China Brass Induction Melting Furnace Manufacturers: Key Insights

By:Admin

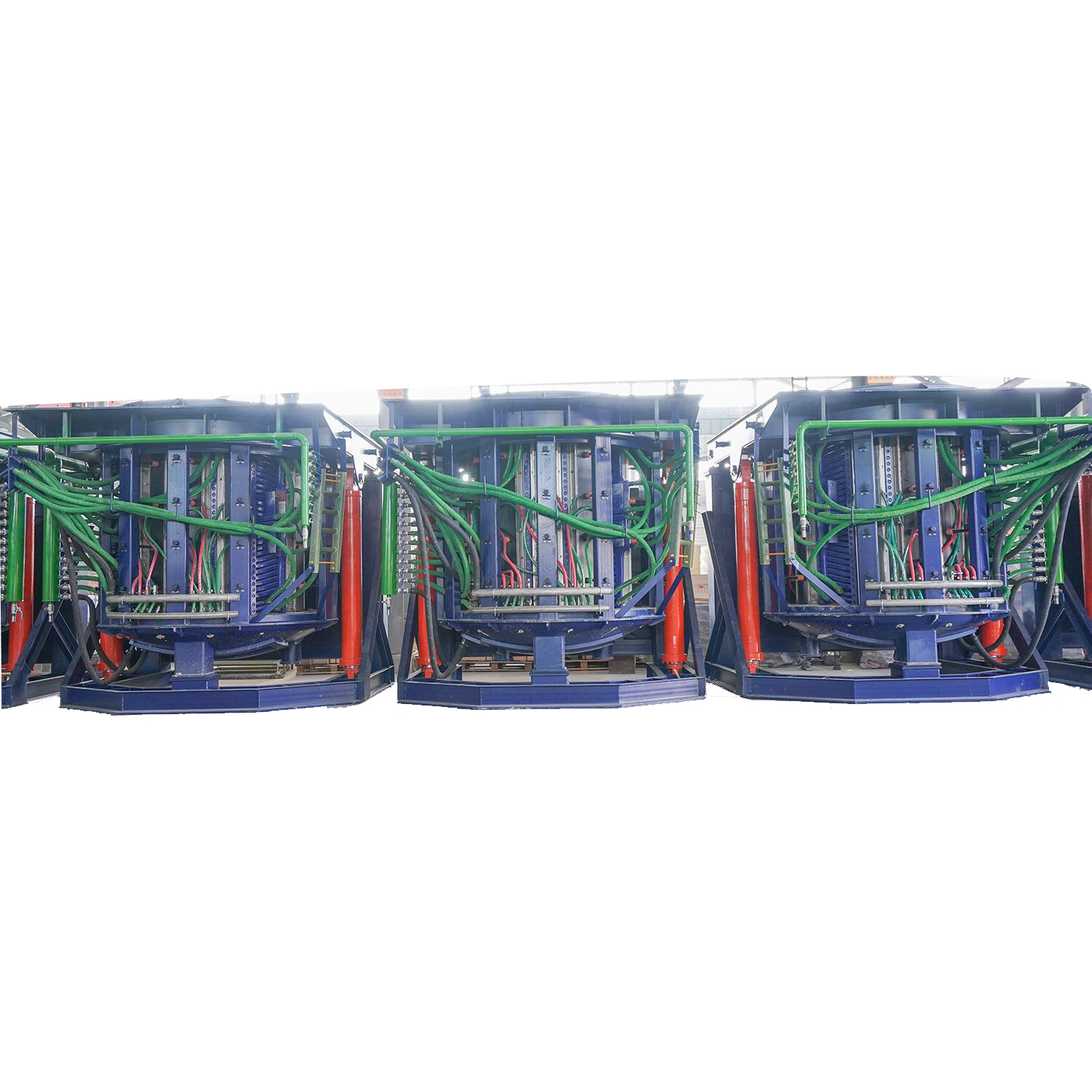

With the increasing demand for brass induction melting furnaces in various industries, China's leading brass induction melting furnace factories have recently expanded their production capacity. These factories, known for their expertise and high-quality products, aim to meet the growing market needs while maintaining their commitment to excellence.

Brass induction melting furnaces are widely used in industries such as metal casting, automotive, aerospace, and jewelry manufacturing. These furnaces use the induction heating method to melt and refine brass, creating high-quality, precision-crafted products. Given the importance of these furnaces in numerous manufacturing sectors, the growing demand is not surprising.

