Top Factories for Induction Melting Furnaces: Your Ultimate Guide

By:Admin

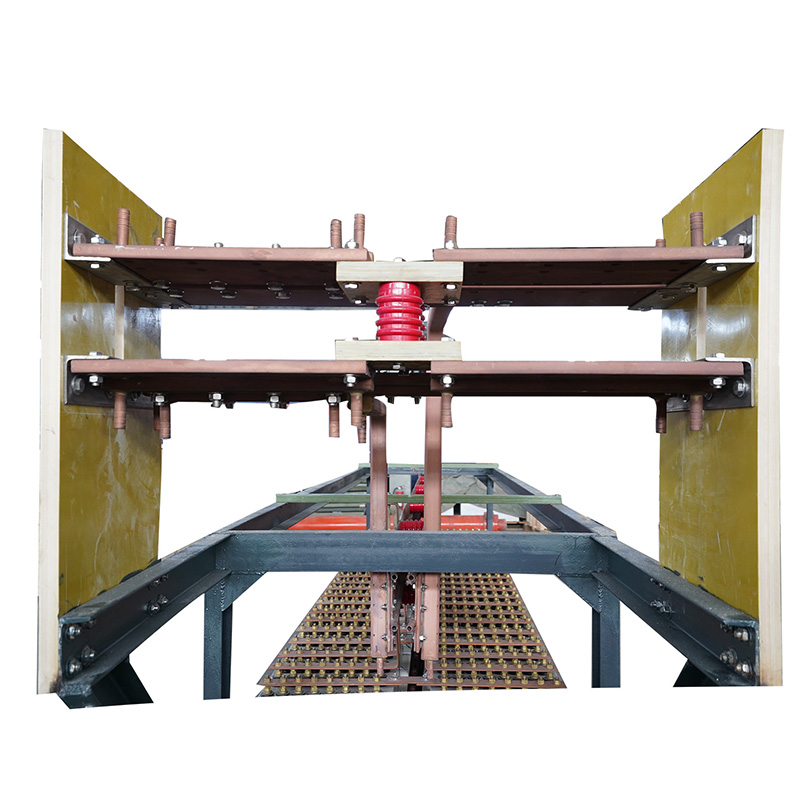

With a focus on precision engineering and cutting-edge technology, Best Brass Induction Melting Furnace Factories has established itself as a top choice for foundries and metalworking industries around the world. The company's induction melting furnaces are renowned for their efficiency, reliability, and cost-effectiveness, making them an essential tool for businesses looking to streamline their metal melting process.

Founded with the goal of revolutionizing the way metal is melted and processed, Best Brass Induction Melting Furnace Factories has continued to push the boundaries of innovation in the industry. The company's team of experienced engineers and technicians are constantly working to develop new and improved furnace designs that deliver exceptional performance and quality.

One of the key factors that sets Best Brass Induction Melting Furnace Factories apart from its competitors is its unwavering commitment to customer satisfaction. The company takes pride in its ability to understand the unique requirements of each customer and provide tailored solutions that meet their specific needs. From initial consultation to after-sales support, Best Brass Induction Melting Furnace Factories is dedicated to ensuring that its customers receive the highest level of service and care.

The company's dedication to quality and excellence is evident in its state-of-the-art manufacturing facilities, which are equipped with the latest technology and machinery. Best Brass Induction Melting Furnace Factories is able to maintain strict quality control measures throughout the production process, ensuring that each furnace that rolls off the assembly line meets the highest standards of performance and durability.

In addition to its commitment to quality, Best Brass Induction Melting Furnace Factories is also deeply committed to sustainability and environmental responsibility. The company understands the importance of reducing its impact on the environment and strives to minimize waste and energy consumption in all aspects of its operations.

As a result of its unwavering dedication to excellence, Best Brass Induction Melting Furnace Factories has earned the trust and loyalty of countless customers across the globe. The company's induction melting furnaces have been widely adopted by foundries and metalworking facilities, where they have proven to be indispensable tools for enhancing operational efficiency and productivity.

Looking ahead, Best Brass Induction Melting Furnace Factories is poised to continue its legacy of excellence and innovation in the industry. The company remains committed to investing in research and development efforts to further enhance the performance and capabilities of its furnaces, as well as to expanding its reach to new markets and industries.

