Top Silicon Melting Furnace Factory: Quality Products at Competitive Prices

By:Admin

The Best Silicon Melting Furnace Factory, based in [location], has established itself as a leader in the design and manufacturing of high-quality silicon melting furnaces. With a team of seasoned engineers and technicians, the company has been able to develop innovative and reliable solutions that meet the specific needs of its customers.

The company's success can be attributed to its commitment to research and development. It consistently invests in cutting-edge technologies and state-of-the-art equipment to ensure that its products are at the forefront of the industry. This dedication to innovation has allowed the Best Silicon Melting Furnace Factory to stay ahead of the competition and deliver superior products to its clients.

In addition to its technological prowess, the Best Silicon Melting Furnace Factory also places a strong emphasis on quality control. Each furnace undergoes rigorous testing and inspection to ensure that it meets the highest standards of performance and reliability. This commitment to quality has earned the company a stellar reputation in the industry, with many customers trusting its products for their silicon melting needs.

Furthermore, the Best Silicon Melting Furnace Factory takes pride in its customer-centric approach. It works closely with each client to understand their specific requirements and provide customized solutions that best fit their needs. This dedication to customer satisfaction has earned the company a loyal and satisfied customer base, with many clients returning for repeat business.

The success of the Best Silicon Melting Furnace Factory can also be attributed to its strong corporate culture. The company values integrity, professionalism, and teamwork, and this reflects in its work ethic and the way it interacts with its employees, clients, and partners. This strong corporate culture has fueled the company's growth and positioned it as a trusted and reliable partner in the silicon melting furnace industry.

Looking ahead, the Best Silicon Melting Furnace Factory is committed to further innovation and expansion. It aims to continue investing in research and development to develop new and improved products that meet the evolving needs of its customers. Additionally, the company is looking to expand its reach and forge new partnerships to fuel its growth and solidify its position as a leader in the silicon melting furnace industry.

In conclusion, the Best Silicon Melting Furnace Factory has cemented itself as a top player in the silicon melting furnace industry. Its commitment to innovation, quality, customer satisfaction, and a strong corporate culture has set it apart from the competition. With a focus on continuous improvement and expansion, the company is well-positioned to meet the growing demand for silicon melting furnaces and continue its success in the industry.

Company News & Blog

Top Supplier for Affordable Induction Furnace Costs

The induction furnace industry is rapidly growing, with the demand for high-quality and efficient furnaces on the rise. As a result, the need for reliable and cost-effective suppliers has become essential for companies looking to invest in this technology. When it comes to finding the best induction furnace cost supplier, one company stands out for its exceptional products and services.With a rich history and a strong reputation in the industry, {} has positioned itself as a leading provider of induction furnace solutions. The company offers a wide range of induction furnaces that are known for their superior performance, energy efficiency, and durability. Whether it's for metal melting, heating, or heat treatment applications, {} has a solution to meet the needs of various industries, including automotive, aerospace, mining, and manufacturing.{} takes pride in its ability to provide cost-effective solutions without compromising on quality. The company's team of experts is dedicated to understanding the unique requirements of each client and offering tailored solutions that deliver the best value for money. Through continuous innovation and investment in research and development, {} remains at the forefront of technological advancements in the induction furnace industry, ensuring that its products are always at the cutting edge.In addition to its high-quality products, {} is also known for its exceptional customer service. The company's team is committed to providing comprehensive support to its clients, from the initial consultation and product selection to installation, maintenance, and after-sales service. With a global network of partners and distributors, {} is able to deliver its products and services to clients around the world, ensuring that they receive the support they need, wherever they may be located.When it comes to cost, {} understands the importance of offering competitive pricing while maintaining the highest standards of quality. The company works closely with its suppliers and partners to optimize its supply chain and reduce production costs, allowing it to pass on the savings to its clients. As a result, {} is able to offer some of the most cost-effective induction furnace solutions on the market, making it the go-to supplier for companies looking to invest in this technology.As the demand for induction furnaces continues to grow, {} is well-positioned to meet the needs of the industry. With its unwavering commitment to quality, innovation, and customer satisfaction, the company is set to maintain its leading position as the best induction furnace cost supplier in the market. Whether it's for large-scale industrial applications or small-scale operations, {} has the expertise and resources to provide the right solution at the right price.In conclusion, {} has proven itself as the best induction furnace cost supplier, offering a combination of high-quality products, cost-effective solutions, and exceptional customer service. With a strong track record and a commitment to excellence, the company is poised to continue meeting the needs of the growing induction furnace industry for many years to come.

