Electric melting furnace: A Guide to Understanding the Process

By:Admin

With over 20 years of experience in the industry, Melting Furnace Electric has built a reputation for delivering high-quality and innovative melting solutions to a wide range of industrial sectors. Their team of engineers and technicians are dedicated to continuous research and development, ensuring that their products stay at the forefront of technology and meet the evolving needs of their customers.

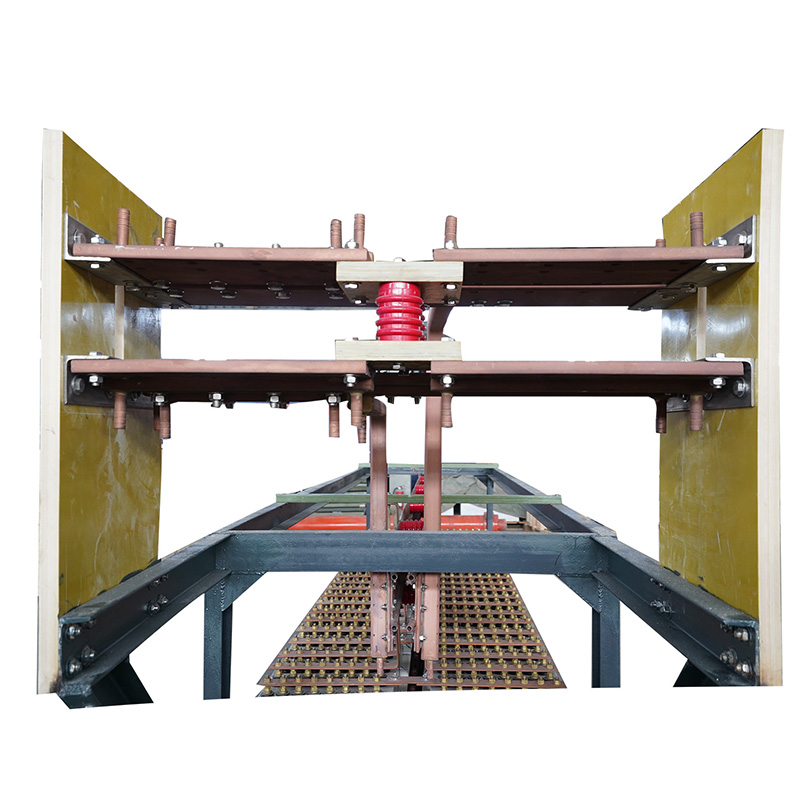

The new electric melting furnace is the result of years of research and development, and represents a significant advancement in the field of industrial melting equipment. The furnace is designed to be highly energy-efficient, using advanced electric heating elements to melt metals and alloys at precise temperatures with minimal energy consumption. This not only helps to reduce operating costs for industrial facilities, but also minimizes the environmental impact of the melting process.

In addition to its energy efficiency, the new furnace also boasts a high level of precision and control. Equipped with state-of-the-art temperature sensors and programmable controls, the furnace allows for precise temperature regulation and melting processes, ensuring the consistency and quality of the melted metals and alloys. This level of control is crucial for industries that require precise metallurgical properties in their finished products.

Furthermore, the electric melting furnace is designed with ease of use and maintenance in mind. The user-friendly interface and remote monitoring capabilities make it easy for operators to monitor and adjust the melting process, while the robust construction and minimal moving parts reduce the need for frequent maintenance and repairs. This ultimately translates to higher uptime and productivity for industrial facilities.

One of the key advantages of the new furnace is its versatility. It is capable of melting a wide range of metals and alloys, including aluminum, copper, brass, and various specialty alloys used in industries such as automotive, aerospace, and metal fabrication. This flexibility makes it a valuable asset for facilities that work with diverse materials, allowing them to consolidate their melting processes into a single, efficient solution.

"We are thrilled to introduce our latest electric melting furnace to the market," said the spokesperson for Melting Furnace Electric. "This furnace represents a significant leap forward in terms of energy efficiency, precision, and versatility. We believe it will be a game-changer for industrial facilities that rely on efficient and reliable melting processes for their production."