With a strong focus on quality, customer satisfaction, and environmental responsibility, Best Brass Induction Melting Furnace Factories is well-positioned to maintain its status as a leader in the induction melting furnace industry for many years to come. Businesses in need of reliable and efficient metal melting solutions can undoubtedly place their trust in this esteemed company.

Company News & Blog

Affordable and Reliable Smelting Machines Now Available for Sale

Title: Revolutionary Smelting Machine Offers Cutting-Edge Solutions to Industrial SectorIntroduction:In the world of industrial manufacturing, advancements in technology continue to shape the way businesses operate and innovate. One such revolutionary development is the introduction of a state-of-the-art smelting machine that promises to redefine the smelting process. This groundbreaking innovation offers an array of benefits, ranging from improved efficiency and reduced energy consumption to minimal environmental impact. Here, we delve into the features and advantages of this cutting-edge smelting machine and its potential impact on the industrial sector.(Company Introduction):Leading the charge in technological breakthroughs, the renowned company {} has unveiled their latest creation, a next-generation smelting machine. With a long-standing reputation for excellence and innovation, {} has consistently driven the industry forward with their cutting-edge solutions. The introduction of this advanced smelting machine further solidifies their position as pioneers in industrial manufacturing.Impeccable Design and Operations:The newly developed smelting machine boasts an impeccable design that combines precision engineering with advanced automation. This fusion ensures enhanced performance levels while reducing the likelihood of errors. Built with industry-leading materials, the machine ensures durability and longevity, even under demanding operating conditions.Efficiency and Cost Reduction:By integrating the latest technological advancements, the smelting machine offers unmatched efficiency, leading to significant cost reductions for manufacturers. The machine optimizes the smelting process by minimizing resource wastage and maximizing output. Additionally, its intelligent monitoring system enables real-time analysis, allowing for swift identification of any inefficiencies or defects.Reduced Environmental Impact:Recognizing the pressing issue of environmental sustainability, {} has prioritized developing a smelting machine that aligns with eco-friendly practices. The advanced emissions control system incorporated into the machine helps minimize air pollution by filtering harmful substances. Furthermore, the machine's energy-efficient design reduces carbon emissions, contributing to a greener and more sustainable manufacturing process.Enhanced Safety Features:Safety is of utmost importance in modern industrial operations, and {} understands this well. The smelting machine comes equipped with a comprehensive range of safety features to ensure the well-being of workers and prevent accidents. The incorporation of state-of-the-art sensors and early-warning systems guarantee prompt response and risk mitigation, creating a secure work environment.Seamless Integration and Customization:Recognizing the diverse needs of different industries, {} has developed the smelting machine to seamlessly integrate with existing manufacturing processes. Whether it is in the steel, aluminum, or other metal industries, the machine's adaptability allows for easy incorporation and customization. This flexibility ensures minimal disruptions during installation and facilitates smooth operation tailored to specific production requirements.Benefits for Industrial Sector:The introduction of this groundbreaking smelting machine promises to revolutionize the industrial sector on multiple fronts. Manufacturers can experience increased production efficiency, reduced operational costs, and minimized energy consumption. Additionally, the improved environmental impact will contribute to sustainable manufacturing practices, thereby promoting a greener future for the industry.Market Outlook and Potential:With the increasing demand for efficient and sustainable manufacturing practices, the market potential for the {} smelting machine is vast. As more companies seek innovative solutions to improve their production processes, this cutting-edge technology offers a competitive advantage. Moreover, the positive environmental impact aligns perfectly with the growing global emphasis on reducing carbon footprints and adopting eco-friendly practices.Conclusion:The introduction of the state-of-the-art smelting machine by {} marks a significant milestone in the industrial manufacturing sector. Its impeccable design, efficiency, reduced environmental impact, and enhanced safety features position it as a game-changer in the industry. As manufacturers embrace this innovative technology, they can harness its benefits to optimize their operations, reduce costs, and contribute to a sustainable future. With the continued pursuit of excellence and innovation, {} remains at the forefront of transforming the industrial manufacturing landscape.