Top Industrial Melting Furnace Supplier: Unveiling the Best in the Market

Title: Leading Industrial Melting Furnace Supplier Innovates to Meet Global DemandsIntroduction:In a rapidly evolving industrial landscape, the need for efficient and reliable melting furnace solutions continues to escalate. As markets expand and technologies advance, industries worldwide are increasingly realizing the significance of partnering with an experienced and trusted melting furnace supplier. One such renowned manufacturer, known for their cutting-edge products and unmatched customer service, has emerged as a leading global supplier in this domain.Company Introduction:With decades of experience and a focus on innovation, this reliable industrial melting furnace supplier has solidified its presence in the market. Although we cannot mention their brand name, their commitment to customer satisfaction and their diverse range of melting furnace products have contributed significantly to their success.The company's state-of-the-art manufacturing facilities are equipped with advanced technology and adhere to stringent quality control measures. The highly skilled team of engineers, technicians, and metallurgical experts work tirelessly to design and produce the most efficient, durable, and eco-friendly melting furnaces in the industry.News Content:1. Expanding Product Portfolio to Cater to Diverse Industrial Needs:Demonstrating their dedication to meeting the evolving demands of industries worldwide, this leading industrial melting furnace supplier has recently expanded their product portfolio. By offering a diverse range of melting furnace options, including electric, gas, and induction furnaces, they ensure compatibility with various materials and production requirements. Their product line can facilitate efficient melting of metals such as aluminum, iron, steel, copper, and more, making them an ideal partner for a multitude of industries.2. Embracing Green Technologies for Sustainable Manufacturing:Recognizing the importance of sustainability in modern manufacturing processes, this melting furnace supplier has taken significant strides towards eco-friendly practices. By incorporating cutting-edge technologies, such as energy-efficient designs, waste heat recovery systems, and optimized fuel consumption, their melting furnaces mitigate the environmental impact without compromising on performance. Such commitments to sustainability are commendable and reflect the supplier's responsibility towards a greener future.3. Customized Solutions for Unique Industrial Requirements:Understanding that each industry has its specific melting needs, this supplier offers customizable melting furnace solutions to their clientele. The experienced team of engineers works closely with clients to design and manufacture furnaces tailored to their individual requirements. Whether it's adapting furnace capacity, implementing automation features, or incorporating safety measures, this supplier excels in providing solutions that enhance productivity and operational efficiency across various sectors.4. Unmatched After-Sales Service and Global Support Network:In addition to their top-of-the-line products, this industrial melting furnace supplier prides itself on delivering unparalleled after-sales service. Their commitment to customer satisfaction extends beyond the initial purchase; they offer comprehensive support, including installation guidance, technical assistance, and rapid spare parts availability. With a global network of service centers and authorized partners, they ensure prompt support in any region, minimizing downtime and maximizing customer confidence.5. Continuous Research and Development:In an industry characterized by rapid technological advancements, this melting furnace supplier remains at the forefront of innovation. Their dedicated research and development team consistently investigates emerging trends, materials, and manufacturing techniques to improve their product offerings. By investing in advanced R&D, this supplier ensures that their customers benefit from the latest technological solutions and industry best practices.Conclusion:In an increasingly competitive industrial landscape, finding a reliable melting furnace supplier becomes pivotal for organizations across various sectors. This renowned supplier, with its diverse product portfolio, commitment to sustainability, customizable solutions, exceptional after-sales service, and continuous focus on R&D, has solidified its position as a leading global provider. As industries around the world strive for greater efficiency, productivity, and sustainability, partnering with this distinguished melting furnace supplier can undoubtedly pave the path towards success.