In line with their commitment to customer satisfaction, Melting Furnace Electric provides comprehensive support and service for their products. From installation and commissioning to technical support and maintenance, their team of experts is on hand to ensure that their customers get the most out of their melting furnace.

The new electric melting furnace from Melting Furnace Electric is now available for order, and the company is already seeing strong interest from a wide range of industries. With its advanced technology, energy efficiency, and versatility, the furnace is poised to set a new standard for industrial melting equipment and provide significant benefits for manufacturers and fabricators around the world.

Company News & Blog

Top Suppliers for High-Quality Induction Metal Melting Furnaces Revealed in Latest News

Induction metal melting furnaces have proved to be a game-changer in the metal industry because of their amazing precision, speed, and efficiency. However, the reliability of these furnaces depends on the suppliers that provide them. As such, finding the best induction metal melting furnace suppliers can be challenging. Fortunately, some companies have a proven track record of providing high-quality and reliable induction metal melting furnaces. One such company is a global leader in the manufacture and supply of induction metal melting furnaces, heat treatment, and forging systems. With years of experience in the industry, they have ensured that their furnaces provide extremely high time and energy efficiency. They specialize in the design and manufacture of induction furnaces that are utilized in a diverse range of heat treatment and melting applications. Their state-of-the-art induction metal melting furnaces are designed to cater to the needs of a wide range of industries such as automotive, aerospace, and defense, among others. Their commitment to quality has made them a preferred supplier for both small-scale and large-scale projects. Their team of engineers and technicians work together to create superior induction furnaces that meet the highest industry standards in terms of quality, efficiency, and reliability. They offer a comprehensive range of induction metal melting furnaces such as medium frequency and high-frequency induction furnaces, vacuum and atmospheric pressure melting furnaces, and more. The medium frequency induction furnace is ideal for melting low melting-point alloys such as aluminum, zinc, and bronze, among others. This type of furnace offers high melting efficiency and has an automatic temperature control system. On the other hand, the high-frequency induction furnace is suitable for melting high melting-point alloys such as steel, iron, and copper, among others. This furnace offers excellent temperature control, and the speed of melting is higher than that of medium frequency induction furnaces. In addition to their induction metal melting furnaces, they also provide heat treatment equipment for various industries. Their heat treatment equipment includes quenching systems, preheating systems, grinding systems, and more. Their heat treatment equipment is designed to meet the specific requirements of each customer, ensuring maximum efficiency and accuracy. They also provide forging systems, which are utilized in automotive, aerospace, and defense applications. Their forging systems provide excellent temperature control, high productivity, and low maintenance. They are also energy-efficient, reducing the carbon footprint of the metal industry. In conclusion, best induction metal melting furnace suppliers are critical to the success of any metal industry project. With the right supplier, a company can be sure of getting high-quality and reliable induction furnaces that cater to their specific needs. This is where the expertise of the global leader in the manufacture and supply of induction metal melting furnaces, heat treatment, and forging systems comes in. With their commitment to quality and a proven track record in the industry, they have become a preferred supplier of induction furnaces for various industries. Their comprehensive range of furnaces, heat treatment equipment, and forging systems cater to the requirements of diverse industries, ensuring maximum efficiency and accuracy.