Powerful Scrap Iron Melting Furnace for Efficient Metal Recycling

Scrap Iron Melting Furnace Revolutionizing Manufacturing ProcessIn response to the growing demand for sustainable manufacturing practices, {Company Name} has introduced a groundbreaking technology that is set to revolutionize the way scrap iron is melted and reused in the manufacturing process. The {Company Name} Scrap Iron Melting Furnace, will not only reduce the environmental impact of manufacturing but also increase efficiency and cost-effectiveness for businesses utilizing this technology.{Company Name} has been a key player in the manufacturing industry for over two decades, specializing in innovative solutions for metal processing and recycling. With a strong commitment to sustainability, the company has been at the forefront of developing eco-friendly technologies that minimize waste and energy consumption without compromising on quality and productivity.The Scrap Iron Melting Furnace is a testament to {Company Name}'s dedication to environmental responsibility and technological advancement. This cutting-edge furnace is designed to melt down scrap iron and other ferrous metals with remarkable efficiency and precision. By utilizing advanced heating and melting techniques, the furnace is able to process scrap iron at a rapid pace while consuming minimal energy, making it a cost-effective and sustainable solution for businesses.One of the key features of the Scrap Iron Melting Furnace is its ability to streamline the manufacturing process by significantly reducing the time and resources required to melt scrap iron. Traditional methods of melting scrap iron often involve lengthy processes and high energy consumption, resulting in a substantial environmental footprint. However, {Company Name}'s furnace is equipped with state-of-the-art technology that not only accelerates the melting process but also minimizes energy usage, making it an ideal choice for businesses aiming to enhance their sustainability profile.Furthermore, the furnace is designed to maintain high levels of performance and durability, ensuring a long lifespan and minimal maintenance requirements. This not only reduces the operational costs for businesses but also contributes to a more sustainable and efficient manufacturing process overall.{Company Name} understands the considerable impact of sustainable practices on the manufacturing industry and recognizes the importance of providing businesses with eco-friendly solutions that meet their operational needs. The Scrap Iron Melting Furnace represents a significant step towards achieving these goals and is poised to contribute to a more sustainable future for the industry.In addition to its environmental benefits, the furnace also offers a cost-effective solution for businesses looking to maximize their operational efficiency. By reducing energy consumption and streamlining the melting process, businesses can enjoy lower operational costs and faster turnaround times, ultimately boosting their bottom line.Furthermore, the Scrap Iron Melting Furnace aligns with {Company Name}'s commitment to innovation and technological advancement. The company's team of experienced engineers and specialists have worked tirelessly to develop this cutting-edge technology, ensuring that it meets the highest standards of quality and performance.With the introduction of the Scrap Iron Melting Furnace, {Company Name} continues to lead the way in sustainable manufacturing solutions, setting a new standard for eco-friendly metal processing technology. As businesses strive to reduce their environmental impact and improve their operational efficiency, this groundbreaking technology is set to make a significant and lasting impact on the industry.{Company Name} remains dedicated to its mission of providing businesses with innovative, sustainable solutions that drive progress and success. The Scrap Iron Melting Furnace represents a leap forward in the company's efforts to transform the manufacturing industry and create a more sustainable future for generations to come.In conclusion, the introduction of the Scrap Iron Melting Furnace by {Company Name} marks a significant milestone in the manufacturing industry, offering businesses an advanced and sustainable solution for scrap iron processing. With its unparalleled efficiency, cost-effectiveness, and environmental benefits, this technology is set to redefine the way businesses approach metal processing and recycling. As {Company Name} continues to champion innovation and sustainability, the Scrap Iron Melting Furnace stands as a testament to the company's unwavering commitment to driving positive change in the industry.