One of the notable factories, which prefers to remain anonymous, has taken a significant step to expand its production capacity. This decision was made in response to the rising market demand for brass induction melting furnaces. The factory, equipped with state-of-the-art technology and a dedicated team, has been delivering exceptional products to customers for many years.

The factory's new production facility boasts advanced machinery and equipment, allowing for increased output without compromising on quality. The expansion is expected to reduce lead times, ensuring customers receive their orders promptly. With a larger workforce, the factory will be able to handle the increased production volume efficiently.

In addition to expanding the production capacity, the factory has also invested in research and development to enhance the performance and efficiency of their brass induction melting furnaces. By leveraging the latest technological advancements and industry insights, they aim to provide customers with even better products in the future.

One of the key advantages of choosing brass induction melting furnaces from China is the competitive pricing. The country's manufacturing capabilities and cost-effective production processes enable factories to offer high-quality products at a lower cost compared to their international counterparts. This has made China a preferred destination for businesses seeking reliable and affordable brass induction melting furnaces.

Furthermore, China has established itself as a hub for technological innovation. The factories invest heavily in research and development, often collaborating with universities and research institutions to stay at the forefront of technological advancements. This continuous pursuit of innovation allows them to develop cutting-edge products that meet the evolving needs of various industries.

The recent expansion of China's brass induction melting furnace factories is expected to have a positive impact on the overall market. With increased production capacity, shorter lead times, and continued emphasis on quality, these factories are well-positioned to cater to the growing demand for brass induction melting furnaces.

Customers in need of brass induction melting furnaces can rely on these factories for their expertise, commitment to excellence, and unmatched product quality. As they continue to explore new technological possibilities and deliver innovative solutions, the factories are likely to shape the future of brass induction melting furnace manufacturing.

In conclusion, the expansion of China's brass induction melting furnace factories demonstrates their dedication to meeting the increasing market demand. With advanced production facilities, research and development initiatives, and a commitment to excellence, these factories are set to continue providing high-quality brass induction melting furnaces to industries worldwide.

Company News & Blog

A Guide to the Latest Technology in Induction Heating Furnaces

Introducing the Future of Industrial Heating: Induction Heating FurnaceIn the ever-evolving industrial landscape, the need for efficient and sustainable heating solutions has become paramount. Conventional methods of heating, such as gas burners and electric furnaces, have their limitations in terms of energy consumption and overall productivity. However, recent advancements in technology have given rise to a revolutionary heating technique known as induction heating. With its many advantages over traditional methods, induction heating furnaces are poised to transform the industrial sector.Induction heating is a process wherein an electrically conductive material is heated by electromagnetic induction. This results in faster heating times, increased energy efficiency, and precise temperature control. Additionally, induction heating is a clean and eco-friendly method as it produces no open flames or noxious emissions. It is these characteristics that have led to the development and widespread adoption of induction heating furnaces across various industries.One leading player in the field of induction heating furnaces is {} (brand name removed). With a rich history spanning over three decades, {} has established itself as a pioneer in the design and manufacturing of these cutting-edge technologies. The company's commitment to continuous innovation and customer-centric approach has propelled them to the forefront of the industry.With the introduction of their latest induction heating furnace, {} aims to redefine industrial heating standards. This state-of-the-art furnace boasts a range of features that not only enhance productivity but also contribute to a cleaner and more sustainable environment. The furnace's advanced control system ensures precise temperature management, resulting in minimized heating times and increased efficiency. This efficiency translates to significant cost savings for businesses, allowing them to streamline their operations and stay competitive in the market.Furthermore, {}'s induction heating furnace is designed with an emphasis on durability and reliability. The use of high-quality materials and innovative engineering techniques ensures that the furnace performs consistently under demanding conditions. Its robust construction also minimizes downtime, reducing maintenance costs and improving overall productivity.The induction heating furnace offered by {} is highly adaptable, making it suitable for a wide range of applications across various industries. From metal fabrication and forging to heat treatment and melting, this furnace can cater to diverse heating requirements. Its versatility and flexibility set it apart from traditional heating methods, as it offers unparalleled control and precision in heating processes.In addition to its technical excellence, {} places a strong emphasis on customer support and service. The company's team of dedicated professionals works closely with clients to understand their specific needs and provide tailored solutions. This customer-centric approach has earned them a reputation for reliability and trustworthiness in the industry.With rapidly increasing demand for sustainable and energy-efficient solutions, the future of industrial heating belongs to induction heating furnaces. As they continue to gain traction in the market, it is companies like {} that are leading the charge, revolutionizing the way businesses heat their operations. By combining technological innovation, superior performance, and exceptional customer service, {} is shaping the future of industrial heating, one furnace at a time.As industries strive for increased efficiency, reduced costs, and improved environmental impact, induction heating furnaces emerge as the ideal choice. It is through the relentless pursuit of excellence by companies like {} that the industrial sector can witness transformative advancements.