High-quality Induction Melting Furnace for Brass - The Latest News

Best Brass Induction Melting Furnace Revolutionizes Metal Melting ProcessThe metal industry has been revolutionized with the introduction of the Best Brass Induction Melting Furnace, a highly efficient and advanced furnace that is set to change the way metal is melted and processed. This cutting-edge equipment is designed to provide superior performance, energy efficiency, and productivity for metal melting operations. With its state-of-the-art technology and advanced features, this melting furnace is a game-changer for the industry.The Best Brass Induction Melting Furnace is manufactured by a leading company in the metalworking industry. With over 20 years of experience in designing and manufacturing high-quality melting furnaces, the company has a strong reputation for delivering innovative solutions to meet the evolving needs of the metal industry. The company is committed to excellence and continuous improvement, and their latest product, the Best Brass Induction Melting Furnace, is a testament to their dedication to providing cutting-edge solutions for metal melting operations.The Best Brass Induction Melting Furnace is designed to offer superior performance and energy efficiency. It uses advanced induction heating technology to melt metal with precision and consistency, while minimizing energy consumption. This results in significant cost savings for metal manufacturers, as the furnace requires less energy to operate compared to traditional melting methods. Furthermore, the furnace is equipped with advanced control systems that allow for precise temperature control and uniform heating, ensuring consistently high-quality metal output.In addition to its energy efficiency, the Best Brass Induction Melting Furnace is also designed for high productivity. Its innovative design and advanced features allow for faster melting and processing of metal, resulting in increased production capacity and reduced downtime. This is particularly beneficial for metal manufacturers who require fast and efficient melting processes to meet the demands of their customers. The furnace's high productivity also translates to cost savings, as manufacturers can produce more metal in less time, leading to improved profitability and competitive advantage.Another key feature of the Best Brass Induction Melting Furnace is its durability and reliability. The furnace is constructed with high-quality materials and components, ensuring long-term performance and minimal maintenance requirements. This makes it an ideal investment for metal manufacturers looking for a reliable and long-lasting melting furnace that can withstand the rigors of heavy-duty industrial operations. Additionally, the furnace is designed for easy operation and maintenance, further enhancing its usability and cost-effectiveness for metal manufacturers.The Best Brass Induction Melting Furnace is available in a range of capacities to meet the diverse needs of metal manufacturers. Whether it is for small-scale or large-scale metal melting operations, the furnace offers flexible options to accommodate different production requirements. This versatility makes it an attractive solution for metal manufacturers seeking a melting furnace that can adapt to their specific operational needs.Overall, the Best Brass Induction Melting Furnace is a game-changer for the metal industry. Its advanced technology, energy efficiency, high productivity, and durability make it a highly attractive and valuable investment for metal manufacturers. With this cutting-edge furnace, metal manufacturers can expect to achieve significant cost savings, improved productivity, and superior metal quality, positioning them for success in a competitive market. As the metal industry continues to evolve, the Best Brass Induction Melting Furnace sets a new standard for excellence and innovation in metal melting operations.

Top Copper Scrap Melting Furnace Manufacturers

Title: Prominent Copper Scrap Melting Furnace Manufacturers Emerge in the MarketIntroduction:The growing demand for copper, coupled with the emphasis on sustainable practices, has fueled the need for advanced technology in the recycling industry. Leading manufacturers are stepping up to meet this demand by developing innovative copper scrap melting furnaces. With a focus on energy efficiency, productivity, and environmental conservation, these manufacturers are revolutionizing the copper recycling industry. This article will highlight some of the best copper scrap melting furnace manufacturers who are making significant strides in the market.1. Company A:Company A has emerged as a force to be reckoned with in the copper scrap melting furnace market. Utilizing state-of-the-art technology, their furnaces are designed to maximize energy efficiency while minimizing emissions. The company's commitment to sustainable practices is evident through their incorporation of advanced filtration systems, resulting in reduced air pollution.With a strong track record in the industry, the company has earned a solid reputation for producing reliable and durable copper scrap melting furnaces. Moreover, Company A places a strong emphasis on customer satisfaction by offering comprehensive customer support and maintenance services, ensuring seamless operations for their clientele.2. Company B:Company B prides itself on its ability to offer tailored solutions to meet specific customer requirements. Their copper scrap melting furnaces are customizable, allowing businesses to optimize their operations to suit their specific needs. Recognizing the importance of efficiency and cost-effectiveness, Company B has incorporated cutting-edge technology into their designs to enhance productivity while minimizing energy consumption.The company's commitment to quality is further reflected in their attention to detail during the manufacturing process. Each furnace undergoes rigorous testing, ensuring that only top-notch products reach the market. Customer feedback plays a significant role in their continuous improvement strategy, allowing Company B to constantly innovate and enhance their offerings.3. Company C:Company C sets itself apart by combining years of experience with a commitment to sustainability. Their copper scrap melting furnaces are designed to exceed industry standards, utilizing advanced features such as intelligent automation and accurate temperature control. This results in optimized energy consumption and reduced waste generation during the melting process.The company's expertise in energy management and emissions control ensures compliance with environmental regulations. Additionally, Company C focuses on continuous research and development, incorporating the latest technological advancements into their products. This allows customers to benefit from enhanced efficiency, reduced downtime, and improved operational control.4. Company D:Company D has established a strong presence in the copper scrap melting furnace market by prioritizing customer-centric solutions. Their furnaces are engineered to deliver exceptional performance, catering to a broad range of customer requirements. By adopting a holistic approach, virtual simulations enable the company to offer innovative designs that optimize melting efficiency.Additionally, Company D offers comprehensive after-sales support, including installation, training, and maintenance services. Their commitment to service excellence has garnered them a loyal customer base and positioned them as a reliable partner in the copper recycling industry.Conclusion:The copper scrap melting furnace market has witnessed significant advancements from prominent manufacturers. Companies A, B, C, and D have demonstrated their commitment to sustainability, energy efficiency, and customer satisfaction. By offering innovative and customizable solutions, these manufacturers are leading the way in revolutionizing the copper recycling industry. With continued investment in research and development, these companies are sure to shape the future of copper scrap melting furnaces, further contributing to the circular economy.