Top Tower Melting Furnace: What You Need to Know

[Tower Melting Furnace] is revolutionizing the way metal is melted and transformed into various products. With its innovative technology and commitment to sustainability, [Tower Melting Furnace] is setting new standards in the metallurgical industry.Based in [location], [Tower Melting Furnace] is a leading manufacturer of melting furnaces and related equipment. The company has a strong reputation for providing high-quality, efficient, and reliable solutions for melting and processing different types of metals.One of the key features that sets [Tower Melting Furnace] apart from its competitors is its advanced melting technology. The company's melting furnaces are designed to provide precise control over the melting process, resulting in higher quality metal products. This technology also allows for faster melting times, reducing energy consumption and increasing productivity.In addition to its cutting-edge technology, [Tower Melting Furnace] is committed to sustainability and environmental responsibility. The company's melting furnaces are designed to minimize emissions and reduce the environmental impact of the melting process. By using cleaner and more efficient melting technologies, [Tower Melting Furnace] is helping its customers reduce their carbon footprint and operate more sustainably.Furthermore, [Tower Melting Furnace] offers a range of melting furnace models to meet the specific needs of its customers. Whether it's melting aluminum, copper, steel, or other metals, the company has a solution for every type of metal melting application. This flexibility and customization options make [Tower Melting Furnace] a preferred choice for metal manufacturers around the world.[Tower Melting Furnace] also provides comprehensive support and service to its customers. From equipment installation and commissioning to ongoing maintenance and technical support, the company is committed to ensuring that its customers get the most out of their melting furnaces. This level of customer service has earned [Tower Melting Furnace] a loyal customer base and a strong reputation in the industry.In line with its commitment to innovation, [Tower Melting Furnace] is continuously investing in research and development to further improve its melting technology. The company is always looking for ways to enhance the performance and efficiency of its melting furnaces, as well as to expand its product offerings to better serve the evolving needs of the metallurgical industry.With its focus on technology, sustainability, customer service, and innovation, it's no surprise that [Tower Melting Furnace] has become a trusted name in the metal melting industry. The company's commitment to excellence and its ability to deliver high-quality, reliable melting solutions have solidified its position as a leader in the market.As [Tower Melting Furnace] continues to grow and expand its presence in the global market, the company remains dedicated to providing top-of-the-line melting technology and exceptional service to its customers. With a strong track record of success and a clear vision for the future, [Tower Melting Furnace] is poised to remain at the forefront of the metallurgical industry for years to come.

Top Tips for Operating a Large Smelting Furnace

Large Smelting Furnace Revolutionizes Industrial Metal ProcessingIn the world of industrial metal processing, efficiency and precision are key factors in ensuring the highest quality output. This is why the introduction of the new Large Smelting Furnace, by leading industrial solutions provider {}, is making waves in the industry. This cutting-edge technology is set to revolutionize the way metals are melted and processed, offering unmatched performance and reliability.The Large Smelting Furnace is designed to accommodate the growing demands of the metal processing industry, with its large capacity and advanced features. With a focus on energy efficiency, this furnace is equipped with state-of-the-art heating elements and insulation materials, ensuring optimal energy utilization and reduced operating costs. This makes it an ideal solution for companies looking to maximize their production output while minimizing their environmental impact.One of the key advantages of the Large Smelting Furnace is its versatility. It is capable of melting a wide range of metals, including steel, iron, aluminum, copper, and other alloys, making it a valuable asset for a variety of industrial applications. Whether it's for casting, forging, or extrusion processes, this furnace is able to meet the diverse needs of metal processing operations.Additionally, the Large Smelting Furnace is equipped with advanced control systems that allow for precise temperature regulation and monitoring. This ensures that the metal being processed is brought to the exact temperature required for its intended use, resulting in superior quality and consistency in the final product. Furthermore, the furnace's robust construction and durable materials guarantee a long service life, providing companies with a reliable and low-maintenance solution for their metal processing needs.In line with {}'s commitment to innovation and customer satisfaction, the Large Smelting Furnace comes with comprehensive technical support and after-sales service. Their team of experts is available to provide assistance with installation, maintenance, and troubleshooting, ensuring that their clients are able to maximize the benefits of this state-of-the-art technology."We are thrilled to introduce the Large Smelting Furnace to the market," says a spokesperson for {}. "This furnace represents a significant advancement in industrial metal processing technology, and we are confident that it will deliver exceptional value to our customers. With its unmatched performance, energy efficiency, and reliability, it is set to become the go-to solution for companies looking to optimize their metal processing operations."The Large Smelting Furnace is already generating significant interest within the industry, with several companies expressing keen interest in adopting this technology to enhance their metal processing capabilities. With its potential to streamline operations, improve quality, and reduce costs, it is poised to become a game-changer in the field of industrial metal processing.As the demand for high-quality metal products continues to grow, the Large Smelting Furnace is perfectly positioned to meet the evolving needs of the industry. With its innovative design, advanced features, and unwavering performance, it is set to redefine the standards of efficiency and precision in industrial metal processing, solidifying {}'s reputation as a leader in delivering cutting-edge solutions for the manufacturing sector.