Top Aluminum Smelting Equipment for Efficient and Sustainable Production

Aluminum Smelting Equipment Company Unveils New State-of-the-Art Metal Smelting ProcessAluminum Smelting Equipment Company, a leading provider of aluminum smelting equipment and services, has recently introduced a new state-of-the-art metal smelting process that promises to revolutionize the industry.The company has long been committed to providing its customers with innovative and cost-effective solutions for aluminum smelting. Its new smelting process builds on years of experience and expertise in the field, incorporating the latest technological advancements to deliver unparalleled efficiency and quality in the production of aluminum.The new process utilizes a combination of advanced smelting techniques and cutting-edge equipment to produce aluminum in a highly efficient and eco-friendly manner. At the core of the process is a proprietary smelting technology that enables the company to smelt aluminum at a significantly lower temperature than traditional methods, resulting in a dramatic reduction in energy consumption and greenhouse gas emissions.The technology also allows for the recovery of valuable by-products, such as aluminum oxide and carbon, which can be reused and recycled. This not only reduces waste and improves sustainability, but also helps to keep costs down for the company’s customers.Along with the advanced smelting technology, Aluminum Smelting Equipment Company has also invested heavily in the development of state-of-the-art equipment to support the new process. This includes furnaces, casting machines, and other specialized equipment that have been specifically designed to work seamlessly with the company’s proprietary smelting technology.Combined, the new smelting process and equipment deliver a range of benefits for the company’s customers. For one, it allows for faster, more efficient production of high-quality aluminum, without sacrificing sustainability or safety. This is especially important in an industry that is becoming increasingly competitive, and where margins are often tight.The new process also reduces costs, both in terms of energy consumption and material waste, while also providing customers with access to valuable by-products that can be reused or sold. For companies that are looking to improve their bottom line and enhance their environmental credentials, this is a game-changer.In addition to the technical innovations, Aluminum Smelting Equipment Company has also invested in its people to ensure that they have the skills and expertise needed to operate the new process and equipment effectively. The company’s workforce includes highly skilled engineers, technicians, and other professionals who work closely with customers to design and implement customized solutions that meet their specific needs.Aluminum Smelting Equipment Company is not only committed to delivering exceptional products and services, but also to making a positive impact on the communities in which it operates. The company operates with a strong sense of environmental and social responsibility, and actively works to minimize its footprint and improve the lives of those around it.Overall, the introduction of the new smelting process represents a significant milestone for Aluminum Smelting Equipment Company. With its advanced technology, state-of-the-art equipment, and commitment to sustainability and social responsibility, the company is well-positioned to continue driving innovation in the aluminum industry and delivering value to its customers for years to come.

