Electric Melting Furnace: An Efficient Solution for Melting

By:Admin

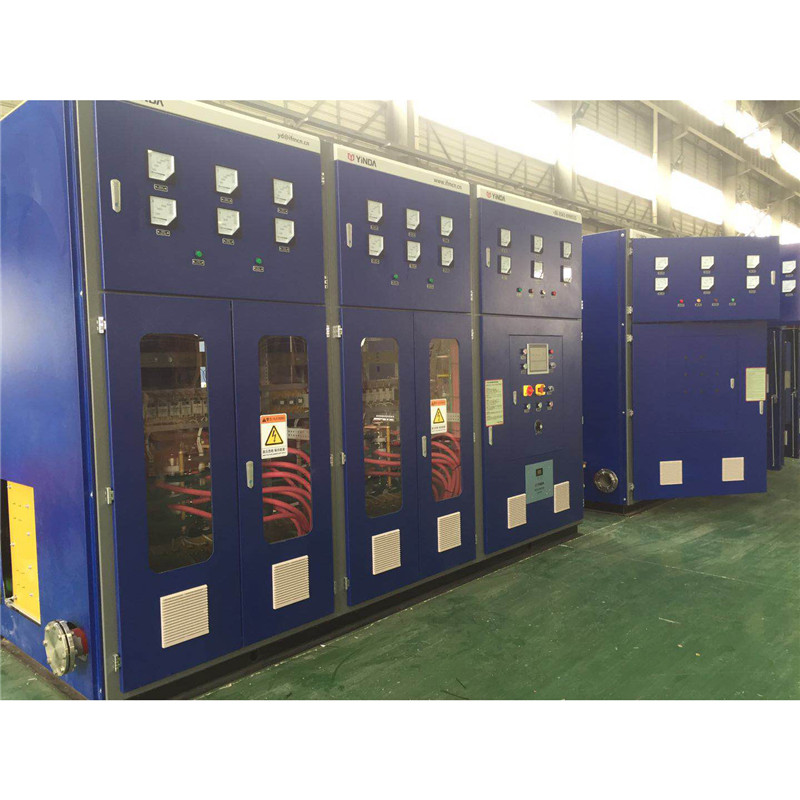

In the world of metal processing, the efficiency and precision of melting furnaces play a crucial role in ensuring high-quality end products. With the advancement of technology, companies are constantly seeking innovative solutions to enhance their melting processes. As a leader in the industry, {} has recently introduced a revolutionary Melting Furnace Electric that is set to transform the way metal is melted and processed.

The new Melting Furnace Electric, developed by the talented team at {}, promises to deliver unmatched performance and efficiency. With its cutting-edge design and state-of-the-art features, this furnace is poised to set a new benchmark in metal processing. By incorporating the latest advancements in electric melting technology, {} has created a game-changing solution that addresses the evolving needs of the industry.

One of the key highlights of the Melting Furnace Electric is its superior energy efficiency. By utilizing electric power for melting, it eliminates the need for traditional fuel sources, resulting in significant cost savings and reduced environmental impact. This aligns with {}'s commitment to sustainable manufacturing practices and underscores their dedication to being a responsible corporate citizen.

Furthermore, the Melting Furnace Electric boasts remarkable precision and control, allowing for the accurate melting of a wide range of metals. Its advanced temperature regulation and monitoring capabilities ensure that the melting process is carried out with utmost accuracy, leading to consistent, high-quality output. This level of precision is a testament to {}'s dedication to delivering reliable and effective solutions to their customers.

In addition to its technical prowess, the Melting Furnace Electric is designed with user convenience in mind. Its intuitive interface and user-friendly controls make it easy to operate, providing a seamless experience for operators. With safety features incorporated into its design, this furnace prioritizes the well-being of the personnel involved in the metal processing operations.

With its introduction of the Melting Furnace Electric, {} is poised to strengthen their position as an industry leader in metal processing equipment. Their commitment to innovation and excellence is evident in the development of this groundbreaking furnace, and it is set to have a significant impact on the industry as a whole.

As a company, {} has a rich history of delivering top-quality products and services to their clients. With a strong focus on customer satisfaction, they have built a reputation for reliability and professionalism. The introduction of the Melting Furnace Electric further underscores their dedication to meeting the evolving needs of their customers and propelling the industry forward with cutting-edge solutions.