Discover an Efficient Solution for Your Furnace Needs

Title: Next-Generation Furnace Showcases Groundbreaking Innovations in Casting IndustryIntroduction:In a bid to revolutionize the casting industry, a renowned furnace manufacturer has unveiled its latest product, the groundbreaking Cast Master Furnace. This state-of-the-art furnace is set to redefine the standards of casting technology with its advanced features and efficient performance. The new Cast Master Furnace signifies a significant leap forward, promising unparalleled precision, productivity, and sustainability for casting professionals worldwide.1. Advanced Technology Enhancing Precision:The Cast Master Furnace integrates cutting-edge technology to provide a higher level of precision in the casting process. Incorporating advanced sensors and sophisticated software, the furnace ensures accurate temperature control, preventing overheating or underheating of the metal alloys. This breakthrough technology guarantees exceptional product quality and reduces wastage, enabling casting professionals to achieve the desired results consistently.Furthermore, the furnace's innovative design enables precise monitoring of various parameters such as gas flow, pressure, and air ratios, ensuring optimized combustion. This not only enhances energy efficiency but also minimizes environmental impact, making the Cast Master Furnace a sustainable choice for casting operations.2. Increased Productivity with Smart Features:Recognizing the importance of productivity in the casting industry, the Cast Master Furnace offers a host of smart features that streamline the casting process and reduce downtime. The inclusion of remote monitoring capabilities allows operators to track the furnace's performance, identify potential issues, and make real-time adjustments from a centralized control panel. This remote operation feature enhances efficiency and reduces the need for manual intervention, resulting in improved productivity levels.In addition to remote monitoring, the Cast Master Furnace incorporates an intelligent scheduling system that optimizes the casting cycle based on various factors like alloy composition, mold complexity, and cooling requirements. By automating the scheduling process, the furnace allows for efficient use of resources, thereby maximizing productivity and reducing production costs.3. Sustainability and Energy Efficiency:The Cast Master Furnace is designed to promote sustainable practices and reduce energy consumption in the casting industry. Utilizing state-of-the-art insulation materials, the furnace minimizes heat loss, improving energy efficiency while ensuring a safer working environment.Moreover, the furnace employs a multi-stage filtration system to capture and treat harmful emissions, significantly reducing pollutants released into the atmosphere. This commitment to environmental responsibility aligns with global efforts to mitigate the carbon footprint of industrial processes, making the Cast Master Furnace an environmentally-conscious choice.4. Collaborative Approach for Industry Advancement:The introduction of the Cast Master Furnace demonstrates the manufacturer's commitment to fostering collaboration within the casting industry. The company has actively engaged with casting professionals, incorporating their valuable feedback and insights during the development phase. By combining extensive industry experience with cutting-edge technology, the manufacturer has addressed the specific challenges faced by casting professionals, resulting in an innovative furnace tailored to their unique requirements.Furthermore, the company offers comprehensive technical support, including training programs and prompt assistance from a team of experts. By nurturing a collaborative environment, the manufacturer strives to empower casting professionals with the necessary knowledge and skills to optimize their casting operations effectively.Conclusion:As the casting industry moves towards a more technologically advanced era, the Cast Master Furnace leads the way with its groundbreaking features, exceptional precision, and commitment to sustainability. This advanced furnace promises to revolutionize the casting process, enabling professionals to achieve higher levels of accuracy, productivity, and energy efficiency. With its innovative design and comprehensive support system, the Cast Master Furnace is set to become the choice of casting professionals worldwide, positioning the industry for a brighter and more sustainable future.