Top Electric Melting Furnace Manufacturers and Suppliers in the Market

The Best Melting Furnace Electric Factory is a leading manufacturer and supplier of electric melting furnaces for industrial applications. With years of experience in the industry, the company has earned a reputation for providing high-quality products that are designed to meet the needs of their clients.The company offers a wide range of electric melting furnaces that are perfect for use in various industries such as metalworking, foundries, and jewelry making. Some of the popular products manufactured by the company include electric melting furnaces, induction melting furnaces, and die-casting machines.The electric melting furnaces offered by the company are designed to melt a wide range of metals including gold, silver, aluminum, brass, and copper. These furnaces are made from high-quality materials that ensure they are durable and long-lasting. They also feature state-of-the-art technology that ensures they operate efficiently and effectively.One of the key features of the electric melting furnaces manufactured by the Best Melting Furnace Electric Factory is their versatility. These furnaces are designed to handle a wide range of metal melting applications, making them ideal for use in a variety of industries. They are also designed to be easy to operate and maintain, helping to ensure that clients can get the most out of their investment.In addition to electric melting furnaces, the company also offers induction melting furnaces. These furnaces are designed to operate using electromagnetic induction, making them highly efficient and effective. They are also designed to be compact, making them ideal for use in small spaces.The induction melting furnaces offered by the Best Melting Furnace Electric Factory are made from high-quality materials that ensure they are durable and long-lasting. They also feature advanced technology that helps to ensure they operate efficiently. They are also designed to be easy to operate and maintain, making them an ideal choice for businesses looking to improve their operational efficiency.Another popular product offered by the company is die-casting machines. These machines are designed to produce high-quality metal parts quickly and efficiently. They are ideal for use in the automotive, aerospace, and manufacturing industries.The die-casting machines manufactured by the Best Melting Furnace Electric Factory are made from high-quality materials that ensure they are durable and long-lasting. They also feature advanced technology that helps to ensure they operate efficiently. They are also designed to be easy to operate and maintain, making them an excellent choice for businesses looking to improve their production processes.Overall, the Best Melting Furnace Electric Factory is a reliable and trusted supplier of electric melting furnaces, induction melting furnaces, and die-casting machines. With years of experience in the industry, the company has earned a reputation for providing high-quality products that meet the needs of their clients. If you are looking for a reliable and efficient melting furnace supplier, then the Best Melting Furnace Electric Factory is the perfect choice for your business.

Discover the Secrets of Steel Melting Forges for Efficient Metal Transformation

[News Content]Steel Melting Forge Facility Increases Production Capacity, Boosting Company's Competitive Advantage[City, Date] – In an effort to expand their production capabilities and enhance overall efficiency, [Company Name] has successfully commissioned a new steel melting forge facility at their manufacturing plant. With this strategic investment, the company aims to meet the growing demand for high-quality steel products and strengthen its position in the market.The state-of-the-art steel melting forge, equipped with cutting-edge technology, boasts an impressive range of features that streamline the production process. It offers precision control over the melting process, ensuring superior material quality and consistency. The facility is also designed to minimize energy consumption, leading to both environmental and cost-saving benefits.By investing in the new steel melting forge, [Company Name] is geared towards significantly increasing its production capacity. The facility's advanced automation systems allow for continuous and uninterrupted production, reducing downtime and optimizing output. This will enable the company to deliver orders to customers more efficiently and promptly, thereby improving customer satisfaction and maintaining a leading position in the industry.[Company Name], a renowned player in the steel manufacturing industry, has continuously strived to integrate the latest technological advancements into its operations. The introduction of the steel melting forge further reinforces the company's commitment to innovation and growth.With this new addition, [Company Name] aims to cater to a wider range of industries, including automotive, construction, and machinery manufacturing. The facility's ability to melt various grades of steel, such as carbon steel, stainless steel, and alloy steel, ensures that the company can meet diverse customer requirements in terms of material specifications and performance characteristics."Expanding our production capabilities is crucial to meeting the evolving needs of our customers," said [Company Name]'s CEO. "The steel melting forge facility will play a pivotal role in strengthening our market position and increasing our competitiveness."Moreover, the new facility aligns with [Company Name]'s commitment to sustainability and reducing its environmental footprint. By incorporating energy-efficient technologies into the steel melting process, the company aims to minimize carbon emissions and optimize resource utilization. This investment not only benefits the business but also demonstrates [Company Name]'s dedication to being a responsible corporate citizen.To uphold its high standards of quality assurance, [Company Name] has also invested in a comprehensive inspection and testing system within the steel melting forge facility. This system enables continuous monitoring of the molten steel composition, ensuring compliance with stringent quality control standards. By doing so, the company guarantees consistent product quality and reliability, reinforcing customer trust in its offerings.The new steel melting forge facility is expected to generate employment opportunities, benefiting both the local community and the wider economy. Its implementation showcases [Company Name]'s commitment to fostering economic growth through sustained investment and innovation.With the commissioning of the steel melting forge facility, [Company Name] is poised to solidify its position as a market leader in the steel manufacturing sector. The increased production capacity, along with enhanced operational efficiency, will enable the company to address market demands effectively and cater to a diverse customer base, ultimately driving its growth and success.About [Company Name]:[Company Name] is a globally recognized steel manufacturing company, dedicated to delivering high-quality steel products to various industries. With a commitment to innovation, sustainability, and customer satisfaction, [Company Name] remains at the forefront of the steel industry, driving its growth and success.Press Contact:[Name][Designation][Company Name][Phone][Email]