Top Supplier of Zinc Melting Furnaces Offers Premium Quality Equipment

article on the benefits and features of their zinc melting furnaces.Melting furnaces are an integral part of manufacturing industries where they’re used for melting metals like zinc, lead, or aluminum. Among these metals, zinc is the most commonly used material, and a high-quality melting furnace is essential for the metal production process. This is where the Best Zinc Melting Furnace Supplier comes into play. They’re a leading manufacturer of premium-quality zinc melting furnaces that are designed to meet the diverse needs of different industries.The Best Zinc Melting Furnace Supplier believes that their zinc melting furnaces are an ideal solution to all the melting needs of manufacturing industries. Their furnaces are designed to provide a high-performance, efficient, and affordable melting experience. Their products have a reputation in the industry for their durability, efficiency, and reliability, making them a popular choice among industries that require efficient and reliable melting furnaces.One of the key features of the Best Zinc Melting Furnace Supplier’s furnaces is their flexibility. The furnaces can be used to melt a range of materials other than zinc, including copper, brass, and aluminum. They’ve been designed to meet the varied melting requirements of different industries, and thus the furnaces themselves come in different shapes and sizes as well.Their furnaces have a unique heating system, which directly melts the metal. The furnace heats the metal through the use of an internal heating element that is directly in contact with the metal. This process is highly efficient, ensuring that the metal melts quickly, which translates into greater productivity for the manufacturing industry.Another unique feature of the Best Zinc Melting Furnace Supplier’s furnaces is the high-quality materials used to manufacture them. The furnaces are constructed using high-quality raw materials, which ensures that the furnace is durable, long-lasting, and resistant to wear and tear. This means that the furnace can withstand repeated usage over extended periods without any risk of malfunctioning.Furthermore, their furnaces have a temperature controller that ensures the metal is melted at the right temperature. The temperature controller can be manually set using a thermostat or automatic controls that are easy to use. This means that the melting process can be carefully monitored and controlled, resulting in high-quality, well-melted metal that meets the required industry standards.The Best Zinc Melting Furnace Supplier’s product range also boasts of features such as an easy-to-remove crucible, which simplifies the process of transferring the molten metal. The crucibles have been designed to be quickly and easily removed, allowing for quick cleaning and maintenance. This feature not only ensures that the furnace is always clean and well-maintained, but it also means that the furnace requires less downtime, thereby increasing productivity.As mentioned earlier, the Best Zinc Melting Furnace Supplier’s products come in different shapes and sizes. They have portable furnaces that are ideal for small-scale industrial use and large-scale furnaces that cater to the needs of large manufacturing industries that require large amounts of molten metal. This ensures that customers can choose the perfect furnace that suits their specific requirements.To summarize, the Best Zinc Melting Furnace Supplier has always emphasized quality, innovation, and affordability when it comes to their products. They’ve continually set themselves apart from their competitors by producing high-quality, reliable, and efficient furnaces that cater to the needs of diverse industries. Their products’ durability, flexibility, and unique heating system have made them a popular choice among manufacturing industries worldwide. With the Best Zinc Melting Furnace Supplier, industries can be assured of a trustworthy and competent partner in their journey towards efficiency and success.

Top Chinese Manufacturer of Digital Melting Furnaces Offers Premium Quality Products to Global Market

[News]Digital Melting Furnace Manufacturer in China: Revolutionizing the Metal Industry[City, Date] - With the steady rise in global demand for metal products, Chinese digital melting furnace manufacturers have stepped up their game by innovating advanced technology and providing industry-leading solutions. One such company, which demands attention, is a leading manufacturer in China, revolutionizing the metal industry with their cutting-edge digital melting furnace technology.Founded several decades ago, this company has proven itself as a pioneer in the field of digital melting furnaces. Their vision to transform the way metals are melted and molded has set them apart from their competitors. By constantly pushing the boundaries of innovation and embracing new technologies, they have carved out a significant position in the market.The core principle behind the success of this company lies in their commitment to producing high-quality, energy-efficient, and technologically advanced digital melting furnaces. Their extensive range of products includes induction melting furnaces, gas-fired melting furnaces, electric arc furnaces, and vacuum arc melting furnaces, among others. This wide variety allows their customers to choose the furnace best suited to their specific requirements.One of the primary advantages of their digital melting furnaces is their precise temperature control, resulting in higher efficiency and reduced energy consumption. The incorporation of advanced sensors and an automated control system ensures accurate temperature control, eliminating any guesswork or manual errors. This not only saves valuable energy but also guarantees better quality metal output.Furthermore, the incorporation of digital interfaces and user-friendly controls has simplified the operation of these melting furnaces. The intuitive touch-screen displays, along with comprehensive manuals and online support, make it easy for operators to understand and operate the equipment efficiently.In line with their commitment to sustainability, this manufacturer has also integrated eco-friendly features into their digital melting furnace range. Advanced filtration systems remove harmful emissions, reducing environmental impact. By adopting these measures, companies using these digital melting furnaces can proudly contribute to a greener and cleaner industry.The advantages of this company's digital melting furnaces are already being recognized by major players in the metal industry. Their furnaces have become the go-to choice for industries involved in recasting, foundries, and research laboratories across the globe. The versatility of their products allows these manufacturers to cater to a wide range of metal alloys and applications.To support their customers, the company maintains an excellent customer service department. Their team of experienced professionals ensures prompt and reliable after-sales support, including technical assistance and spare parts availability. This commitment to customer satisfaction has earned them a strong reputation both domestically and internationally.Looking to the future, this manufacturer remains committed to continuous improvement and innovation. R&D efforts are constantly underway to explore new materials, enhance furnace productivity, and develop smarter solutions for the metal industry. They aim to solidify their position as the leading digital melting furnace manufacturer not just in China but around the world.With their unwavering commitment to quality, energy efficiency, and technological advancement, this digital melting furnace manufacturer from China is revolutionizing the metal industry. They have set a benchmark for others to follow, reinforcing China's position as a global manufacturing powerhouse. As the demand for metal products continues to grow, the advanced solutions provided by this industry-leading manufacturer will prove invaluable to professionals and businesses alike.About [Company Name]:[Company Name] is a renowned digital melting furnace manufacturer headquartered in China. With decades of experience, they specialize in providing advanced technological solutions for the metal industry. Their commitment to innovation, quality, and customer satisfaction has made them a trusted name not just in China but internationally. For more information, visit [Company Website].