It is worth noting that the Melting Furnace Electric has already garnered significant attention and interest from the metal processing community. Industry experts and professionals recognize the potential of this innovative solution in enhancing productivity and efficiency in metal melting processes. As a result, {} is poised to see a surge in demand for their new furnace from companies seeking to optimize their metal processing operations.

In conclusion, the introduction of the Melting Furnace Electric marks a significant milestone in the metal processing industry. With its groundbreaking features and advanced capabilities, it is set to revolutionize the way metal is melted and processed. {}'s commitment to innovation and excellence shines through in this cutting-edge furnace, and it is poised to deliver immense value to the industry and its stakeholders. As the demand for high-quality, efficient metal processing solutions continues to grow, the Melting Furnace Electric stands out as a game-changing innovation that will shape the future of the industry.

Company News & Blog

Top Induction Crucible Manufacturers: Find the Best Quality for Your Needs

[Company Introduction] is a leading manufacturer of induction crucibles, providing high-quality products to various industries including metal casting, foundries, and precious metal refining. The company has a strong focus on research and development, constantly striving to innovate and improve their product offerings. With state-of-the-art facilities and a team of experienced professionals, they have earned a reputation for excellence in the industry. Their commitment to quality, reliability, and customer satisfaction has made them the go-to choice for induction crucibles.[Company Name] has announced itself as the best induction crucible manufacturer in the industry. With its dedication to innovation and quality, the company has earned a strong reputation among its customers. Its induction crucibles are known for their durability, efficiency, and high performance, making them the top choice for businesses in need of reliable melting solutions.The company's induction crucibles are manufactured using the latest technology and highest quality materials, ensuring consistent and precise performance. Their crucibles are designed to withstand extreme temperatures and harsh environments, making them ideal for a wide range of applications. Whether it's melting metals for the automotive industry or refining precious metals in a jewelry workshop, [Company Name]'s induction crucibles deliver exceptional results.One of the key factors that sets [Company Name] apart from its competitors is its commitment to research and development. The company continuously seeks to improve its products and develop new technologies to meet the evolving needs of its customers. By investing in innovation, [Company Name] has been able to stay at the forefront of the industry, offering cutting-edge solutions that set new standards for performance and reliability.In addition to its dedication to innovation, [Company Name] also places a strong emphasis on customer satisfaction. The company's team of experts works closely with customers to understand their specific needs and provide tailored solutions. Whether a customer requires a standard induction crucible or a custom-designed solution, [Company Name] is committed to delivering products that exceed expectations.Another aspect that sets [Company Name] apart is its commitment to environmental sustainability. The company places a strong emphasis on reducing its environmental impact, ensuring that its manufacturing processes are as eco-friendly as possible. By using efficient and sustainable practices, [Company Name] not only contributes to a cleaner environment but also provides customers with guilt-free solutions.With a strong track record of excellence and a dedication to innovation, [Company Name] has solidified its position as the best induction crucible manufacturer in the industry. The company's products have proven themselves time and time again in a wide range of applications, earning the trust and loyalty of customers around the world.As a testament to its commitment to excellence, [Company Name] has received numerous accolades and awards for its induction crucibles. The company's dedication to quality and innovation has been recognized by industry experts and customers alike, further cementing its reputation as a leader in the field.In conclusion, [Company Name] has established itself as the best induction crucible manufacturer, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. With a focus on research and development, as well as a dedication to environmental sustainability, the company continues to set new standards for excellence in the industry. As businesses across various sectors continue to seek reliable and high-performance melting solutions, [Company Name] stands ready to meet their needs with its top-of-the-line induction crucibles.