Best Supplier for Induction Furnace Frequencies

Induction furnaces have revolutionized the world of metallurgy and manufacturing, providing a highly efficient and cost-effective alternative to traditional methods of melting and pouring metal. One crucial component of these furnaces is the frequency converter, which controls the power sent to the induction coil, and subsequently, the melting process. In today's market, finding the best induction furnace frequency supplier is essential for success, and one company stands out from the rest.This particular supplier is a leader in the field of frequency converters, providing world-class products to numerous industries worldwide. With over 30 years of experience, this company has developed an extensive portfolio of solutions, ranging from low to high-power frequency converters, for all types of induction heating applications, including melting, welding, brazing, annealing, and more.Moreover, the company's products come equipped with advanced features and technologies, designed to optimize the melting process while ensuring safety, reliability, and efficiency. Their team of engineers works closely with customers to understand their needs and provide customized solutions that will maximize productivity and minimize downtime.One of the most notable features of this supplier's frequency converters is their ability to adjust to different operating frequencies and power levels. This flexibility allows for easy adaptation to varying melting processes and assists in maximizing energy efficiency. Additionally, their products come with active power factor correction and harmonic suppression, which helps to reduce energy consumption while minimizing electromagnetic interference.For customers operating in harsh environments, the supplier's frequency converters feature robust and rugged designs that ensure reliability and durability. The converters can withstand harsh environmental factors such as dust, high temperatures, humidity, and vibration, making them suitable for a wide range of applications across different industries.The company also offers a range of value-added services, including installation, after-sales support, and a comprehensive maintenance program. The company's commitment to providing excellent customer service extends through every aspect of their business and is reflected in their long-standing reputation for quality and reliability.Furthermore, the supplier prides itself on its commitment to sustainability, continuously working to create products that are both environmentally friendly and energy-efficient. Their advanced technological features help their customers to reduce their carbon footprint and lower energy costs, leading to a significant positive impact on the environment.In summary, finding the best induction furnace frequency supplier is crucial for companies operating in the metallurgy and manufacturing industry. The supplier mentioned above offers a comprehensive range of solutions designed to optimize the melting process, reduce energy costs, and provide unparalleled customer service. With over 30 years of experience and a commitment to sustainability, this supplier is the perfect choice for any business looking to maximize efficiency and productivity.

Top 5 Leading Furnace Factories for the Best Brass Casting

Best Brass Casting Furnace Factories Revolutionizing the Metal Casting IndustryIn today's rapidly advancing world, the demand for high-quality metal castings is on the rise. The brass casting industry, in particular, plays a crucial role in numerous sectors, from automotive to aerospace and many more. To meet these ever-growing market demands, several brass casting furnace factories have emerged as key players in revolutionizing the metal casting industry. This article will delve into the importance of these factories and how they are reshaping the future of metal casting.Brass casting furnace factories are dedicated to producing top-notch equipment and revolutionizing the casting process. Their commitment to quality and innovation has propelled them ahead of their competitors, making them leaders in the industry. These factories tirelessly work towards developing robust and efficient furnaces that enhance the overall casting operations.One of the notable brass casting furnace factories is {}. This factory has established itself as a force to be reckoned with, gaining the trust and loyalty of countless clients worldwide. Their extensive experience combined with state-of-the-art technology has enabled them to achieve remarkable success in the industry.This factory emphasizes precision and efficiency in their furnaces, ensuring that every casting operation yields superior results. They strive to understand the specific requirements of their clients and tailor their furnace solutions accordingly. Whether it is a small-scale foundry or a large-scale industrial operation, the factory provides a diverse range of furnaces to suit different casting needs.Moreover, the factory continually invests in research and development to stay at the forefront of technological advancements. By forging strategic partnerships with leading experts and institutions, they actively participate in the development of new casting techniques and materials. This commitment to innovation allows them to offer furnaces that not only meet industry standards but also surpass them, setting new benchmarks for the casting process.Another significant feature of these brass casting furnace factories is their dedication to environmental sustainability. Recognizing the need for responsible manufacturing, these factories employ eco-friendly practices that minimize waste and reduce energy consumption. They strive to develop energy-efficient furnaces that minimize the carbon footprint without compromising on the quality or efficiency of the casting process. This focus on sustainability aligns with the global call for a greener and more sustainable future.Furthermore, these factories prioritize customer satisfaction by offering comprehensive after-sales services. They understand that the relationship with their clients extends beyond the initial purchase. Hence, they provide technical assistance, maintenance support, and spare parts to ensure the smooth functioning of the furnaces. This commitment to excellent customer service has garnered them a loyal customer base and has solidified their reputation as a reliable and trusted partner in the industry.Looking ahead, these brass casting furnace factories continue to push boundaries and drive advancements in the metal casting industry. By utilizing emerging technologies like artificial intelligence and automation, they aim to streamline the casting process further. This not only improves efficiency but also enhances the overall quality of castings, making them more precise and reliable.In conclusion, the emergence of brass casting furnace factories has revolutionized the metal casting industry. Through their commitment to quality, innovation, and sustainability, these factories are reshaping the future of casting. Their technological advancements and dedication to customer satisfaction set them apart and position them as industry leaders. As the demand for high-quality metal castings continues to grow, these factories will undoubtedly remain pivotal in meeting the evolving market needs.

