solutions, copper recycling has emerged as a crucial aspect of waste management. As demand for copper continues to rise, traditional melting methods have struggled to cope with the increasing volume of scrap being generated. However, the rise of cutting-edge copper scrap melting furnace factories has revolutionized the industry, supporting efficient and cost-effective recycling processes.The Need for Advanced Copper Scrap Melting Furnace Factories:Copper, hailed for its exceptional thermal and electrical conductivity, is a crucial component in various industries. From electrical wiring to electronics, plumbing, and renewable energy systems, its versatility is unmatched. Consequently, the demand for copper has surged, creating a need for innovative recycling methods to meet sustainability goals.Conventional copper melting techniques typically involve labor-intensive processes that are often time-consuming and inefficient. These methods struggle to tackle large volumes of scrap, resulting in significant energy wastage and increased carbon emissions. The need for advanced copper scrap melting furnace factories has become increasingly evident to address these challenges.Meet the Pioneers in Copper Scrap Melting Furnace Manufacturing:1. Company A:With a commitment to maximizing the efficiency of copper recycling processes, Company A has established itself as a pioneering manufacturer of advanced melting furnaces. Their cutting-edge technology ensures optimal resource management and reduced energy consumption, making their products a game-changer in the industry. By integrating state-of-the-art features, Company A's furnaces streamline the recycling process, resulting in higher productivity and lower environmental impact.2. Company B:Recognized for their innovative approach, Company B is revolutionizing copper scrap melting furnace manufacturing. Their industry-leading, high-capacity furnaces have gained acclaim for their ability to process large volumes of copper scrap efficiently. These furnaces employ advanced technologies that optimize energy consumption, reducing both operating costs and environmental footprints. With Company B's melting furnaces, recycling centers can significantly increase productivity while minimizing waste.3. Company C:Committed to sustainable practices, Company C has emerged as a prominent manufacturer of copper scrap melting furnaces. Their focus on enhancing energy efficiency has led to the development of furnaces that offer precise temperature control, reducing energy waste during the melting process. Additionally, their furnaces incorporate state-of-the-art filtration systems that capture and neutralize harmful fumes, further contributing to a healthier environment.The Impact of Advanced Copper Scrap Melting Furnace Factories:The introduction of these state-of-the-art melting furnaces has revolutionized the copper recycling industry, offering a range of benefits that positively impact both the economy and the environment.1. Enhanced Efficiency: Advanced features like precise temperature control, induction heating technology, and optimized energy consumption have significantly improved the efficiency of copper scrap melting. This leads to greater productivity, reduced processing time, and cost savings for recycling centers.2. Environmental Considerations: With careful attention to reducing energy consumption and preventing harmful emissions, the advanced melting furnaces help recycling centers meet regulatory standards. By minimizing their carbon footprint, these facilities contribute to a cleaner and healthier environment.3. Resource Conservation: Copper scrap melting furnace factories play a vital role in conserving finite resources by efficiently recycling copper. The increased capacity and improved melting technology ensure maximum utilization of available scrap, thereby reducing the need for new copper production.Conclusion:The rise of advanced copper scrap melting furnace factories has transformed the copper recycling industry. These revolutionary manufacturers, such as Company A, Company B, and Company C, have harnessed cutting-edge technologies to optimize efficiency and minimize environmental impact. Their commitment to sustainability and resource conservation has paved the way for efficient copper recycling, meeting the ever-increasing demand while reducing the strain on natural resources. With such progress, the industry is on track to achieve its sustainability goals, contributing to a greener and more sustainable future.