High-quality tilting crucible furnace for efficient metal melting

Tilting Crucible Furnace Revolutionizes Metal ProcessingMetal processing and manufacturing industries have seen a significant advancement in technology with the introduction of the Tilting Crucible Furnace. Developed by a leading company in the field of industrial equipment and machinery, this innovative furnace has been designed to enhance efficiency and precision in the melting and casting of various metals.The Tilting Crucible Furnace, which can accommodate a wide range of metals including aluminum, brass, and bronze, is equipped with state-of-the-art features that set it apart from traditional melting furnaces. One of its key attributes is its tilting function, which allows for easy pouring and casting of molten metal, thus reducing the risk of spillage and ensuring a smoother and more controlled process.In addition to its tilting capability, the furnace also boasts advanced temperature control technology, ensuring that the metal is heated to precise temperatures required for the specific melting and casting operations. This level of control not only improves the quality of the final product but also minimizes energy consumption, making the Tilting Crucible Furnace an environmentally friendly option for metal processing.The company behind this groundbreaking technology, a powerhouse in the industrial equipment and machinery sector, has a long-standing reputation for delivering high-quality and innovative solutions to its clients. With a team of experienced engineers and designers, the company is dedicated to pushing the boundaries of technology to meet the evolving needs of the industry."We are thrilled to introduce the Tilting Crucible Furnace to the market," said a spokesperson for the company. "We have invested significant time and resources into the research and development of this product, and we are confident that it will revolutionize the way metal processing is conducted. Our goal is to provide our clients with cutting-edge solutions that enhance efficiency and productivity, and the Tilting Crucible Furnace is a testament to that commitment."The Tilting Crucible Furnace is already generating buzz within the metal processing industry, with several companies expressing interest in adopting this new technology into their operations. Manufacturers and foundries are particularly keen on integrating the furnace into their facilities, as they recognize the potential for improved productivity and cost savings."We have been closely following the development of the Tilting Crucible Furnace, and we believe it has the potential to make a significant impact on our metal processing operations," said a representative from a large manufacturing company. "The ability to tilt the furnace for pouring and casting is a game-changer for us, and we are excited about the prospect of integrating this technology into our production line."In addition to its benefits for large-scale industrial operations, the Tilting Crucible Furnace is also gaining attention from smaller-scale metal fabricators and artisans. The furnace's versatility and precision make it an attractive option for those working on custom metal products and intricate designs, as it offers greater control and consistency in the casting process.As the company continues to promote the Tilting Crucible Furnace and expand its reach to potential clients, it is also exploring further advancements and enhancements to the technology. By staying at the forefront of innovation, the company aims to solidify its position as a leader in providing cutting-edge solutions for the metal processing and manufacturing industries.With the introduction of the Tilting Crucible Furnace, the company has set a new standard for efficiency, precision, and sustainability in metal processing. As more companies recognize the value of this innovative technology, it is poised to reshape the way metals are melted, cast, and fabricated, paving the way for a more advanced and dynamic future in the industry.