The Leading Electric Melting Furnace Factory in China

China Electric Melting Furnace Factory, a leading manufacturer in the field of electric melting furnaces, has been making significant strides in the industry. With a track record of providing high-quality and efficient products, the factory has become a preferred choice for businesses in various sectors.Established in 2005, China Electric Melting Furnace Factory has continuously evolved and expanded its product range to meet the growing demands of the market. The company specializes in the design, development, and production of electric melting furnaces that are used for a wide range of applications, including metal melting, heat treatment, and material testing.One of the key factors that sets the factory apart is its commitment to innovation and continuous improvement. The company has invested heavily in research and development to ensure that its products are at the forefront of technological advancements. This dedication to innovation has resulted in the creation of cutting-edge electric melting furnaces that are highly efficient and environmentally friendly.In addition to its focus on product innovation, China Electric Melting Furnace Factory places a strong emphasis on quality control. The factory has implemented stringent quality management systems to ensure that every product that leaves its facility meets the highest standards. This unwavering commitment to quality has earned the factory a stellar reputation for reliability and performance.Furthermore, the factory also takes pride in its customer-centric approach. It strives to understand the unique needs and challenges of each of its clients and provides tailored solutions to meet their specific requirements. This customer-focused mindset has enabled the factory to build long-lasting relationships with clients from diverse industries, including automotive, aerospace, and manufacturing.As part of its efforts to stay ahead of the competition, China Electric Melting Furnace Factory has been proactive in adopting sustainable practices. The factory has integrated eco-friendly technologies into its manufacturing processes to minimize its environmental impact. This includes the use of energy-efficient equipment and the implementation of recycling initiatives to reduce waste.The dedication to sustainability has not only benefited the environment but has also resulted in cost savings for the factory. By optimizing its operations and reducing its resource consumption, China Electric Melting Furnace Factory has been able to offer competitive pricing to its clients without compromising on the quality of its products.Looking ahead, China Electric Melting Furnace Factory is poised for continued growth and success. The factory is constantly exploring new opportunities to expand its product portfolio and enter new markets. By leveraging its expertise and capabilities, the company aims to solidify its position as a global leader in the electric melting furnace industry.In conclusion, China Electric Melting Furnace Factory has established itself as a reputable and forward-thinking manufacturer of electric melting furnaces. With a focus on innovation, quality, customer satisfaction, and sustainability, the factory has proven itself as a reliable partner for businesses seeking high-performance melting solutions. As the company continues to push the boundaries of technological advancement, it is well-positioned to shape the future of the industry and meet the evolving needs of its clients.