Top Crucible Factory in China for Induction Furnaces

China Induction Furnace Crucible Factory Leads the Way in High-Quality CruciblesChina Induction Furnace Crucible Factory, one of the leading manufacturers of high-quality crucibles, has been making significant strides in the production of premium quality crucibles that meet the needs of clients in various industries. The factory, which has been in operation for over 20 years, has become a household name in the industry, thanks to its commitment to innovation and quality.The factory's crucibles are used in a wide range of industries, including metallurgy, foundry, ceramics, chemical, and aerospace. The company has a reputation for producing reliable, cost-effective, and long-lasting crucibles that meet the needs of its clients.China Induction Furnace Crucible Factory uses advanced technology to manufacture its crucibles. The company uses a high-temperature oxidation process for its crucibles that ensures they can withstand high temperatures and pressure. Additionally, the factory has state-of-the-art equipment that allows it to produce crucibles with tight tolerances and accurate dimensions.The company's focus on innovation and quality has helped it to maintain its position as one of the leading crucible manufacturers in the industry. The factory continuously conducts research to develop new materials and production techniques that will help it to offer better products at lower costs. The company also invests heavily in training and development to ensure that its staff has the skills and knowledge needed to produce high-quality crucibles.In addition to producing high-quality crucibles, China Induction Furnace Crucible Factory also offers excellent customer service. The company has a team of professionals that are always ready and willing to answer clients' questions and help them choose the right crucibles for their needs. The team is also available to provide after-sales support to ensure that clients are satisfied with the products they purchase.The factory's commitment to quality is reflected in its ISO 9001 certification. The factory has a comprehensive quality control system that ensures that it meets its clients' requirements and standards. The company also uses high-quality raw materials to produce its crucibles, which guarantees the products' consistency and reliability.China Induction Furnace Crucible Factory's dedication to quality has earned it a loyal customer base, both locally and internationally. The factory exports its products to various countries, including the United States, Canada, and Europe. The company's reputation for producing high-quality crucibles has helped it to build long-lasting relationships with its clients.In conclusion, China Induction Furnace Crucible Factory is a leader in the production of high-quality crucibles. The company's commitment to quality, innovation, and customer service has helped it to maintain its reputation as one of the best crucible manufacturers in the industry. The factory's dedication to research and development ensures that it continues to produce better products at lower costs, making it a reliable partner for businesses in various industries.

Top-rated Industrial Melting Furnace for Efficient Metal Processing

Industrial melting furnaces have become a crucial component of various manufacturing processes. These furnaces are designed to heat metals and other materials to their melting points, enabling them to be molded into various shapes and forms. As such, they are commonly used in industries such as metal casting, foundries, and jewelry making.With increasing demand for reliable and efficient industrial melting furnaces, various manufacturers have emerged in the market. However, one company stands out for its commitment to producing high-quality melting furnaces that meet the needs of diverse industries. This company has gained recognition for its innovative designs, durability, and reliability, making it a leading provider of industrial melting furnaces globally.The industrial melting furnaces produced by this company have a variety of applications across different industrial sectors. They are designed to melt various metals, from aluminum to steel, and enable them to be shaped into different forms for use in different industrial processes. These furnaces come in different sizes and specifications to meet the specific needs of customers, ranging from small-scale foundries to large industrial giants.Moreover, this company designs furnaces that are energy-efficient, environmentally friendly, and safe to use. These features have made it a go-to provider for organizations looking to reduce their energy consumption and cut operational costs. Additionally, the furnaces come with features that improve their functionality and safety, such as electronic controls, specialized cooling systems, and interlocks that prevent accidents in the workplace.The durability of the industrial melting furnaces produced by this company is another factor that sets it apart from its competitors. The furnaces are made of high-quality materials that can withstand high temperatures and resist corrosion over extended periods. This feature allows the furnaces to last long, even in harsh industrial environments with extreme temperatures and chemical exposure.In line with its mission to offer excellent customer service, this company provides comprehensive support and maintenance services to customers worldwide. The company has a team of expert technicians who offer round-the-clock customer support and maintenance services, ensuring that its customers can keep their furnaces working efficiently and effectively. Additionally, the company offers various financing options and payment plans to customers, making it easier for them to afford industrial melting furnaces that meet their needs.ConclusionIndustrial melting furnaces play a critical role in the production process of various industries. As such, it is essential to invest in high-quality furnaces that can provide reliability, durability, and efficiency. This company has carved out a niche in the industry, providing state-of-the-art furnaces that meet the diverse needs of customers in various sectors. Its commitment to innovation, energy efficiency, and safety has earned it a reputation as a leading provider of industrial melting furnaces worldwide. With excellent customer service and maintenance services, this company is poised to provide the best industrial melting furnaces and reliable support to customers today and in the future.