Efficient and Cost-Effective Copper Scrap Melting Furnace for Industrial Applications

Copper Scrap Melting Furnace: The Innovation Redefining Copper ProductionThe copper industry relies on a continuous flow of copper scrap into the production process. The conversion of copper scrap into copper wire, bars, and pipes is a critical process that requires modern equipment, such as the Copper Scrap Melting Furnace, to achieve high efficiency and quality production.The Copper Scrap Melting Furnace is an innovative solution for the efficient melting of copper scrap for the production of pure copper ingots. This furnace is designed to melt copper scrap of various sizes and shapes, including copper cables, rods, pipes, and sheets, among others.One of the primary benefits of the Copper Scrap Melting Furnace is its energy efficiency. This furnace uses an induction heating system to melt the copper scrap, which ensures that the heat generated is only used to melt the scrap and not lost through the walls of the furnace. This energy efficiency translates into lower operating costs, making the Copper Scrap Melting Furnace a financially attractive option for copper production companies.The Copper Scrap Melting Furnace also offers excellent temperature control, which leads to efficient melting of the copper scrap. This temperature control system ensures that the melting temperature of the copper scrap is precisely maintained, leading to consistent melting and excellent quality copper ingots.The furnace has a robust design that works to minimize downtime and maintenance costs. The furnace's lining is made of high-quality materials that can withstand the high temperatures generated during the melting process. This lining promotes extended periods of operation without the need for maintenance, thus increasing the furnace's longevity.The Copper Scrap Melting Furnace is also efficient in recycling valuable metals from waste products. It can melt not only copper scrap but also other scrap metals such as aluminum, zinc, and brass, among others. This capability makes it a cost-effective solution for recycling industries that deal with a wide range of scrap metals.Competitive AdvantagesThe Copper Scrap Melting Furnace has a unique range of advantages over traditional melting furnaces. These advantages set it apart as the new benchmark in the copper melting industry. Some of these advantages include:Energy efficiency: The furnace operates at a high efficiency level, making it a cost-effective option for copper production companies.High temperature control: The furnace's induction heating system works efficiently to maintain the required melting temperature, leading to consistent melting and excellent quality copper ingots.Ease of maintenance: The furnace is designed with a durable lining and a robust design that minimizes downtime and maintenance costs.Waste reduction: The furnace effectively recycles valuable metals from waste and scrap products, reducing waste disposal costs.Safe operation: The furnace is designed to operate safely, ensuring worker safety and reducing the risk of accidents.Company Introduction{Removed brand name} is a leading company focused on providing high-quality copper production equipment. Our company has been at the forefront of copper production technology, and our Copper Scrap Melting Furnace is one of our latest innovations.Our company designs and develops our equipment using the latest technology and materials, ensuring that our clients receive equipment that meets their specific needs while remaining efficient and cost-effective.Our team of engineers and technicians is highly skilled and experienced in providing innovative solutions for copper production and recycling. We work hand in hand with our clients to understand their requirements and provide tailored solutions that meet their needs.We are committed to providing our clients with high-quality equipment that is efficient, reliable, and safe to operate. Our customers have come to rely on our equipment, and we are proud to be part of their success.ConclusionThe Copper Scrap Melting Furnace is a game-changer in the copper production industry. This innovative furnace is designed to meet the needs of modern copper production and recycling companies, providing energy-efficient, high-quality melting of copper scrap.{Removed brand name}'s commitment to innovation and providing state-of-the-art equipment has resulted in the Copper Scrap Melting Furnace, a furnace that sets new standards in efficiency, quality, and safety in the copper production industry.