Top Copper Melting Furnace Manufacturers in China for Electric Furnaces

China Electric Copper Melting Furnace Manufacturers Innovate to Meet Growing DemandAs the demand for copper continues to rise, China Electric Copper Melting Furnace Manufacturers have been working diligently to innovate their technologies in order to meet the needs of the market. With copper being an essential material in a variety of industries, including electronics, construction, and transportation, the need for efficient and effective copper melting furnaces has never been greater.One such company at the forefront of this innovation is a leading manufacturer in China. With a commitment to providing high-quality and cutting-edge electric copper melting furnaces, they have been dedicated to researching and developing new technologies to improve the efficiency and effectiveness of their products.The company has a long history of producing top-of-the-line electric copper melting furnaces, and their commitment to innovation has only strengthened their position in the market. By leveraging the latest advancements in technology and engineering, they have been able to produce furnaces that not only meet the current demand for copper, but also anticipate future trends in the industry.One of the key areas of focus for the company has been to improve the energy efficiency of their furnaces. By developing advanced heating and insulation systems, they have been able to reduce the energy consumption of their furnaces while maintaining high levels of productivity. This not only benefits the environment by reducing carbon emissions, but also provides cost savings for their customers.In addition to energy efficiency, the company has also placed a strong emphasis on the quality and purity of the copper produced by their furnaces. By implementing advanced purification and filtration systems, they have been able to ensure that the copper produced is of the highest quality, meeting the strict standards of their customers in various industries.Furthermore, the company has also integrated smart technology into their furnaces, allowing for remote monitoring and control. This not only improves the safety and ease of operation of their furnaces but also allows for real-time data analysis, enabling their customers to optimize their production processes and further improve efficiency.With their commitment to innovation, quality, and sustainability, the company has established themselves as a leader in the electric copper melting furnace manufacturing industry. Their dedication to meeting the needs of their customers and the market at large has positioned them for continued success and growth in the future.Looking ahead, the company has stated their commitment to continuing to invest in research and development, with a focus on further improving the energy efficiency, quality, and smart capabilities of their furnaces. Additionally, they have expressed their dedication to collaborating with their customers to understand their evolving needs and ensure that their products continue to meet and exceed expectations.As the demand for copper continues to grow, the importance of innovative and efficient electric copper melting furnaces cannot be overstated. With China Electric Copper Melting Furnace Manufacturers at the forefront of this innovation, the industry is well-equipped to meet the challenges and opportunities that lie ahead.

Best Supplier for Induction Furnace Frequencies

Induction furnaces have revolutionized the world of metallurgy and manufacturing, providing a highly efficient and cost-effective alternative to traditional methods of melting and pouring metal. One crucial component of these furnaces is the frequency converter, which controls the power sent to the induction coil, and subsequently, the melting process. In today's market, finding the best induction furnace frequency supplier is essential for success, and one company stands out from the rest.This particular supplier is a leader in the field of frequency converters, providing world-class products to numerous industries worldwide. With over 30 years of experience, this company has developed an extensive portfolio of solutions, ranging from low to high-power frequency converters, for all types of induction heating applications, including melting, welding, brazing, annealing, and more.Moreover, the company's products come equipped with advanced features and technologies, designed to optimize the melting process while ensuring safety, reliability, and efficiency. Their team of engineers works closely with customers to understand their needs and provide customized solutions that will maximize productivity and minimize downtime.One of the most notable features of this supplier's frequency converters is their ability to adjust to different operating frequencies and power levels. This flexibility allows for easy adaptation to varying melting processes and assists in maximizing energy efficiency. Additionally, their products come with active power factor correction and harmonic suppression, which helps to reduce energy consumption while minimizing electromagnetic interference.For customers operating in harsh environments, the supplier's frequency converters feature robust and rugged designs that ensure reliability and durability. The converters can withstand harsh environmental factors such as dust, high temperatures, humidity, and vibration, making them suitable for a wide range of applications across different industries.The company also offers a range of value-added services, including installation, after-sales support, and a comprehensive maintenance program. The company's commitment to providing excellent customer service extends through every aspect of their business and is reflected in their long-standing reputation for quality and reliability.Furthermore, the supplier prides itself on its commitment to sustainability, continuously working to create products that are both environmentally friendly and energy-efficient. Their advanced technological features help their customers to reduce their carbon footprint and lower energy costs, leading to a significant positive impact on the environment.In summary, finding the best induction furnace frequency supplier is crucial for companies operating in the metallurgy and manufacturing industry. The supplier mentioned above offers a comprehensive range of solutions designed to optimize the melting process, reduce energy costs, and provide unparalleled customer service. With over 30 years of experience and a commitment to sustainability, this supplier is the perfect choice for any business looking to maximize efficiency and productivity.