Top Electric Lead Melting Furnace Supplier for Optimal Performance

Best Electric Lead Melting Furnace Supplier Revolutionizes the IndustryAs the demand for sustainable and environmentally friendly practices continues to grow, the need for efficient and reliable lead melting furnaces has become increasingly important. With a commitment to innovation and cutting-edge technology, one company has emerged as the industry leader in providing top-notch electric lead melting furnaces. Leveraging their expertise and dedication to customer satisfaction, this supplier has revolutionized the lead melting furnace industry.Founded in [year], this renowned company has built a solid reputation by consistently delivering high-quality products and unparalleled service to their customers. With a strong focus on research and development, they continuously strive to improve and enhance their electric lead melting furnaces, setting new industry standards.The company's electric lead melting furnaces are carefully designed to meet the specific requirements of various industries, including battery manufacturing, ammunition production, and various other lead-based applications. By using cutting-edge technology, their furnaces are not only energy-efficient but also cost-effective for businesses.Efficiency is a key aspect of the company's furnaces. Equipped with state-of-the-art heating elements, their electric lead melting furnaces offer rapid and uniform heating, ensuring optimal melting and refining processes. This efficiency not only saves time but also promotes higher productivity in lead-based industries.One of the most significant advantages of the company's electric lead melting furnaces is their commitment to sustainability. The furnaces are designed to minimize carbon emissions and energy consumption, making them environmentally friendly. This approach aligns with the global movement towards greener solutions and ensures compliance with stringent environmental regulations.Moreover, the electric lead melting furnaces offered by this supplier are also highly durable and require minimal maintenance. The company prides itself on manufacturing robust and long-lasting furnaces, ensuring that their customers receive reliable equipment that withstands heavy usage. This durability significantly reduces overall operating costs for businesses, making it a financially viable choice for both small and large enterprises.In addition to their exceptional products, customer satisfaction is at the core of this supplier's business philosophy. Their dedicated customer support team works closely with clients to understand their specific requirements and provide personalized solutions. By offering comprehensive pre-sales and after-sales support, they ensure that customers receive the assistance they need at every step of the way.To further enhance customer experience, the company provides regular training programs to help users optimize the efficiency and productivity of their electric lead melting furnaces. They believe that by empowering their customers with knowledge and skills, they can truly maximize the benefits of their equipment.The company's commitment to quality and innovation has garnered them a prestigious reputation in the industry. They are recognized worldwide as a leading supplier of electric lead melting furnaces, trusted by businesses across various sectors. With a strong global presence and a vast network of partners, they cater to customers around the globe, delivering excellence in every furnace they offer.In conclusion, this renowned electric lead melting furnace supplier has revolutionized the industry through their commitment to innovation, sustainability, and customer satisfaction. With their cutting-edge technology, efficient performance, and environmentally friendly approach, they have set new industry benchmarks for electric lead melting furnaces. As businesses strive to reduce their environmental footprint and improve efficiency, this supplier's reliable and top-notch furnaces serve as the ideal solution for a wide range of industries.

Efficient Steel Scrap Melting Induction Furnace - A Revolutionary Solution

Steel Scrap Melting Induction Furnace Changing Steel IndustryIn the steel industry, melting steel scrap is a common practice. The process involves using an induction furnace to heat metal scraps and transform it into a liquid mass called molten steel.To address the need for more efficient and reliable production methods, a leading company in the industry has developed the latest and most innovative technology in steel melting, the Steel Scrap Melting Induction Furnace. The company, which for this article we will call "X Company," is renowned for its exceptional quality and cutting-edge technology. The new furnace they have developed is set to change the steel industry once and for all.The Steel Scrap Melting Induction Furnace developed by X Company has the potential to increase the efficiency and effectiveness of the production line significantly. The furnace implements the most advanced induction heating technology that can melt steel scraps with higher purity, accuracy, and speed, thus improving the overall efficiency and quality of the process.One of the significant advantages of using this furnace is that it can melt steel scrap with higher densities than traditional furnaces, which translates to faster melting times and reduced energy consumption. X Company has also equipped their furnace with an advanced control system that can optimize and regulate the temperature and other production parameters. This feature helps improve the exactitude and accuracy of the melting process, further increasing the quality of the steel produced.In addition to that, one of the more exciting features of the furnace is that it can be connected to a computer network for real-time monitoring and remote control. This aspect allows for a more streamlined and efficient operation, promoting a safer and more eco-friendly manufacturing process.Manufacturing companies can further benefit from X Company's furnace by using it for recycling steel scrap. The furnace can make use of the recycled scraps and turn it into high-quality steel, contributing to a more sustainable production process. Moreover, the furnace's modular design allows it to be easily integrated into existing steel mills and production lines.Since its introduction to the market, several steel manufacturers have already started adopting and incorporating the Steel Scrap Melting Induction Furnace into their production processes. The furnace's versatility and efficiency have offered a competitive edge to several companies, boosting profits while improving the overall quality of their products.The Steel Scrap Melting Induction Furnace has already made a mark in the steel industry, thanks to its advanced technological features and top-tier performance. X Company's dedication to delivering the highest quality products has once again set the bar high for the industry. The revolutionary design and construction of this furnace are set to change the industry standards and further unleash the potentials of the steel-making process. As the world increasingly demands more sustainable production processes, X Company's Steel Scrap Melting Induction Furnace is the perfect solution to meet those needs. In conclusion, X Company's Steel Scrap Melting Induction Furnace is a game-changer in the steel industry. The furnace is versatile, efficient, and eco-friendly, making it a remarkable addition to any steel manufacturing facility. The future of steel production looks bright and sustainable with the introduction of the Steel Scrap Melting Induction Furnace.