Guide to Induction Melting Metal for Efficient Metal Processing

Title: Induction Melting Technology Revolutionizes Metal Processing - A Game-Changer in Manufacturing IndustriesIntroduction (100 words):In the realm of metal processing, innovative technologies have consistently played a vital role in driving progress and efficiency. One such groundbreaking invention is induction melting technology - an advanced, high-performance method designed to enhance metal melting and refining processes. Developed and perfected by {company name}, this cutting-edge technique is revolutionizing the manufacturing industry. This news article will delve into the intricacies of induction melting, its various applications, and the extensive benefits it offers to businesses across different sectors.Section 1: The Power of Induction Melting for Metal Processing (200 words)Since its introduction, induction melting technology has transformed the way metals are melted and processed. Utilizing electromagnetic induction, this technique employs an alternating current to generate a magnetic field that induces eddy currents within the metal product being melted. These eddy currents, in turn, produce heat due to resistance, leading to the melting of the metal.One of the primary advantages of induction melting is its ability to achieve high melting rates. Compared to traditional melting methods, induction melting proves to be significantly faster and more energy-efficient. This technology also ensures uniform heating, preventing hot spots or inconsistencies in the metal surface, resulting in a higher-quality end product.Section 2: Applications of Induction Melting (250 words)The versatility of induction melting makes it applicable to a broad range of industries. From small-scale foundries and metalworking companies to larger manufacturing plants, this technology has become indispensable across many sectors.In the automotive industry, induction melting has revolutionized the production of critical engine components such as pistons, cylinders, and crankshafts. Through high-precision melting and alloying, this advanced method enhances the durability, strength, and performance of these vital automotive parts.Additionally, the aerospace industry benefits greatly from induction melting technology. From constructing turbine blades to manufacturing aircraft parts, the rapid heating and precise temperature control offered by this technique ensures the production of lightweight, high-strength, and heat-resistant components.Other sectors, such as jewelry manufacturing, electrical equipment manufacturing, and metal recycling, have all turned to induction melting for its accuracy, speed, and cost-efficiency. The process is easily customizable to cater to specific melting requirements, making it an ideal choice for various metallurgical applications.Section 3: {Company Name} - A Pioneer in Induction Melting Technology (200 words){Company Name} has established itself as a frontrunner in the field of induction melting, relentlessly pushing boundaries and setting new standards for metal processing. With years of research and development, the company has perfected their advanced induction melting equipment and machines - removing thermal inefficiencies and enhancing energy utilization.The company's range of induction melting systems offers flexibility, efficiency, and unmatched performance. These systems are designed to melt different types of metals, including steel, iron, aluminum, and precious metals, enabling businesses to harness the full potential of induction melting technology.Moreover, {Company Name} provides comprehensive training and support to ensure seamless integration of the technology into existing manufacturing processes. They have also introduced user-friendly interfaces and automated features to simplify operation and maximize productivity.Conclusion (150 words):Induction melting technology has truly revolutionized metal processing, providing an unparalleled solution for businesses seeking enhanced efficiency and quality in their manufacturing processes. With its ability to achieve uniform heating, precise control, and remarkable energy efficiency, this technology is instrumental in shaping the future of various industries. {Company Name}'s expertise and innovation continue to drive the advancements and adoption of this groundbreaking technology, cementing its role as a pioneer in the field.By harnessing the power of induction melting technology, businesses can optimize their operations, reduce costs, and deliver superior products to meet the ever-growing demands of the modern market. As the manufacturing industry continues to evolve, induction melting stands as a testament to the transformative capabilities of technology in shaping progress and growth.