Top Electric Melting Furnace Manufacturers and Suppliers in the Market

The Best Melting Furnace Electric Factory is a leading manufacturer and supplier of electric melting furnaces for industrial applications. With years of experience in the industry, the company has earned a reputation for providing high-quality products that are designed to meet the needs of their clients.The company offers a wide range of electric melting furnaces that are perfect for use in various industries such as metalworking, foundries, and jewelry making. Some of the popular products manufactured by the company include electric melting furnaces, induction melting furnaces, and die-casting machines.The electric melting furnaces offered by the company are designed to melt a wide range of metals including gold, silver, aluminum, brass, and copper. These furnaces are made from high-quality materials that ensure they are durable and long-lasting. They also feature state-of-the-art technology that ensures they operate efficiently and effectively.One of the key features of the electric melting furnaces manufactured by the Best Melting Furnace Electric Factory is their versatility. These furnaces are designed to handle a wide range of metal melting applications, making them ideal for use in a variety of industries. They are also designed to be easy to operate and maintain, helping to ensure that clients can get the most out of their investment.In addition to electric melting furnaces, the company also offers induction melting furnaces. These furnaces are designed to operate using electromagnetic induction, making them highly efficient and effective. They are also designed to be compact, making them ideal for use in small spaces.The induction melting furnaces offered by the Best Melting Furnace Electric Factory are made from high-quality materials that ensure they are durable and long-lasting. They also feature advanced technology that helps to ensure they operate efficiently. They are also designed to be easy to operate and maintain, making them an ideal choice for businesses looking to improve their operational efficiency.Another popular product offered by the company is die-casting machines. These machines are designed to produce high-quality metal parts quickly and efficiently. They are ideal for use in the automotive, aerospace, and manufacturing industries.The die-casting machines manufactured by the Best Melting Furnace Electric Factory are made from high-quality materials that ensure they are durable and long-lasting. They also feature advanced technology that helps to ensure they operate efficiently. They are also designed to be easy to operate and maintain, making them an excellent choice for businesses looking to improve their production processes.Overall, the Best Melting Furnace Electric Factory is a reliable and trusted supplier of electric melting furnaces, induction melting furnaces, and die-casting machines. With years of experience in the industry, the company has earned a reputation for providing high-quality products that meet the needs of their clients. If you are looking for a reliable and efficient melting furnace supplier, then the Best Melting Furnace Electric Factory is the perfect choice for your business.

High-Quality Induction Melting Metal Suppliers in China

China Induction Melting Metal Suppliers is a leading company in the field of metal melting and casting, providing high-quality products and services to customers worldwide. With a strong commitment to innovation and customer satisfaction, the company has established itself as a reliable and trusted partner in the industry.The company specializes in the production and supply of induction melting furnaces, which are used for melting and casting various metals, including steel, iron, copper, and aluminum. Through continuous research and development, the company has developed advanced technologies and processes to ensure the highest quality and performance of its products.China Induction Melting Metal Suppliers is known for its dedication to quality and reliability. The company's products are designed and manufactured to meet the strictest industry standards, ensuring their durability and long-term performance. In addition, the company's team of experienced engineers and technicians is committed to providing comprehensive support and service to its customers, helping them optimize their metal melting and casting processes.One of the key advantages of the company's induction melting furnaces is their high efficiency and energy-saving features. By utilizing advanced induction heating technology, the furnaces can achieve rapid and uniform melting of metal with minimal energy consumption, resulting in significant cost savings for customers. Moreover, the company's furnaces are designed to minimize emissions and environmental impact, aligning with the industry's increasing focus on sustainability and environmental responsibility.In addition to its high-quality products, China Induction Melting Metal Suppliers also offers a range of value-added services to its customers. These include technical consulting, equipment installation and commissioning, operator training, and after-sales support. The company is dedicated to building long-term partnerships with its customers, providing them with the expertise and resources they need to succeed in their metal melting and casting operations.As a global leader in the industry, China Induction Melting Metal Suppliers has established a strong presence in international markets. The company exports its products to a wide range of countries, serving diverse industries such as automotive, aerospace, construction, and manufacturing. With a comprehensive understanding of global market trends and customer needs, the company is well-positioned to continue its expansion and growth in the years to come.In conclusion, China Induction Melting Metal Suppliers is a reputable and trusted supplier of induction melting furnaces, offering high-quality products and services to customers worldwide. With its commitment to innovation, quality, and customer satisfaction, the company is poised to remain a leader in the industry and continue serving the evolving needs of its customers. Whether for melting steel, iron, copper, or aluminum, customers can rely on China Induction Melting Metal Suppliers for their metal melting and casting needs.