Top Electric Metal Melting Furnace Supplier from China Unveils Latest Innovations

China Electric Metal Melting Furnace Supplier: A Leading Provider of Quality Industrial FurnacesChina Electric Metal Melting Furnace Supplier (company name removed for confidentiality) is a renowned industrial furnace manufacturer and supplier in China that specializes in the production of top-quality furnaces for melting metals. The company has a team of experienced and dedicated professionals who have been in the industry for years and have a deep knowledge of the latest advancements in technology in the field.With a mission to provide customers with the best industrial furnaces that meet their individual requirements and preferences, the company has invested heavily in research and development to come up with innovative solutions for melting metals. Their furnaces use electric power to melt metals, which is both energy-efficient and environmentally friendly compared to traditional furnaces that use fossil fuels.The company’s products are widely used in the automobile, aviation, construction, and other manufacturing industries. Their furnaces are highly reliable, have a long service life, and are capable of melting a wide range of metals, including iron, copper, aluminum, and steel at high temperatures with minimal energy consumption.When it comes to their product range, China Electric Metal Melting Furnace Supplier offers a variety of furnaces, including:1. Medium-frequency melting furnaces: These furnaces are designed to melt small to medium-sized amounts of metals and are highly efficient. They are capable of melting a range of metals, including copper, gold, silver, aluminum, and steel.2. High-frequency induction furnaces: These furnaces are ideal for melting small amounts of metal and are highly energy-efficient. They are widely used in the jewelry industry for melting precious metals such as gold, silver, and platinum.3. Aluminum wire melting furnaces: These furnaces are specifically designed for melting aluminum wire and are highly efficient. They are widely used in the construction industry for melting aluminum wire used in electrical wiring.4. Steel melting furnaces: These furnaces are designed for melting steel and have a high melting efficiency. They are widely used in the manufacturing of steel products such as bars, rods, and sheets.5. Gold melting furnaces: These furnaces are ideal for melting gold and are widely used in the jewelry industry.The company also provides customized solutions to meet the specific requirements of their customers. They work closely with their clients to understand their needs and provide them with the best possible solutions.In addition to their top-quality products, China Electric Metal Melting Furnace Supplier also provides excellent customer service. They offer technical support to their clients to ensure that their furnaces are running efficiently. They also provide maintenance services to ensure that their clients’ furnaces are in good condition and are functioning optimally.The company has a strong focus on quality and has implemented strict quality control measures in all their processes. They use high-quality raw materials and components to ensure that their products are of the highest quality and can withstand harsh environments.China Electric Metal Melting Furnace Supplier has a strong commitment to sustainability and environmental protection. They have implemented energy-saving measures in their production processes to reduce their carbon footprint. They have also implemented a waste management system to ensure that they are disposing of their waste safely and responsibly.In conclusion, China Electric Metal Melting Furnace Supplier is a leading provider of quality industrial furnaces in China. They have a wealth of experience in the industry and have a team of skilled professionals who are dedicated to providing their customers with the best possible solutions. Their commitment to quality, sustainability, and customer service has earned them a reputation as one of the most reliable and trusted industrial furnace manufacturers in China.