Affordable and Reliable Smelting Machines Now Available for Sale

Title: Revolutionary Smelting Machine Offers Cutting-Edge Solutions to Industrial SectorIntroduction:In the world of industrial manufacturing, advancements in technology continue to shape the way businesses operate and innovate. One such revolutionary development is the introduction of a state-of-the-art smelting machine that promises to redefine the smelting process. This groundbreaking innovation offers an array of benefits, ranging from improved efficiency and reduced energy consumption to minimal environmental impact. Here, we delve into the features and advantages of this cutting-edge smelting machine and its potential impact on the industrial sector.(Company Introduction):Leading the charge in technological breakthroughs, the renowned company {} has unveiled their latest creation, a next-generation smelting machine. With a long-standing reputation for excellence and innovation, {} has consistently driven the industry forward with their cutting-edge solutions. The introduction of this advanced smelting machine further solidifies their position as pioneers in industrial manufacturing.Impeccable Design and Operations:The newly developed smelting machine boasts an impeccable design that combines precision engineering with advanced automation. This fusion ensures enhanced performance levels while reducing the likelihood of errors. Built with industry-leading materials, the machine ensures durability and longevity, even under demanding operating conditions.Efficiency and Cost Reduction:By integrating the latest technological advancements, the smelting machine offers unmatched efficiency, leading to significant cost reductions for manufacturers. The machine optimizes the smelting process by minimizing resource wastage and maximizing output. Additionally, its intelligent monitoring system enables real-time analysis, allowing for swift identification of any inefficiencies or defects.Reduced Environmental Impact:Recognizing the pressing issue of environmental sustainability, {} has prioritized developing a smelting machine that aligns with eco-friendly practices. The advanced emissions control system incorporated into the machine helps minimize air pollution by filtering harmful substances. Furthermore, the machine's energy-efficient design reduces carbon emissions, contributing to a greener and more sustainable manufacturing process.Enhanced Safety Features:Safety is of utmost importance in modern industrial operations, and {} understands this well. The smelting machine comes equipped with a comprehensive range of safety features to ensure the well-being of workers and prevent accidents. The incorporation of state-of-the-art sensors and early-warning systems guarantee prompt response and risk mitigation, creating a secure work environment.Seamless Integration and Customization:Recognizing the diverse needs of different industries, {} has developed the smelting machine to seamlessly integrate with existing manufacturing processes. Whether it is in the steel, aluminum, or other metal industries, the machine's adaptability allows for easy incorporation and customization. This flexibility ensures minimal disruptions during installation and facilitates smooth operation tailored to specific production requirements.Benefits for Industrial Sector:The introduction of this groundbreaking smelting machine promises to revolutionize the industrial sector on multiple fronts. Manufacturers can experience increased production efficiency, reduced operational costs, and minimized energy consumption. Additionally, the improved environmental impact will contribute to sustainable manufacturing practices, thereby promoting a greener future for the industry.Market Outlook and Potential:With the increasing demand for efficient and sustainable manufacturing practices, the market potential for the {} smelting machine is vast. As more companies seek innovative solutions to improve their production processes, this cutting-edge technology offers a competitive advantage. Moreover, the positive environmental impact aligns perfectly with the growing global emphasis on reducing carbon footprints and adopting eco-friendly practices.Conclusion:The introduction of the state-of-the-art smelting machine by {} marks a significant milestone in the industrial manufacturing sector. Its impeccable design, efficiency, reduced environmental impact, and enhanced safety features position it as a game-changer in the industry. As manufacturers embrace this innovative technology, they can harness its benefits to optimize their operations, reduce costs, and contribute to a sustainable future. With the continued pursuit of excellence and innovation, {} remains at the forefront of transforming the industrial manufacturing landscape.