High-Quality Electric Melting Furnace Factory - Find the Best Options Online

Best Melting Furnace Electric Factory, one of the leading manufacturers of melting furnaces, has been making headlines in the industry with their state-of-the-art technology and top-notch products. The company has been revolutionizing the melting furnace industry with its innovative designs and high-quality materials, making them the go-to choice for businesses around the world.Established in 1998, Best Melting Furnace Electric Factory has been dedicated to providing the best melting furnace solutions for its customers. With years of experience and expertise in the industry, the company has earned a stellar reputation for its reliability and commitment to quality. Their melting furnaces are known for their efficiency, durability, and precision, making them a popular choice for a wide range of applications.The company's commitment to innovation and excellence has led to the development of cutting-edge technology that sets them apart from their competitors. They continue to invest in research and development to stay at the forefront of the industry and provide their customers with the most advanced and efficient melting furnace solutions available.One of the key factors that sets Best Melting Furnace Electric Factory apart from other manufacturers is their dedication to customer satisfaction. They place a strong emphasis on understanding their customers' needs and providing personalized solutions that meet their specific requirements. This customer-centric approach has earned them a loyal and satisfied customer base, further solidifying their position as a leader in the industry.In addition to their exceptional products, the company also prides itself on its superior customer service and support. With a team of highly skilled and knowledgeable professionals, they are able to offer comprehensive assistance to their customers, from the initial consultation to after-sales support. Their commitment to providing a seamless and hassle-free experience for their customers has set them apart as a reliable and trustworthy partner for businesses in need of melting furnace solutions.Best Melting Furnace Electric Factory has also been proactive in implementing eco-friendly and sustainable practices in their manufacturing processes. They are committed to reducing their environmental impact and have taken significant steps to minimize their carbon footprint. Their dedication to sustainability aligns with the growing global focus on environmentally responsible practices, making them an attractive choice for customers looking to align with green initiatives.Furthermore, the company has expanded its reach to serve a global customer base, with a strong presence in various markets around the world. Their products are used in a wide range of industries, including metalworking, automotive, aerospace, and more. This global presence has further solidified their position as a trusted and reliable provider of melting furnace solutions on a global scale.Looking ahead, Best Melting Furnace Electric Factory is poised for continued growth and success in the industry. With their commitment to innovation, quality, and customer satisfaction, they are well-positioned to maintain their leadership position and continue to set new standards for melting furnace technology.In conclusion, Best Melting Furnace Electric Factory has earned its reputation as a leading manufacturer of melting furnaces with its commitment to innovation, quality, and customer satisfaction. With a strong focus on cutting-edge technology, superior customer service, and sustainable practices, the company has established itself as a reliable and trusted partner for businesses across the globe. As they continue to expand their reach and push the boundaries of melting furnace technology, they are poised to maintain their position as an industry leader for years to come.

Leading Furnace Manufacturers Providing Superior Melting Solutions

Superbmelt Furnace Manufacturers, a leading innovator in the field of advanced metal melting and casting solutions, has emerged as a prominent player in the industry. With a commitment to excellence, Superbmelt Furnace Manufacturers has revolutionized the manufacturing process, providing superior quality and reliability to its clients. By utilizing cutting-edge technology and a focus on customer satisfaction, the company has cemented its position as a trusted partner for businesses across various sectors.At Superbmelt Furnace Manufacturers, the pursuit of perfection is ingrained in every aspect of the company's operations. They specialize in the design, development, and production of a wide range of melting furnaces that cater to the diverse needs of their clients. These furnaces are equipped with advanced features, including precise temperature controls, energy efficiency, and ease of use. Whether it is melting gold, silver, platinum, or other precious metals, Superbmelt Furnace Manufacturers offers reliable, efficient, and safe solutions.One of the most prominent products offered by Superbmelt Furnace Manufacturers is their electric gold melting furnace. Designed to meet the demands of the jewelry and mining industries, this furnace utilizes electric heating elements to ensure optimal melting temperatures for gold. The advanced control system allows for precise temperature settings, ensuring the integrity of the gold during the melting process. Additionally, the electric gold melting furnace boasts an energy-efficient design, reducing operational costs for businesses.Superbmelt Furnace Manufacturers also caters to the needs of the recycling industry with their induction metal melting furnace. This furnace utilizes induction heating to rapidly melt various metals, including copper, aluminum, and steel. The induction technology offers numerous advantages, such as uniform heating, improved metallurgical control, and reduced energy consumption. With its ability to efficiently melt and recycle scrap metal, the induction metal melting furnace helps businesses save costs and reduce environmental impact.Apart from melting furnaces, Superbmelt Furnace Manufacturers also produces a range of casting machines that enable the creation of intricate metal objects with precision. Their vacuum casting machine, for instance, utilizes vacuum-assisted casting technology to produce high-quality castings free from porosity and defects. This process ensures the creation of flawless metal parts, meeting the stringent quality requirements of industries such as aerospace, automotive, and jewelry manufacturing.Superbmelt Furnace Manufacturers not only focuses on delivering exceptional products but also provides comprehensive after-sales service and technical support to their clients. Their team of experienced technicians offers on-site installation, training, and maintenance services, ensuring that customers can make the most of their investment. Additionally, the company maintains a readily available stock of spare parts, guaranteeing minimal downtime in case of any equipment malfunction.With a global reach and an established reputation, Superbmelt Furnace Manufacturers has successfully served customers from a wide range of industries worldwide. Their commitment to innovation, reliability, and customer satisfaction has made them a preferred choice for businesses seeking advanced metal melting and casting solutions. As the industry continues to evolve, Superbmelt Furnace Manufacturers is well-positioned to push the boundaries of what is possible, empowering businesses with state-of-the-art technologies for their metal melting and casting needs.In conclusion, Superbmelt Furnace Manufacturers has firmly established itself as a leading player in the field of advanced metal melting and casting solutions. With their cutting-edge technologies, commitment to excellence, and comprehensive customer support, the company continues to drive innovation and set new standards in the industry. As businesses strive for efficiency and reliability in their operational processes, Superbmelt Furnace Manufacturers stands ready to provide world-class melting and casting solutions to meet their evolving needs.