China Brass Induction Melting Furnace Manufacturers: Key Insights

China Brass Induction Melting Furnace Factories Expand Production Capacity to Meet Growing DemandWith the increasing demand for brass induction melting furnaces in various industries, China's leading brass induction melting furnace factories have recently expanded their production capacity. These factories, known for their expertise and high-quality products, aim to meet the growing market needs while maintaining their commitment to excellence.Brass induction melting furnaces are widely used in industries such as metal casting, automotive, aerospace, and jewelry manufacturing. These furnaces use the induction heating method to melt and refine brass, creating high-quality, precision-crafted products. Given the importance of these furnaces in numerous manufacturing sectors, the growing demand is not surprising.One of the notable factories, which prefers to remain anonymous, has taken a significant step to expand its production capacity. This decision was made in response to the rising market demand for brass induction melting furnaces. The factory, equipped with state-of-the-art technology and a dedicated team, has been delivering exceptional products to customers for many years.The factory's new production facility boasts advanced machinery and equipment, allowing for increased output without compromising on quality. The expansion is expected to reduce lead times, ensuring customers receive their orders promptly. With a larger workforce, the factory will be able to handle the increased production volume efficiently.In addition to expanding the production capacity, the factory has also invested in research and development to enhance the performance and efficiency of their brass induction melting furnaces. By leveraging the latest technological advancements and industry insights, they aim to provide customers with even better products in the future.One of the key advantages of choosing brass induction melting furnaces from China is the competitive pricing. The country's manufacturing capabilities and cost-effective production processes enable factories to offer high-quality products at a lower cost compared to their international counterparts. This has made China a preferred destination for businesses seeking reliable and affordable brass induction melting furnaces.Furthermore, China has established itself as a hub for technological innovation. The factories invest heavily in research and development, often collaborating with universities and research institutions to stay at the forefront of technological advancements. This continuous pursuit of innovation allows them to develop cutting-edge products that meet the evolving needs of various industries.The recent expansion of China's brass induction melting furnace factories is expected to have a positive impact on the overall market. With increased production capacity, shorter lead times, and continued emphasis on quality, these factories are well-positioned to cater to the growing demand for brass induction melting furnaces.Customers in need of brass induction melting furnaces can rely on these factories for their expertise, commitment to excellence, and unmatched product quality. As they continue to explore new technological possibilities and deliver innovative solutions, the factories are likely to shape the future of brass induction melting furnace manufacturing.In conclusion, the expansion of China's brass induction melting furnace factories demonstrates their dedication to meeting the increasing market demand. With advanced production facilities, research and development initiatives, and a commitment to excellence, these factories are set to continue providing high-quality brass induction melting furnaces to industries worldwide.