Leading Furnace Manufacturers Providing Superior Melting Solutions

Superbmelt Furnace Manufacturers, a leading innovator in the field of advanced metal melting and casting solutions, has emerged as a prominent player in the industry. With a commitment to excellence, Superbmelt Furnace Manufacturers has revolutionized the manufacturing process, providing superior quality and reliability to its clients. By utilizing cutting-edge technology and a focus on customer satisfaction, the company has cemented its position as a trusted partner for businesses across various sectors.At Superbmelt Furnace Manufacturers, the pursuit of perfection is ingrained in every aspect of the company's operations. They specialize in the design, development, and production of a wide range of melting furnaces that cater to the diverse needs of their clients. These furnaces are equipped with advanced features, including precise temperature controls, energy efficiency, and ease of use. Whether it is melting gold, silver, platinum, or other precious metals, Superbmelt Furnace Manufacturers offers reliable, efficient, and safe solutions.One of the most prominent products offered by Superbmelt Furnace Manufacturers is their electric gold melting furnace. Designed to meet the demands of the jewelry and mining industries, this furnace utilizes electric heating elements to ensure optimal melting temperatures for gold. The advanced control system allows for precise temperature settings, ensuring the integrity of the gold during the melting process. Additionally, the electric gold melting furnace boasts an energy-efficient design, reducing operational costs for businesses.Superbmelt Furnace Manufacturers also caters to the needs of the recycling industry with their induction metal melting furnace. This furnace utilizes induction heating to rapidly melt various metals, including copper, aluminum, and steel. The induction technology offers numerous advantages, such as uniform heating, improved metallurgical control, and reduced energy consumption. With its ability to efficiently melt and recycle scrap metal, the induction metal melting furnace helps businesses save costs and reduce environmental impact.Apart from melting furnaces, Superbmelt Furnace Manufacturers also produces a range of casting machines that enable the creation of intricate metal objects with precision. Their vacuum casting machine, for instance, utilizes vacuum-assisted casting technology to produce high-quality castings free from porosity and defects. This process ensures the creation of flawless metal parts, meeting the stringent quality requirements of industries such as aerospace, automotive, and jewelry manufacturing.Superbmelt Furnace Manufacturers not only focuses on delivering exceptional products but also provides comprehensive after-sales service and technical support to their clients. Their team of experienced technicians offers on-site installation, training, and maintenance services, ensuring that customers can make the most of their investment. Additionally, the company maintains a readily available stock of spare parts, guaranteeing minimal downtime in case of any equipment malfunction.With a global reach and an established reputation, Superbmelt Furnace Manufacturers has successfully served customers from a wide range of industries worldwide. Their commitment to innovation, reliability, and customer satisfaction has made them a preferred choice for businesses seeking advanced metal melting and casting solutions. As the industry continues to evolve, Superbmelt Furnace Manufacturers is well-positioned to push the boundaries of what is possible, empowering businesses with state-of-the-art technologies for their metal melting and casting needs.In conclusion, Superbmelt Furnace Manufacturers has firmly established itself as a leading player in the field of advanced metal melting and casting solutions. With their cutting-edge technologies, commitment to excellence, and comprehensive customer support, the company continues to drive innovation and set new standards in the industry. As businesses strive for efficiency and reliability in their operational processes, Superbmelt Furnace Manufacturers stands ready to provide world-class melting and casting solutions to meet their evolving needs.