Top Copper Smelting Furnace for Superior Results

The demand for copper smelting furnaces has been on the rise in recent years, and one of the best options available in the market is the advanced copper smelting furnace offered by a leading manufacturer. This particular furnace is highly efficient and is designed to meet the smelting needs of large-scale copper production facilities. With its advanced technology and superior performance, it has quickly become a preferred choice for many industrial companies worldwide.The [company name] has established itself as a trusted name in the manufacturing and supply of industrial furnaces. With a strong focus on innovation and quality, the company has been able to develop and deliver cutting-edge furnace solutions to its customers across the globe. The company's commitment to excellence and customer satisfaction has earned it a solid reputation in the industry, making it a preferred partner for businesses seeking reliable and efficient smelting solutions.One of the key features that set the [company name]'s copper smelting furnace apart from its competitors is its advanced design and technology. The furnace is equipped with state-of-the-art heating elements and temperature control systems, allowing for precise and efficient smelting processes. This ensures that the furnace can handle large quantities of copper ore, producing high-quality molten copper ready for further processing. Additionally, the furnace is designed for easy operation and maintenance, minimizing downtime and maximizing productivity for its users.In addition to its technical capabilities, the [company name]'s copper smelting furnace also stands out for its eco-friendly features. The furnace is designed to minimize energy consumption and reduce emissions, making it a sustainable and environmentally responsible choice for businesses. With a growing emphasis on sustainable production practices, this aspect of the furnace has been well-received by companies looking to reduce their environmental impact while maintaining high levels of production efficiency.Furthermore, the [company name] provides comprehensive support and services for its copper smelting furnace, including installation, training, and ongoing technical assistance. This ensures that customers can fully maximize the potential of the furnace and achieve optimal performance in their smelting operations. The company's team of experts is dedicated to providing personalized solutions and assistance, helping customers integrate the furnace seamlessly into their production processes.The global demand for copper continues to grow as the metal plays a crucial role in various industries, including construction, electronics, and renewable energy. As a result, the need for efficient and reliable copper smelting furnaces has become increasingly important for businesses looking to meet the rising demand for copper products. The [company name]'s advanced copper smelting furnace offers a promising solution for companies seeking to enhance their smelting capabilities and stay competitive in the market.In conclusion, the [company name]'s copper smelting furnace is a top-of-the-line solution for businesses in need of high-performance smelting equipment. With its advanced technology, eco-friendly design, and comprehensive support services, the furnace represents a significant advancement in the field of copper smelting. As the demand for copper continues to rise, the [company name]'s furnace stands ready to meet the production needs of businesses worldwide, offering a reliable and efficient solution for copper smelting operations.

Leading Furnace Manufacturers Providing Superior Melting Solutions

Superbmelt Furnace Manufacturers, a leading innovator in the field of advanced metal melting and casting solutions, has emerged as a prominent player in the industry. With a commitment to excellence, Superbmelt Furnace Manufacturers has revolutionized the manufacturing process, providing superior quality and reliability to its clients. By utilizing cutting-edge technology and a focus on customer satisfaction, the company has cemented its position as a trusted partner for businesses across various sectors.At Superbmelt Furnace Manufacturers, the pursuit of perfection is ingrained in every aspect of the company's operations. They specialize in the design, development, and production of a wide range of melting furnaces that cater to the diverse needs of their clients. These furnaces are equipped with advanced features, including precise temperature controls, energy efficiency, and ease of use. Whether it is melting gold, silver, platinum, or other precious metals, Superbmelt Furnace Manufacturers offers reliable, efficient, and safe solutions.One of the most prominent products offered by Superbmelt Furnace Manufacturers is their electric gold melting furnace. Designed to meet the demands of the jewelry and mining industries, this furnace utilizes electric heating elements to ensure optimal melting temperatures for gold. The advanced control system allows for precise temperature settings, ensuring the integrity of the gold during the melting process. Additionally, the electric gold melting furnace boasts an energy-efficient design, reducing operational costs for businesses.Superbmelt Furnace Manufacturers also caters to the needs of the recycling industry with their induction metal melting furnace. This furnace utilizes induction heating to rapidly melt various metals, including copper, aluminum, and steel. The induction technology offers numerous advantages, such as uniform heating, improved metallurgical control, and reduced energy consumption. With its ability to efficiently melt and recycle scrap metal, the induction metal melting furnace helps businesses save costs and reduce environmental impact.Apart from melting furnaces, Superbmelt Furnace Manufacturers also produces a range of casting machines that enable the creation of intricate metal objects with precision. Their vacuum casting machine, for instance, utilizes vacuum-assisted casting technology to produce high-quality castings free from porosity and defects. This process ensures the creation of flawless metal parts, meeting the stringent quality requirements of industries such as aerospace, automotive, and jewelry manufacturing.Superbmelt Furnace Manufacturers not only focuses on delivering exceptional products but also provides comprehensive after-sales service and technical support to their clients. Their team of experienced technicians offers on-site installation, training, and maintenance services, ensuring that customers can make the most of their investment. Additionally, the company maintains a readily available stock of spare parts, guaranteeing minimal downtime in case of any equipment malfunction.With a global reach and an established reputation, Superbmelt Furnace Manufacturers has successfully served customers from a wide range of industries worldwide. Their commitment to innovation, reliability, and customer satisfaction has made them a preferred choice for businesses seeking advanced metal melting and casting solutions. As the industry continues to evolve, Superbmelt Furnace Manufacturers is well-positioned to push the boundaries of what is possible, empowering businesses with state-of-the-art technologies for their metal melting and casting needs.In conclusion, Superbmelt Furnace Manufacturers has firmly established itself as a leading player in the field of advanced metal melting and casting solutions. With their cutting-edge technologies, commitment to excellence, and comprehensive customer support, the company continues to drive innovation and set new standards in the industry. As businesses strive for efficiency and reliability in their operational processes, Superbmelt Furnace Manufacturers stands ready to provide world-class melting and casting solutions to meet their evolving needs.