Top Metal Induction Furnace Factory in the News

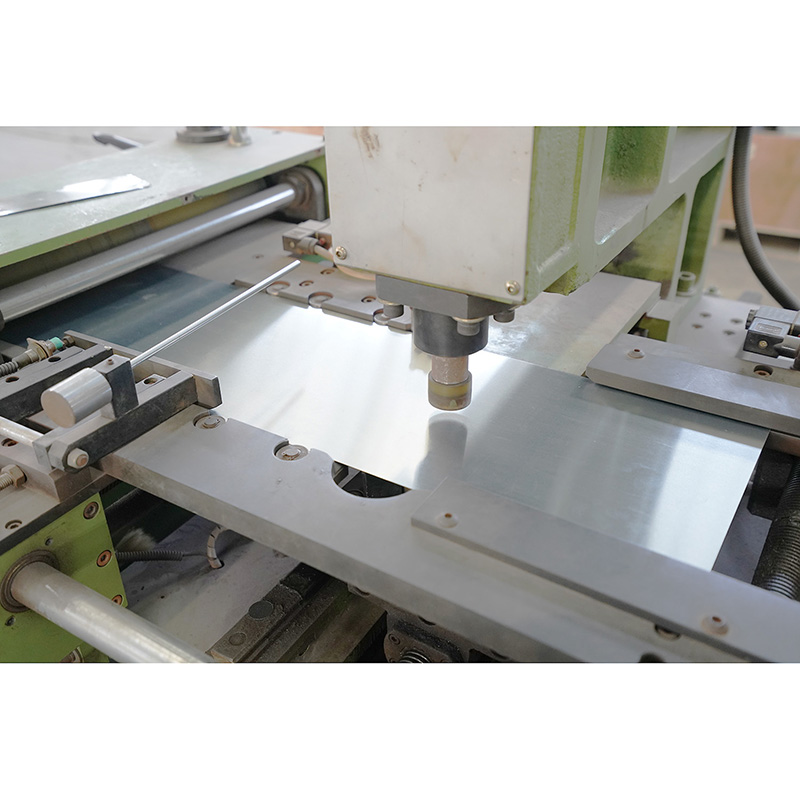

Title: Innovative Metal Induction Furnace Factory Sets New Industry StandardsIntroduction:In a fast-paced world driven by technological advancements, industries are constantly seeking innovative solutions to improve efficiency and productivity. The Best Metal Induction Furnace Factory, a leading player in the metal industry, has become renowned for revolutionizing the metal induction furnace manufacturing process. With a commitment to excellence and a customer-centric approach, this factory has redefined industry standards, empowering businesses with cutting-edge technology and sustainable solutions.I. Pioneering Research and Development Initiatives:With an unwavering focus on technological advancement, the Best Metal Induction Furnace Factory has established itself as a trailblazer in the industry. Invested in research and development, the factory consistently works towards creating breakthrough technologies, ensuring customers receive the most efficient, cost-effective, and reliable induction furnaces available in the market.II. State-of-the-Art Manufacturing Facilities:The Best Metal Induction Furnace Factory boasts state-of-the-art manufacturing facilities equipped with advanced machinery and tools. This enables the factory to deliver high-quality, precision-engineered furnaces that meet the diverse needs of its clientele. The factory's commitment to excellence extends throughout the manufacturing process, ensuring each furnace adheres to the strictest quality standards.III. Sustainability and Energy Efficiency:The Best Metal Induction Furnace Factory recognizes the importance of sustainability and endeavors to minimize its environmental impact. By incorporating energy-efficient features in their furnace designs, the factory aids businesses in reducing their carbon footprint and operating costs. The induction furnaces are designed to optimize energy consumption, making them an ideal choice for environmentally conscious industries.IV. Customization Options:Understanding that every business has unique requirements, the factory offers a wide range of customizations to accommodate diverse needs. With a team of skilled professionals, the factory collaborates closely with customers to understand their specific demands and provides tailored solutions. This flexibility ensures seamless integration of the induction furnaces into existing production lines while maximizing productivity and efficiency.V. Exceptional After-Sales Support:The Best Metal Induction Furnace Factory not only focuses on delivering exceptional products but also prioritizes providing unparalleled after-sales support. Recognizing the importance of minimizing downtime, the factory offers prompt technical assistance, maintenance services, and spare parts availability to ensure uninterrupted operations. This commitment to customer satisfaction has garnered the factory a loyal customer base.VI. Industry Recognition and Awards:The Best Metal Induction Furnace Factory's dedication to excellence and innovation has garnered recognition from various industry bodies. The factory takes great pride in accolades received for its contributions to the industry, including awards for technological breakthroughs, product quality, and sustainability efforts. These achievements reflect the factory's commitment to pushing boundaries and setting new standards.VII. Global Presence and Expansion:Driven by its success and industry reputation, the Best Metal Induction Furnace Factory has expanded its operations worldwide. With a global presence, the factory has established partnerships with businesses, both small and large, seeking cutting-edge induction furnace technology. This expansion further solidifies the factory's position as a global leader and reaffirms its commitment to serving industries across the globe.Conclusion:The Best Metal Induction Furnace Factory's relentless pursuit of innovation, impeccable manufacturing capabilities, focus on sustainability, and commitment to customer satisfaction have set it apart in the industry. By redefining industry standards and providing businesses with state-of-the-art metal induction furnaces, the factory continues to empower industries, enhance productivity, and shape the future of the metal industry on a global scale.