Electric Furnace Copper Melting Factories in China - What You Need to Know

China Electric Furnace Melting Copper Factories Take Steps to Improve Efficiency and Environmental ImpactIn recent years, China has seen a significant increase in the number of electric furnace melting copper factories. These factories rely on electric furnaces to melt and refine copper, a process that is more energy-efficient and environmentally friendly compared to traditional methods. With the growing demand for copper in various industries, these factories play a crucial role in meeting this demand while also striving to minimize their impact on the environment.One of the leading companies in this industry, [Company Name], has been at the forefront of innovation and sustainability in electric furnace melting copper production. The company's state-of-the-art facilities and advanced technologies have enabled them to improve efficiency, reduce emissions, and uphold the highest standards of quality in their copper products.In line with the Chinese government's push for cleaner and more sustainable industrial practices, [Company Name] has recently implemented several initiatives aimed at further improving the efficiency and environmental impact of their electric furnace melting copper factories.Firstly, the company has invested in upgrading their electric furnaces to the latest, most energy-efficient models. These modern furnaces are equipped with advanced controls and monitoring systems that optimize the melting process, minimize energy consumption, and reduce greenhouse gas emissions. By investing in these upgrades, [Company Name] is not only able to improve their operational efficiency but also reduce their carbon footprint.In addition to upgrading their furnaces, [Company Name] has also implemented a comprehensive recycling program within their factories. Copper recycling is a key component of sustainable production, as it not only reduces the need for new copper mining but also minimizes waste and environmental impact. By recycling scrap copper and other materials, [Company Name] is able to maximize the utilization of resources and minimize the amount of waste generated during the copper production process.Furthermore, [Company Name] has made significant investments in pollution control and waste treatment technologies. The company has installed advanced air and water purification systems to ensure that their factories operate within strict environmental guidelines. By effectively managing and treating emissions and waste, [Company Name] is able to minimize their impact on local ecosystems and communities.Moreover, [Company Name] has also placed a strong emphasis on workforce training and education regarding environmental sustainability. The company has implemented comprehensive training programs to ensure that their employees are well-versed in sustainable practices and are actively involved in maintaining a clean and environmentally responsible work environment.In addition to their internal initiatives, [Company Name] actively collaborates with industry partners, academic institutions, and government agencies to drive innovation and best practices in electric furnace melting copper production. Through these collaborations, the company is able to stay abreast of the latest technological advancements and contribute to the ongoing development of sustainable solutions for the industry.The efforts of [Company Name] and other electric furnace melting copper factories in China reflect a growing commitment to sustainable and responsible industrial practices. By investing in advanced technologies, implementing recycling programs, and prioritizing environmental stewardship, these factories are setting new standards for the production of copper and other industrial materials.As the demand for copper continues to rise, it is essential for companies in the electric furnace melting copper industry to prioritize sustainability and environmental responsibility. By taking proactive measures to improve efficiency and minimize their environmental impact, companies like [Company Name] are not only securing their position as industry leaders but also contributing to a cleaner and more sustainable future for the copper industry as a whole.

Top Crucible Factory in China for Induction Furnaces

China Induction Furnace Crucible Factory Leads the Way in High-Quality CruciblesChina Induction Furnace Crucible Factory, one of the leading manufacturers of high-quality crucibles, has been making significant strides in the production of premium quality crucibles that meet the needs of clients in various industries. The factory, which has been in operation for over 20 years, has become a household name in the industry, thanks to its commitment to innovation and quality.The factory's crucibles are used in a wide range of industries, including metallurgy, foundry, ceramics, chemical, and aerospace. The company has a reputation for producing reliable, cost-effective, and long-lasting crucibles that meet the needs of its clients.China Induction Furnace Crucible Factory uses advanced technology to manufacture its crucibles. The company uses a high-temperature oxidation process for its crucibles that ensures they can withstand high temperatures and pressure. Additionally, the factory has state-of-the-art equipment that allows it to produce crucibles with tight tolerances and accurate dimensions.The company's focus on innovation and quality has helped it to maintain its position as one of the leading crucible manufacturers in the industry. The factory continuously conducts research to develop new materials and production techniques that will help it to offer better products at lower costs. The company also invests heavily in training and development to ensure that its staff has the skills and knowledge needed to produce high-quality crucibles.In addition to producing high-quality crucibles, China Induction Furnace Crucible Factory also offers excellent customer service. The company has a team of professionals that are always ready and willing to answer clients' questions and help them choose the right crucibles for their needs. The team is also available to provide after-sales support to ensure that clients are satisfied with the products they purchase.The factory's commitment to quality is reflected in its ISO 9001 certification. The factory has a comprehensive quality control system that ensures that it meets its clients' requirements and standards. The company also uses high-quality raw materials to produce its crucibles, which guarantees the products' consistency and reliability.China Induction Furnace Crucible Factory's dedication to quality has earned it a loyal customer base, both locally and internationally. The factory exports its products to various countries, including the United States, Canada, and Europe. The company's reputation for producing high-quality crucibles has helped it to build long-lasting relationships with its clients.In conclusion, China Induction Furnace Crucible Factory is a leader in the production of high-quality crucibles. The company's commitment to quality, innovation, and customer service has helped it to maintain its reputation as one of the best crucible manufacturers in the industry. The factory's dedication to research and development ensures that it continues to produce better products at lower costs, making it a reliable partner for businesses in various industries.