Top Induction Melting Furnace for Brass - A Comprehensive Guide

The use of brass in various industries such as automotive, plumbing, and manufacturing has made its demand soar in recent years. To meet this demand, companies are constantly seeking innovative ways to efficiently produce high-quality brass products. One such company leading the way in brass production is Best Brass Induction Melting Furnace.Best Brass Induction Melting Furnace is a leading manufacturer of cutting-edge induction melting furnaces that are designed to cater to the specific needs of brass production. The company has been at the forefront of technological advancements in the field of metal melting and has established a strong reputation for delivering top-notch equipment to its clients.The induction melting furnaces produced by Best Brass Induction Melting Furnace are renowned for their efficiency, reliability, and precision. These furnaces are capable of melting a wide range of metals, including brass, copper, aluminum, and gold, with unparalleled accuracy and speed. The advanced induction heating technology used in these furnaces ensures that the metal is melted uniformly and without any impurities, resulting in high-quality brass products.In addition to its cutting-edge technology, Best Brass Induction Melting Furnace takes pride in its commitment to sustainability and environmental responsibility. The company has incorporated energy-efficient features in its induction melting furnaces, making them more eco-friendly and cost-effective to operate. This aligns with the global push towards environmentally conscious manufacturing practices and has made Best Brass Induction Melting Furnace an attractive choice for businesses looking to reduce their carbon footprint.Furthermore, Best Brass Induction Melting Furnace offers a comprehensive range of services to support its clients in maximizing the performance of their induction melting furnaces. From installation and commissioning to maintenance and technical support, the company provides end-to-end solutions to ensure the seamless operation of its equipment.The success of Best Brass Induction Melting Furnace can be attributed to its unwavering dedication to innovation and customer satisfaction. The company invests heavily in research and development to stay ahead of the curve and continuously improve its products to meet the evolving needs of the industry. Moreover, Best Brass Induction Melting Furnace values its relationships with clients and strives to provide personalized solutions that address their specific requirements.As the demand for brass continues to rise, the role of Best Brass Induction Melting Furnace in the industry becomes increasingly vital. The company’s induction melting furnaces are well-equipped to meet the challenges of modern brass production and are poised to play a crucial role in shaping the future of the industry.In conclusion, Best Brass Induction Melting Furnace’s commitment to technological innovation, environmental sustainability, and customer-centric approach has solidified its position as a leader in the field of metal melting equipment. With its advanced induction melting furnaces and unwavering dedication to excellence, the company is well-positioned to meet the growing demand for high-quality brass products and drive the industry forward.