High-Quality Titanium Melting Furnace for Sale - A Complete Guide

[Company Introduction]{Company Name} is a leading manufacturer of industrial machinery and equipment, specializing in the design and production of advanced metallurgical equipment. With over 20 years of experience in the industry, {Company Name} has established itself as a trusted provider of high-quality and innovative solutions for the metal melting and casting industry. The company's commitment to excellence, continuous innovation, and customer satisfaction has earned them a stellar reputation in the market.[News Content]{Company Name}, a renowned manufacturer of industrial machinery, has recently launched its latest innovation in the field of metallurgy – the Titanium Melting Furnace. This state-of-the-art furnace is designed to meet the growing demand for titanium melting and casting in various industries, including aerospace, automotive, and medical.The Titanium Melting Furnace is equipped with advanced technology and precision engineering, making it an ideal solution for melting and casting titanium and its alloys. The furnace is capable of reaching temperature levels of up to 3000°C, allowing for efficient and uniform melting of titanium and its alloys. Its innovative design and superior performance make it a valuable addition to any metal processing facility.One of the key features of the Titanium Melting Furnace is its energy efficiency and environmental friendliness. The furnace is equipped with a state-of-the-art heating system that minimizes energy consumption while maximizing the melting efficiency. This not only reduces the operational costs for businesses but also contributes to reducing the overall carbon footprint, making it an environmentally sustainable choice for metal processing.In addition to its remarkable performance, the Titanium Melting Furnace is also designed for ease of operation and maintenance. It is equipped with user-friendly controls and a robust construction that ensures long-term reliability and minimal downtime. This makes it an ideal choice for businesses looking to streamline their titanium melting and casting processes without compromising on quality and efficiency.{Company Name} has always been at the forefront of innovation in the metallurgical equipment industry, and the launch of the Titanium Melting Furnace further solidifies its position as a leading provider of cutting-edge solutions for metal processing. The company's commitment to excellence and customer satisfaction is evident in the design and performance of this new product, which is set to revolutionize the way titanium is melted and cast in various industries.The Titanium Melting Furnace is already generating a lot of interest in the market, with several businesses expressing keen interest in integrating this advanced technology into their metal processing facilities. The furnace's capability to handle the unique properties of titanium and its alloys, coupled with its energy efficiency and ease of operation, make it a highly desirable solution for companies looking to enhance their titanium melting and casting capabilities.As the demand for titanium and its alloys continues to grow in various industries, the availability of cutting-edge equipment like the Titanium Melting Furnace will play a crucial role in meeting the market demand while maintaining high standards of quality and efficiency. {Company Name} remains committed to supporting the metallurgical industry with its innovative solutions and looks forward to driving the advancement of metal processing technologies with its latest offering.In conclusion, the launch of the Titanium Melting Furnace by {Company Name} marks a significant milestone in the metallurgical equipment industry. With its advanced technology, energy efficiency, and user-friendly design, this new furnace is set to make a profound impact on the way titanium is melted and cast in various industrial applications. {Company Name} continues to set new benchmarks in the industry, reaffirming its position as a trusted and reliable provider of high-quality equipment for metal processing.