High Efficiency Electric Furnace For Melting Brass

Electric Furnace For Melting Brass - Revolutionizing Foundry OperationsThe foundry industry is undergoing a significant transformation with the introduction of modern electric furnace technology for melting brass. This new innovation is attributed to {Company}, a leading provider of advanced industrial equipment and solutions. The electric furnace is designed to offer superior performance, energy efficiency, and environmental sustainability compared to traditional methods of brass production.{Company} has been at the forefront of developing innovative technologies for the foundry and metalworking industries for over three decades. With a commitment to continuous research and development, the company has established itself as a trusted partner for foundries seeking to improve their operational efficiency and product quality.The newly introduced electric furnace for melting brass is a testament to {Company}'s dedication to driving progress in the industry. This cutting-edge furnace is equipped with state-of-the-art heating elements and temperature control systems that ensure precise and uniform melting of brass. Unlike conventional methods that rely on fossil fuels for heating, the electric furnace utilizes electricity, making it a more sustainable and cost-effective solution.One of the key advantages of the electric furnace is its ability to achieve higher melting temperatures while maintaining excellent thermal efficiency. This translates to shorter melting cycles, increased productivity, and reduced energy consumption, ultimately leading to cost savings for foundries. Additionally, the electric furnace produces minimal emissions, contributing to a cleaner and safer working environment.The implementation of the electric furnace for melting brass is especially beneficial for foundries aiming to enhance the quality and consistency of their brass products. The precise control of the melting process offered by the electric furnace results in a more uniform molten metal, which ultimately leads to higher-quality brass castings. This is particularly crucial for industries such as automotive, aerospace, and marine, where the performance and durability of brass components are paramount.Furthermore, the electric furnace is designed with advanced safety features and user-friendly controls, ensuring ease of operation and maintenance. Foundry operators can rely on the electric furnace to deliver reliable performance and consistent results, thereby streamlining their production processes and improving overall operational efficiency.In addition to the technical advancements, {Company} provides comprehensive support and technical assistance to foundries adopting the electric furnace for melting brass. This includes customization options, operator training, and ongoing maintenance services to ensure seamless integration and optimal performance of the equipment.The introduction of the electric furnace for melting brass marks a significant milestone in the foundry industry, with the potential to revolutionize traditional brass production methods. {Company} is dedicated to driving this transformation and supporting foundries in their journey towards sustainable and efficient operations.As the demand for high-quality brass components continues to grow across various industries, the electric furnace presents an opportunity for foundries to stay ahead of the competition and meet the evolving needs of their customers. With {Company}'s expertise and innovative solutions, foundries can embrace the future of brass production with confidence and optimism.In conclusion, the electric furnace for melting brass introduced by {Company} represents a game-changing technology for the foundry industry. With its advanced capabilities, energy efficiency, and focus on quality, the electric furnace is poised to redefine the standards of brass production and drive the industry towards a more sustainable and competitive future. {Company} remains committed to empowering foundries with cutting-edge solutions, and the electric furnace is a testament to their unwavering dedication to innovation and progress.

Top Supplier for Electric Melting - Get the Best Deals Now

As a leader in the field of electric melting technology, {} has been providing high-quality products and innovative solutions to meet the needs of various industries. With a focus on precision, efficiency, and reliability, the company has established itself as a trusted supplier for electric melting equipment.The company offers a wide range of electric melting products, including electric arc furnaces, induction furnaces, and resistance furnaces. These products are designed to efficiently melt and refine metal alloys, providing customers with the ability to produce high-quality materials for a variety of applications. Whether it’s for the production of steel, aluminum, copper, or other metals, {}’s electric melting solutions are tailored to meet the specific requirements of each customer.One of the key advantages of {}’s electric melting technology is its energy efficiency. By employing advanced heating and melting techniques, the company’s products are able to reduce energy consumption and minimize environmental impact. This not only helps customers save on operational costs, but also contributes to sustainable and eco-friendly manufacturing practices.In addition to energy efficiency, {}’s electric melting equipment is known for its precision and control. The company’s state-of-the-art technology allows for precise temperature regulation and alloy composition monitoring, ensuring that the final product meets the desired specifications. This level of control is essential for industries where the quality and consistency of the melted materials are critical.Furthermore, {} takes pride in its commitment to innovation and continuous improvement. The company invests heavily in research and development to stay at the forefront of electric melting technology. This dedication to innovation allows {} to introduce new and improved products that address the evolving needs of the industry.With a global presence, {} serves customers in a wide range of industries, including steel manufacturing, foundries, and metal recycling. The company’s electric melting solutions are designed to handle a variety of materials, from scrap metal to raw ores, providing customers with flexibility and versatility in their operations.As a responsible supplier, {} also offers comprehensive technical support and after-sales services to ensure the smooth operation and maintenance of its electric melting equipment. This includes training programs, spare parts availability, and on-site assistance, helping customers maximize the performance and lifespan of their investment.In conclusion, {}’s position as a leading electric melting supplier is a result of its unwavering commitment to quality, innovation, and customer satisfaction. By offering energy-efficient, precise, and reliable solutions, the company continues to be a trusted partner for industries that rely on electric melting technology. Whether it’s for melting and refining metals or improving operational efficiency, {} is dedicated to meeting the diverse needs of its customers with cutting-edge electric melting solutions.