Top-rated Smelting Furnaces: A Complete Guide

: New Smelting Furnace Revolutionizes Metal ProcessingThe metal processing industry is about to undergo a major transformation with the introduction of the latest innovative smelting furnace. This state-of-the-art equipment, developed by [Company Name], is set to revolutionize the way metals are melted and processed, providing a more efficient and environmentally friendly solution for metal manufacturers.[Company Name] is a leading manufacturer of industrial equipment and machinery, with a strong focus on innovation and sustainability. With a long history of developing cutting-edge technologies, [Company Name] has established itself as a pioneer in the industry, continually pushing the boundaries of what is possible in metal processing.The new smelting furnace, which has been in development for several years, represents a significant advancement in the field of metal melting and processing. It is designed to address the key challenges faced by metal manufacturers, including energy efficiency, environmental impact, and overall process improvements.One of the key features of the new smelting furnace is its energy efficiency. The furnace is equipped with advanced heating elements and insulation materials that significantly reduce energy consumption during the melting process. This not only helps to lower operating costs for manufacturers but also reduces the environmental impact of metal processing by cutting down on energy usage and greenhouse gas emissions.In addition to its energy efficiency, the new smelting furnace also boasts improved process automation and control capabilities. The furnace is equipped with state-of-the-art sensors and control systems that allow for precise monitoring and adjustment of the melting process, resulting in higher quality metal output and reduced waste.Furthermore, the new smelting furnace is designed to be more versatile and adaptable to different types of metal processing. It can handle a wide range of metal alloys and compositions, allowing manufacturers to use the furnace for a variety of applications, from casting to forging.The introduction of this new smelting furnace comes at a crucial time for the metal processing industry. With increasing pressure to reduce environmental impact and improve energy efficiency, manufacturers are seeking new solutions to enhance their operations. The new furnace from [Company Name] addresses these needs and provides a viable path towards more sustainable and efficient metal processing.The launch of the new smelting furnace has already generated significant interest among metal manufacturers, with several leading companies expressing their intention to adopt the technology. The potential impact of this innovative equipment on the industry is substantial, and it is expected to drive significant improvements in metal processing efficiency and sustainability.In response to the growing demand for the new smelting furnace, [Company Name] has ramped up production and is working closely with manufacturers to integrate the technology into their operations. The company is also providing comprehensive training and support to ensure that manufacturers can maximize the benefits of the new furnace and optimize their metal processing processes.Overall, the introduction of the new smelting furnace from [Company Name] signals a significant advancement in the field of metal processing. With its focus on energy efficiency, process improvements, and environmental sustainability, the furnace is set to reshape the way metals are melted and processed, offering a more efficient and environmentally friendly solution for the industry. As manufacturers increasingly prioritize sustainable practices and seek to improve their operations, the new smelting furnace will play a crucial role in driving positive change in the metal processing industry for years to come.

Efficient and Effective Melting Furnace Factory for Industrial Use

The Industrial Melting Furnace Factory, a leading manufacturer of industrial melting furnaces, has been making waves in the industry with its state-of-the-art facilities and innovative technologies. With a strong focus on quality and reliability, the company has established itself as a trusted provider of melting furnaces for various industrial applications.Established in [year], the Industrial Melting Furnace Factory has quickly risen to prominence in the industry due to its commitment to excellence and customer satisfaction. The company's melting furnaces are known for their high efficiency, durability, and precision, making them the top choice for a wide range of industrial processes.One of the key factors that sets the Industrial Melting Furnace Factory apart from its competitors is its relentless pursuit of technological advancement. The company is constantly investing in research and development to improve its products and introduce new, cutting-edge technologies to the market. This commitment to innovation has enabled the company to stay ahead of the curve and offer melting furnaces that are unmatched in performance and reliability.In addition to its focus on technology, the Industrial Melting Furnace Factory also places a strong emphasis on quality control and testing. Each melting furnace undergoes rigorous testing and inspection to ensure that it meets the highest standards of quality and reliability. This dedication to quality has earned the company a stellar reputation among its customers, who have come to rely on the Industrial Melting Furnace Factory for their melting furnace needs.Moreover, the Industrial Melting Furnace Factory takes pride in its team of skilled engineers and technicians who are dedicated to delivering the best possible solutions to its customers. The company's staff is highly experienced and knowledgeable in the field of melting furnace technology, and they work closely with clients to understand their specific requirements and provide customized solutions that meet their needs.The Industrial Melting Furnace Factory offers a wide range of melting furnace products to cater to various industrial applications. From small-scale melting furnaces for laboratory use to large-scale industrial furnaces for mass production, the company has a diverse product portfolio to meet the needs of different industries. Furthermore, the company also offers customized solutions for clients with specific requirements, demonstrating its flexibility and ability to adapt to the unique needs of its customers.In addition to its impressive product range, the Industrial Melting Furnace Factory also provides exceptional after-sales service and support to its customers. The company's team of technicians are readily available to provide maintenance, repairs, and technical assistance, ensuring that its clients can rely on their melting furnaces for uninterrupted operation.The company's commitment to excellence, combined with its focus on technology, quality, and customer satisfaction, has helped the Industrial Melting Furnace Factory to establish itself as a leader in the industry. The company's melting furnaces have been widely adopted across various sectors, including metal casting, glass production, and recycling, among others, and have garnered praise for their performance and reliability.As the demand for industrial melting furnaces continues to grow, the Industrial Melting Furnace Factory is poised to expand its presence and reach new milestones. With its unwavering dedication to innovation and customer-centric approach, the company is well-positioned to maintain its leadership in the industry and set new standards for melting furnace technology.In conclusion, the Industrial Melting Furnace Factory has solidified its position as a premier manufacturer of industrial melting furnaces, thanks to its relentless pursuit of excellence, technological innovation, and unwavering commitment to customer satisfaction. As the company continues to push the boundaries of melting furnace technology, it is set to make an even greater impact on the industry, providing reliable and efficient solutions for a wide range of industrial applications.