China's Leading Suppliers of Melting Furnace Electric Equipment

China Melting Furnace Electric Suppliers Leading the Way in Energy-Saving Technology for the Metallurgical IndustryChina Melting Furnace Electric Suppliers (CMFES) is one of the leading providers of energy-efficient electric melting furnaces in China. The company has been serving the metallurgical industry for over a decade and has gained an excellent reputation for the quality and reliability of its products. CMFES is committed to developing innovative solutions that help its customers increase their productivity, reduce their energy consumption, and minimize their environmental impact.CMFES offers a wide range of electric melting furnaces that are designed to meet the specific needs of different types of metal processing applications. The company's product portfolio includes induction furnaces, arc furnaces, resistance furnaces, and other specialty furnaces. These furnaces are used for melting and casting various types of metals, such as steel, iron, copper, aluminum, and alloys. One of the key advantages of CMFES electric melting furnaces is their energy efficiency. The company uses advanced technologies to optimize the performance of its furnaces, such as high frequency induction heating, regenerative combustion, and automatic temperature control. These features help to reduce the energy consumption of the furnaces by up to 30%, compared to traditional melting methods. This not only saves energy but also lowers the operating costs of the customers, enabling them to stay competitive in the global market.Moreover, CMFES has a strong focus on environmental sustainability and has developed several solutions to address the challenges of reducing emissions and waste. For instance, the company's regenerative combustion technology enables the furnaces to recover waste heat and reuse it for the next melting cycle. This not only saves energy but also promotes cleaner air quality by reducing the amount of pollutants emitted into the atmosphere. CMFES also offers recycling solutions for the metal scraps generated from the melting process, ensuring that the materials are reused and not wasted.In addition to offering high-quality products, CMFES provides excellent customer support and after-sales service. The company has a team of experienced engineers and technicians who work closely with the customers to understand their specific requirements and provide customized solutions. CMFES also offers training and maintenance services, ensuring that the furnaces operate efficiently and safely over their lifespan.CMFES is committed to continuous innovation and has invested significant resources in R&D to develop new technologies and improve its existing products. The company collaborates with leading universities and research institutions to stay up-to-date with the latest trends and developments in the metallurgical industry. CMFES has a strong intellectual property portfolio and has obtained several patents for its inventions.Looking ahead, CMFES sees enormous growth potential in the global metallurgical market, especially in emerging economies where demand for metals is increasing rapidly. The company plans to expand its business globally and strengthen its partnerships with key customers and distributors. CMFES aims to become a leading player in the international melting furnace market, offering cutting-edge solutions that help customers achieve their business goals while contributing to a sustainable future for the planet.In conclusion, China Melting Furnace Electric Suppliers is an innovative company that is leading the way in energy-saving technology for the metallurgical industry. The company's commitment to sustainability and customer satisfaction has earned it a loyal following among its customers and a reputation as a trusted provider of high-quality melting furnaces. As the world's demand for metals continues to grow, CMFES is well-positioned to capitalize on this trend and drive sustainable growth for the benefit of all stakeholders.

High-Quality Metal Melting Furnaces Available for Purchase

Metal Melting Furnace For Sale: Highly Efficient and Reliable Solution for Metal Smelting Needs{Insert company name} is happy to introduce its latest offering – the metal melting furnace for sale. Our company has always been at the forefront of providing the best and most innovative solutions to meet the metal smelting and refining needs of our clients. With this new product, we aim to continue our tradition of excellence and provide a highly efficient and reliable option for those who are in search of the best metal melting furnace.Our metal melting furnace is a game changer in the industry, as it offers many benefits that traditional furnaces lack. Here are some of the advantages that our clients can expect from our product:Ease of UseOne of the most significant benefits that our metal melting furnace for sale offers is ease of use. The product is straightforward to operate, thanks to its intuitive design. Even those who are not experts in metal smelting and casting will find our product easy to use. Additionally, it is highly portable and can be used in various settings, making it a versatile solution for those who need to carry out metal melting and refining operations on-site.High EfficiencyAnother significant benefit of our metal melting furnace is its high efficiency. The furnace is designed to use a minimal amount of energy to melt metals quickly. Thus, it reduces the amount of fuel consumption, which translates into reduced energy costs. Additionally, it has a high melting rate, which allows for the quick and efficient melting of large metal pieces.Excellent PerformanceOur metal melting furnace provides excellent performance, making it the preferred choice for many of our clients. It is designed to operate at high temperatures, up to 2600 °F, allowing for the melting of a wide range of metals. The furnace is also equipped with advanced features, such as a digital temperature control system, which ensures accurate temperature control during melting and casting operations.DurabilityDurability is an essential factor in the selection of a metal melting furnace for sale. Our product is built to last. It is made of high-quality materials that can withstand high temperatures and harsh working conditions. The product is also designed with safety features such as emergency shut-off valves that ensure safe operation of the furnace.Cost-Effective SolutionOur metal melting furnace is not only efficient but also cost-effective. Our clients can benefit significantly from the reduced energy costs as a result of using our product. Moreover, its high melting rate results in reduced processing time, which translates to lower labor costs.Easy MaintenanceFinally, our metal melting furnace is easy to maintain. Regular maintenance is essential to ensure optimal performance and durability of the product. Our product is designed with a minimal number of parts and simple maintenance procedures. Thus, it can be easily serviced, and spare parts are readily available.In conclusion, {insert company name} offers a highly efficient and reliable metal melting furnace for sale. The product is designed to meet the metal smelting and casting needs of various industries, including automotive, aerospace, and jewelry making. We are confident that our clients will be satisfied with the performance, ease of use, durability, and affordability of our product. Contact us today to learn more about our metal melting furnace and how it can benefit your operations.