Leading Furnace Manufacturers Providing Superior Melting Solutions

Superbmelt Furnace Manufacturers, a leading innovator in the field of advanced metal melting and casting solutions, has emerged as a prominent player in the industry. With a commitment to excellence, Superbmelt Furnace Manufacturers has revolutionized the manufacturing process, providing superior quality and reliability to its clients. By utilizing cutting-edge technology and a focus on customer satisfaction, the company has cemented its position as a trusted partner for businesses across various sectors.At Superbmelt Furnace Manufacturers, the pursuit of perfection is ingrained in every aspect of the company's operations. They specialize in the design, development, and production of a wide range of melting furnaces that cater to the diverse needs of their clients. These furnaces are equipped with advanced features, including precise temperature controls, energy efficiency, and ease of use. Whether it is melting gold, silver, platinum, or other precious metals, Superbmelt Furnace Manufacturers offers reliable, efficient, and safe solutions.One of the most prominent products offered by Superbmelt Furnace Manufacturers is their electric gold melting furnace. Designed to meet the demands of the jewelry and mining industries, this furnace utilizes electric heating elements to ensure optimal melting temperatures for gold. The advanced control system allows for precise temperature settings, ensuring the integrity of the gold during the melting process. Additionally, the electric gold melting furnace boasts an energy-efficient design, reducing operational costs for businesses.Superbmelt Furnace Manufacturers also caters to the needs of the recycling industry with their induction metal melting furnace. This furnace utilizes induction heating to rapidly melt various metals, including copper, aluminum, and steel. The induction technology offers numerous advantages, such as uniform heating, improved metallurgical control, and reduced energy consumption. With its ability to efficiently melt and recycle scrap metal, the induction metal melting furnace helps businesses save costs and reduce environmental impact.Apart from melting furnaces, Superbmelt Furnace Manufacturers also produces a range of casting machines that enable the creation of intricate metal objects with precision. Their vacuum casting machine, for instance, utilizes vacuum-assisted casting technology to produce high-quality castings free from porosity and defects. This process ensures the creation of flawless metal parts, meeting the stringent quality requirements of industries such as aerospace, automotive, and jewelry manufacturing.Superbmelt Furnace Manufacturers not only focuses on delivering exceptional products but also provides comprehensive after-sales service and technical support to their clients. Their team of experienced technicians offers on-site installation, training, and maintenance services, ensuring that customers can make the most of their investment. Additionally, the company maintains a readily available stock of spare parts, guaranteeing minimal downtime in case of any equipment malfunction.With a global reach and an established reputation, Superbmelt Furnace Manufacturers has successfully served customers from a wide range of industries worldwide. Their commitment to innovation, reliability, and customer satisfaction has made them a preferred choice for businesses seeking advanced metal melting and casting solutions. As the industry continues to evolve, Superbmelt Furnace Manufacturers is well-positioned to push the boundaries of what is possible, empowering businesses with state-of-the-art technologies for their metal melting and casting needs.In conclusion, Superbmelt Furnace Manufacturers has firmly established itself as a leading player in the field of advanced metal melting and casting solutions. With their cutting-edge technologies, commitment to excellence, and comprehensive customer support, the company continues to drive innovation and set new standards in the industry. As businesses strive for efficiency and reliability in their operational processes, Superbmelt Furnace Manufacturers stands ready to provide world-class melting and casting solutions to meet their evolving needs.