Innovative Aluminium Rotary Furnace Manufacturers Redefine Industry Standards

Aluminium Rotary Furnace Manufacturers, a leading supplier in the metal processing industry, has announced a new line of advanced rotary furnaces aimed at increasing efficiency and sustainability in the production of aluminium. With a focus on innovation and cutting-edge technology, the company is set to revolutionize the way aluminium is processed and manufactured.The new line of rotary furnaces is designed to meet the growing demand for sustainable and efficient aluminium production. With a focus on reducing energy consumption and minimizing environmental impact, Aluminium Rotary Furnace Manufacturers is committed to providing state-of-the-art solutions for the metal processing industry.The company's advanced rotary furnaces incorporate the latest in technological advancements, offering improved performance and efficiency. By utilizing innovative design and engineering, Aluminium Rotary Furnace Manufacturers has developed a range of furnaces that are capable of delivering superior results while minimizing energy consumption and emissions.In addition to their focus on sustainability, Aluminium Rotary Furnace Manufacturers places a strong emphasis on quality and reliability. Each furnace is meticulously engineered and tested to ensure that it meets the highest standards of performance and durability. This commitment to excellence has earned the company a reputation as a trusted and reliable supplier in the industry.With a dedicated team of experts and professionals, Aluminium Rotary Furnace Manufacturers is committed to providing exceptional customer service and support. From initial consultation to ongoing maintenance and technical support, the company strives to meet the unique needs of each client and ensure their satisfaction with the product and service.In line with its commitment to innovation, Aluminium Rotary Furnace Manufacturers continues to invest in research and development to further improve its products and services. By staying ahead of the curve and anticipating the needs of the industry, the company is well-positioned to remain a leader in the market for years to come.The launch of the new line of advanced rotary furnaces is a testament to Aluminium Rotary Furnace Manufacturers' dedication to providing sustainable and efficient solutions for the aluminium production industry. With a strong focus on innovation, quality, and customer satisfaction, the company is poised to make a significant impact on the market and set new standards for the industry.Through its relentless dedication to excellence and commitment to sustainability, Aluminium Rotary Furnace Manufacturers has established itself as a leading supplier of rotary furnaces in the metal processing industry. With a focus on innovation, quality, and customer satisfaction, the company is well-positioned to remain at the forefront of the market for years to come.As the demand for sustainable and efficient aluminium production continues to grow, Aluminium Rotary Furnace Manufacturers is poised to meet the needs of the industry with its new line of advanced rotary furnaces. With a focus on innovation, quality, and customer satisfaction, the company is committed to providing exceptional solutions for the metal processing industry and setting new standards for the future.