Massive Industrial Smelting Furnaces Boosting Metal Processing Efficiency

Recently, a large smelting furnace (brand name removed) has been introduced by one of the leading companies in the industry. With its advanced technology, this furnace has the potential to revolutionize the smelting process, making it easier, more efficient, and environmentally friendly.The large smelting furnace is capable of melting and refining a variety of metals, including copper, aluminum, zinc, and lead. It is particularly suitable for the production of high-quality metals, which are used in a wide range of applications such as construction, electronics, and automotive manufacturing.The furnace boasts of advanced features that set it apart from traditional furnaces. Its unique design allows for faster heating and cooling times, reducing the overall processing time significantly. Additionally, the furnace's digital controls ensure that the temperature and other parameters are accurately maintained, leading to a more precise and consistent product.Another key benefit of the furnace is its energy efficiency. By using state-of-the-art insulation and heat recovery systems, the furnace can operate at a much lower energy consumption than similar furnaces in the market. This translates to lower production costs, as well as reduced carbon emissions.The company behind the large smelting furnace is a well-established player in the industry, known for its cutting-edge technology and innovative solutions. With over five decades of experience, the company has built a reputation for delivering high-quality products and exceptional customer service.According to the spokesperson of the company, "We are thrilled to introduce the large smelting furnace to the market. This furnace represents a significant advancement in the smelting process, and we believe it will bring substantial benefits to our customers. We are confident that the furnace's advanced features and energy efficiency will help our customers optimize their production processes and reduce costs. We are committed to providing the best possible product and support to our customers."The company has already received several inquiries and orders for the furnace, indicating a strong demand for this innovative technology. Many customers have expressed their excitement about the prospects of using the furnace to improve their production processes and enhance their competitive edge.One of the customers who has already ordered the large smelting furnace is a leading aluminum manufacturer. The company's spokesperson commented, "We are constantly exploring new technologies that can help us improve our production processes and reduce our environmental impact. The large smelting furnace fits perfectly into our vision, and we are excited to incorporate it into our operations. We believe this furnace will allow us to produce higher quality aluminum at a lower cost, while also reducing our carbon footprint."Overall, the large smelting furnace is set to make a significant impact on the metal industry, offering a faster, more precise, and more environmentally-friendly alternative to traditional smelting processes. With a strong demand from customers and the backing of a reputable company, this furnace is poised to become a game-changer in the industry.

Top Manufacturer for Induction Furnace Cooling Systems Revealed

piece:Induction Furnace Cooling System: The Secret Behind Efficient Metal MeltingInduction furnaces are among the most innovative and effective ways of melting metals, and they operate by using electromagnetic induction to heat up and melt metals. Unlike traditional furnaces that rely on heating elements, induction furnaces produce heat through electromagnetic currents, making them more efficient, faster, and safer than their conventional counterparts.However, as with most advanced technologies, they come with a few maintenance challenges. One of the most significant challenges is maintaining the ideal operating temperature through the efficient cooling of the system. If an induction furnace's temperature exceeds the recommended levels, it can cause severe damage to the furnace, resulting in costly repairs or even machine replacement.To prevent this from happening, induction furnace manufacturers need to integrate the best cooling systems, preferably those from a reliable cooling system manufacturer, to ensure optimal furnace performance.For those in search of the best induction furnace cooling system manufacturer, look no further than the leading cooling system company. The company is a global player in the cooling system industry, with a reputation for designing and manufacturing innovative and high-quality cooling systems for various industrial applications.The company's induction furnace cooling systems are designed to provide a reliable, stable, efficient, and cost-effective cooling solution for all types of furnaces, including induction furnaces. They provide the necessary cooling capacity, whether for continuous or intermittent operations, ensuring prolonged furnace life, enhanced performance, and increased productivity.One of the most significant advantages of the company's induction furnace cooling systems is their energy efficiency. The cooling systems are designed to operate with lower power consumption while still maintaining optimal cooling capacity. This translates to lower energy bills and reduced carbon footprint, which is excellent news for environmentally conscious furnace operators.In addition to their energy efficiency, the cooling systems are designed for ease of installation and maintenance, thanks to the modular design and user-friendly interface. The company's commitment to excellent customer service means that they provide comprehensive pre and post-installation support to customers, including on-site installation and training, and remote troubleshooting and maintenance services.The company's induction furnace cooling systems have proven reliability, having been subjected to rigorous testing and inspection before release to the market. They are made from the highest quality materials and components, ensuring durability, functionality, and performance consistency.The company's cooling systems feature cutting-edge technologies, such as intelligent temperature control, real-time monitoring, and automatic adjustment of cooling capacity. These technologies prevent overheating, drastic temperature changes, and other furnace malfunctions that could cause damage to the equipment or the melted metals.In conclusion, induction furnaces are an excellent option for industrial metal melting applications, and the cooling system is a crucial component to ensure optimal furnace performance. While several induction furnace cooling system manufacturers are available in the market, the leading cooling system company stands out from the crowd for their energy efficiency, reliability, durability, and functionality. Their induction furnace cooling systems provide a reliable and efficient cooling solution for all furnace types while ensuring extended furnace life, productivity, and enhanced performance. Contact the company today for a bespoke induction furnace cooling system to suit your furnace's unique needs.