Top 5 Leading Furnace Factories for the Best Brass Casting

Best Brass Casting Furnace Factories Revolutionizing the Metal Casting IndustryIn today's rapidly advancing world, the demand for high-quality metal castings is on the rise. The brass casting industry, in particular, plays a crucial role in numerous sectors, from automotive to aerospace and many more. To meet these ever-growing market demands, several brass casting furnace factories have emerged as key players in revolutionizing the metal casting industry. This article will delve into the importance of these factories and how they are reshaping the future of metal casting.Brass casting furnace factories are dedicated to producing top-notch equipment and revolutionizing the casting process. Their commitment to quality and innovation has propelled them ahead of their competitors, making them leaders in the industry. These factories tirelessly work towards developing robust and efficient furnaces that enhance the overall casting operations.One of the notable brass casting furnace factories is {}. This factory has established itself as a force to be reckoned with, gaining the trust and loyalty of countless clients worldwide. Their extensive experience combined with state-of-the-art technology has enabled them to achieve remarkable success in the industry.This factory emphasizes precision and efficiency in their furnaces, ensuring that every casting operation yields superior results. They strive to understand the specific requirements of their clients and tailor their furnace solutions accordingly. Whether it is a small-scale foundry or a large-scale industrial operation, the factory provides a diverse range of furnaces to suit different casting needs.Moreover, the factory continually invests in research and development to stay at the forefront of technological advancements. By forging strategic partnerships with leading experts and institutions, they actively participate in the development of new casting techniques and materials. This commitment to innovation allows them to offer furnaces that not only meet industry standards but also surpass them, setting new benchmarks for the casting process.Another significant feature of these brass casting furnace factories is their dedication to environmental sustainability. Recognizing the need for responsible manufacturing, these factories employ eco-friendly practices that minimize waste and reduce energy consumption. They strive to develop energy-efficient furnaces that minimize the carbon footprint without compromising on the quality or efficiency of the casting process. This focus on sustainability aligns with the global call for a greener and more sustainable future.Furthermore, these factories prioritize customer satisfaction by offering comprehensive after-sales services. They understand that the relationship with their clients extends beyond the initial purchase. Hence, they provide technical assistance, maintenance support, and spare parts to ensure the smooth functioning of the furnaces. This commitment to excellent customer service has garnered them a loyal customer base and has solidified their reputation as a reliable and trusted partner in the industry.Looking ahead, these brass casting furnace factories continue to push boundaries and drive advancements in the metal casting industry. By utilizing emerging technologies like artificial intelligence and automation, they aim to streamline the casting process further. This not only improves efficiency but also enhances the overall quality of castings, making them more precise and reliable.In conclusion, the emergence of brass casting furnace factories has revolutionized the metal casting industry. Through their commitment to quality, innovation, and sustainability, these factories are reshaping the future of casting. Their technological advancements and dedication to customer satisfaction set them apart and position them as industry leaders. As the demand for high-quality metal castings continues to grow, these factories will undoubtedly remain pivotal in meeting the evolving market needs.